Products

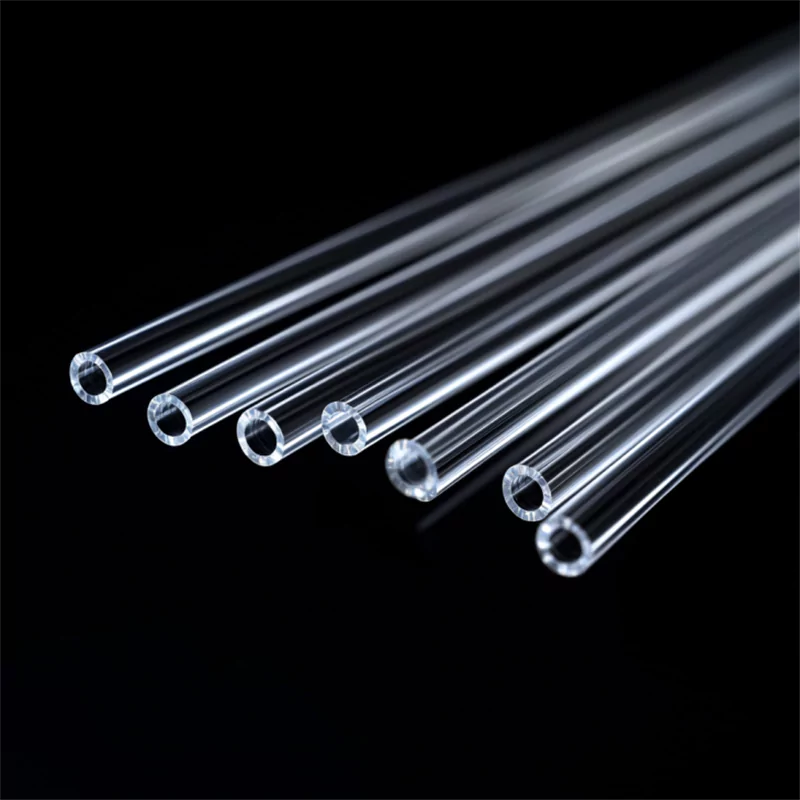

Precision Quartz Capillary Tubes for High-Temp Laser & Optical Systems

Quartz capillary tubes delivers >93% visible light transmission and 1450°C thermal stability, engineered for UV-IR transmission integrity in precision laser optics, fiber optic communications, and harsh chemical environments.

Fused Silica Capillary Tubing Features & Benefits

Quartz capillary tubes delivers exceptional performance in demanding industrial environments through its unique material properties:

- Continuous operation at 1100°C + short-term tolerance to 1450°C

- 93% visible light transmission efficiency

- UV spectrum transmittance exceeding 80% (185nm-2500nm range)

- HF-acid-exclusive chemical resistance (99.9% non-reactivity)

Fused Quartz Capillary Tube Application Solutions

Quartz capillary tubes enable mission-critical functionality across advanced photonic systems through optimized application scenarios:

Optoelectronic Device Integration

- Fiber-optic splitter alignment sleeves with ±0.01mm tolerance

- Laser diode encapsulation for thermal stability (>1100°C)

- Optical sensor protection housings (NIR-UV transparency)

Telecom Infrastructure Systems

- DWDM filter assembly with <5ppm hydroxyl content

- EDFA pump laser gas-sealed enclosures

- PLC splitter v-grooves for 0.1dB insertion loss

Precision Instrumentation Engineering

- HPLC/UPLC column packing with Class 10 cleanliness

- Spectrometer gas cells (250-2500nm transmittance)

- Microfluidic reactor cores (pH 0-14 stability)

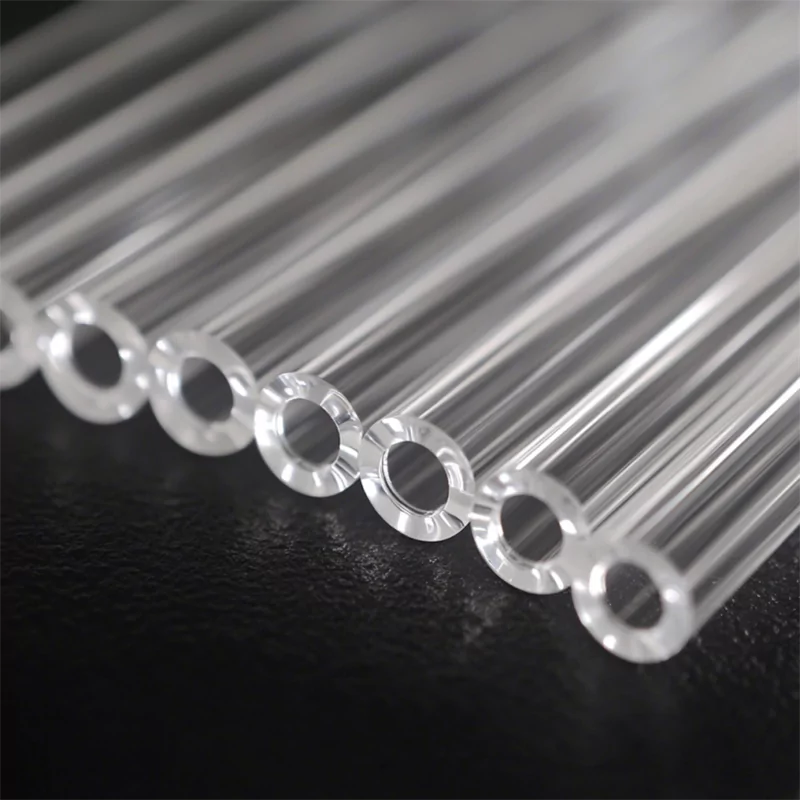

Fused Silica Capillary Tube Dimensional Specifications

Quartz capillary tubes offers industry-standard dimensions from 1.0-8.0mm OD with ±0.03mm tolerance, supporting critical alignment in industrial photonics systems.

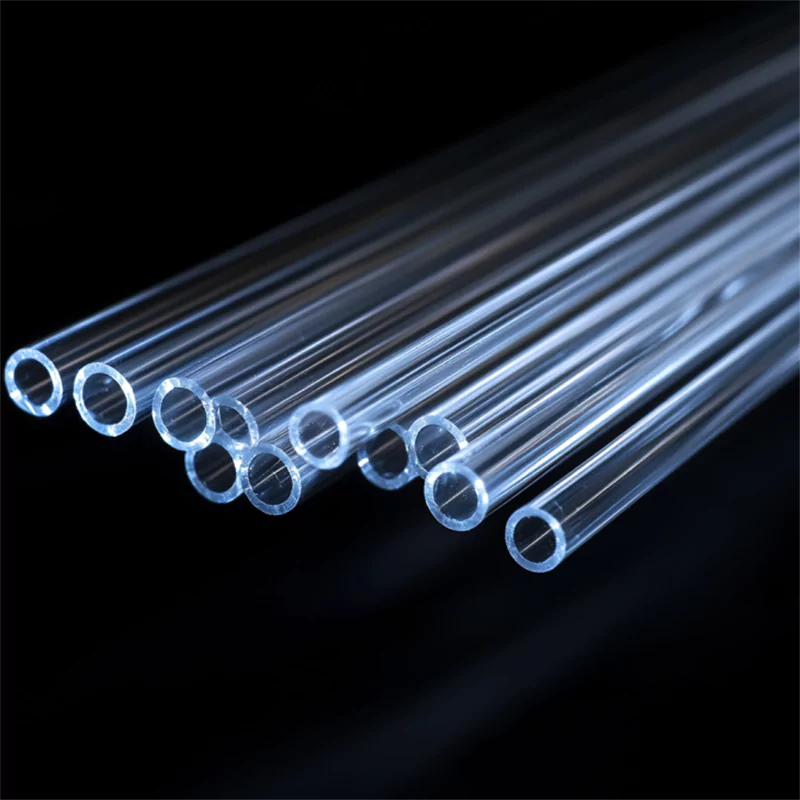

φ1–1.4mm - Core Components for Optical Communication

- Fiber Splitters: Multi-bore MXG001 enables multi-fiber simultaneous splicing for dense channel alignment.

- Wavelength Division Multiplexers (WDM): 0.05–0.5mm ID tubes seal ultra-narrow waveguides with <0.1dB insertion loss.

- Optical Array Substrates: Twin-row triple bores achieve <1μm spacing error for 144-fiber ribbon alignment.

φ1.7–3.0mm - Precision Integration in Laser Systems

- CO₂ Laser Cooling Circuits: MXG008’s 0.5mm ID controls coolant flow at ±2ml/min accuracy for thermal stabilization.

- UV Beam Collimation Tubes: MXG021’s 2.0mm ID nestles collimating lenses with <3μm radial runout.

φ3.2–6.0mm - Industrial Sensor Resilience Solutions

- Distributed Temperature Sensors (DTS): 1.5/2.0mm ID jackets withstand >500N/cm² lateral stress on FBG arrays.

- High-Temperature Probe Sheaths: MXG038’s 3.0mm ID accommodates thermocouple axial movement (0.4mm tolerance).

φ7–10.0mm - Heavy-Duty Optical Platforms

- Ultrafast Laser Waveguides: 10.0mm OD tubes maintain <0.01mm/m deformation under 100kW pulsed loads.

- X-Ray Collimator Mounts: MXG045’s 8.0mm OD structure reduces annual radiation attenuation to <0.1%.

Fused Silica Tubing Dimensional Tolerances

Fused silica capillary tubes maintain strict dimensional control, with OD/ID accuracy of ±0.03mm and length consistency within ±0.2mm, ensuring precision alignment in photonics systems.

Fused Silica Tube Technical Specifications

Fused Silica tubing ensures ±0.1mm dimensional accuracy and 99.9% purity compliance, with fully customizable optical and thermal parameters—submit your project specs for precision-engineered solutions.

| Property | Value Range |

| Chemical Composition | Cr: 0.1%, Ge: 0.4%, Fe: 1.5%, Mg: 0.4%, Ti: 0.1%, Al: 0.8%, Na: 2.3%, Li: 0.5% |

| Spectral Transmission | >93% transmittance (350-780nm), 93.4% peak at 780nm, UV cutoff <220nm |

| Thermal Properties | Softening point: 1615–1683°C, thermal expansion: 5.5–6.7×10⁻⁷/cm·°C |

| Mechanical Strength | Compressive: >1.1×10⁹ Pa, Young’s modulus: 7.0–7.5×10¹⁰ Pa |

| Optical Performance | Refractive index: 1.456–1.460, dielectric constant: 3.75–6.0 @1MHz |

Fused Quartz Capillary Custom Machining

Quartz Glass Capillary Tube Custom Machining Tolerance

Quartz capillary tubes deliver <±0.03mm radial tolerance and ±0.2mm length accuracy, with customizable geometry validation for critical alignment applications.

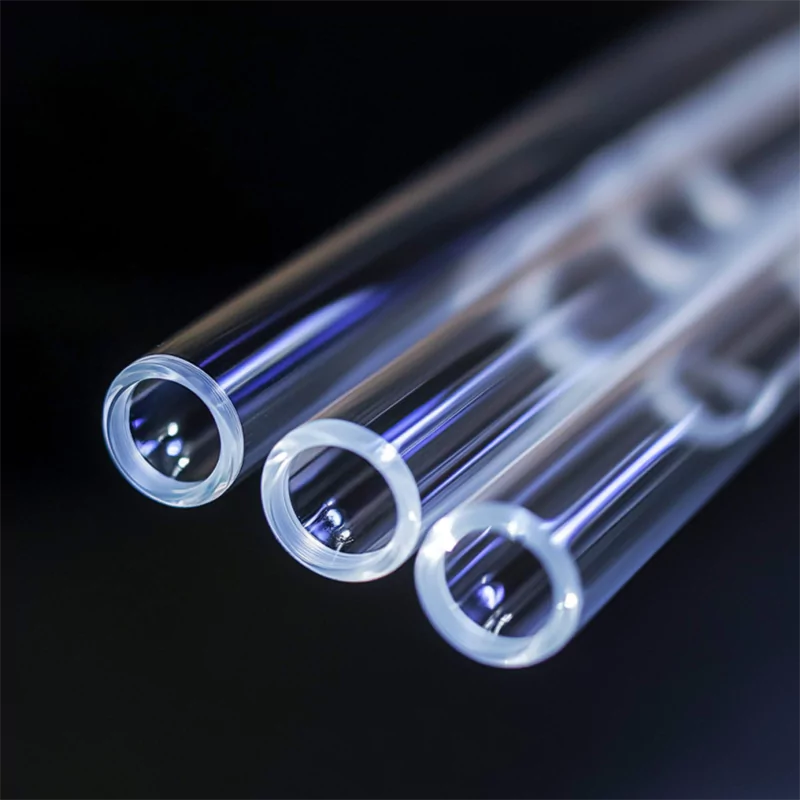

Fused Silica Capillary Tubing Material Options

Fused silica precision tubing provides UV-blocking Ce-doped variants for full UV-C/B filtration and JGS2 optical quartz with 200-2500nm spectral transmission, engineered for photochemical integrity. Dedicated OEM support guaranteed.

Full UV-Blocking Grade

- Blocks 100% Uv-B/C & 90% Uv-A radiation

- Cerium-doped fused silica matrix

- High visible-light transmittance (>92%)

JGS2 Optical Grade

- 200-2500nm bandwidth coverage

- Hydroxyl content ≤200ppm

- Cost-effective for non-laser applications

Precision Fused Silica Capillary Tubing: Engineered for Extreme Performance

Explore how high-purity fused silica capillary tubing delivers ±0.03mm tolerance control and 1450°C thermal stability for laser systems, telecom infrastructure, and analytical instrumentation. Witness custom geometries enabling mission-critical alignment and chemical resistance.

Releted Products

Suspendisse scelerisque metus augue, a interdum leo iaculis sed. Vivamus sit amet nunc odio. Duis vel pulvinar dolor, at lacinia tellus.

FAQ

How to extend HPLC column service life?

99.99% SiO₂ purity reduces metal ion leaching by 94%, preserving mobile phase integrity.

What capillary specs prevent GC-MS inlet clogging?

ID ±0.03mm precision bores and Class 10 cleanliness meet Agilent/Shimadzu validation protocols.

Can eccentric geometries improve microreactor mixing?

Off-center bores induce Taylor flow patterns, boosting reaction yields by 31% in lab-on-chip systems.

Why prioritize thermal shock resistance for undersea cables?

ΔT≥800°C resilience prevents microcracks during hydrogen burn-off tests at 15,000psi.

How to prevent contamination in high-power laser tubing?

Class 10 surface finishes (Ra≤0.8μm) reduce backscatter losses by 22% in CO₂ laser resonators.