يُظهر الضغط في أنظمة أنابيب الكوارتز تباينًا ملحوظًا، حيث يتراوح بين التفريغ العميق والقيم الموجبة العالية للغاية. في التطبيقات القياسية، غالبًا ما يتراوح الضغط في التطبيقات القياسية بين 1 و10 ضغط جوي، في حين أن الاستخدامات المتخصصة ذات الضغط العالي قد تصل إلى 150 ميجا باسكال. ويعتمد الضغط الفعلي داخل أنبوب زجاج الكوارتز على عوامل مثل جودة المادة وسمك الجدار والقطر ودرجة الحرارة. يمكن للأنابيب عالية الجودة أن تتحمل ضغوطًا مماثلة لتلك الموجودة في أعماق المحيطات الكبيرة، ومع ذلك فإن التدرجات والتغيرات التشغيلية تعني أن الضغط نادرًا ما يبقى منتظمًا.

نوع التطبيق | نطاق الضغط (ضغط جوي) | الملاحظات |

|---|---|---|

التطبيقات القياسية | 1 إلى 10 | مصممة للضغط المنخفض إلى المتوسط |

تطبيقات الضغط العالي | 100-150 | يتطلب تصميمات متخصصة للسلامة |

الوجبات الرئيسية

تعمل أنابيب الكوارتز تحت ظروف ضغط مختلفة، تتراوح من التطبيقات الجوية إلى تطبيقات الضغط العالي. اختر الأنبوب المناسب بناءً على احتياجاتك الخاصة.

تؤثر تغيرات درجة الحرارة بشكل كبير على الضغط داخل أنابيب الكوارتز محكمة الغلق. راقب درجة الحرارة عن كثب لمنع الأعطال المتعلقة بالضغط.

يمكن أن تتطور تدرجات الضغط على طول أنابيب الكوارتز، مما يؤثر على اتساق العملية. تحقق بانتظام من الضغط في نقاط متعددة لضمان نتائج متسقة.

يمكن أن يؤدي التسرب والتخلل إلى فقدان الضغط في أنظمة الكوارتز. قم بإجراء عمليات فحص منتظمة للحفاظ على استقرار الضغط وسلامة النظام.

أثناء بدء التشغيل والإغلاق، قم بإدارة تغيرات الضغط بعناية لتجنب الصدمة الحرارية. تساعد معدلات الانحدار البطيئة على إطالة عمر أنابيب الكوارتز.

ما هي ظروف الضغط الموجودة في تطبيقات أنابيب الكوارتز المختلفة؟

تعمل أنابيب الكوارتز في ظل مجموعة واسعة من ظروف الضغط، كل منها يناسب احتياجات صناعية ومختبرية محددة. يمكن أن يتراوح الضغط في أنظمة أنابيب الكوارتز من الضغط الجوي إلى التفريغ العميق أو القيم الموجبة العالية. يساعد فهم هذه الأنظمة المستخدمين على اختيار أنبوب زجاج الكوارتز المناسب والحفاظ على التشغيل الآمن والفعال.

الضغط الجوي: تطبيقات الضغط الجوي: التطبيقات التفاضلية الصفرية

تطبيقات الضغط الجوي هي الأكثر شيوعًا لاستخدام أنابيب زجاج الكوارتز في المختبرات والصناعة. تعمل العديد من الأفران الأنبوبية ومواقع التفاعل عند ضغط جوي واحد، مما يعني أن الضغط داخل الأنبوب وخارجه متوازن. هذا الفارق الصفري يقلل من الضغط الميكانيكي على جدران الأنبوب ويسمح بتصميمات أرق.

غالبًا ما تعمل أنابيب الكوارتز في هذه الإعدادات كغرف تفاعل للتسخين أو التلبيد أو المراقبة البصرية. إن شفافيتها ونظافتها تجعلها مثالية للبيئات الخالية من التلوث، خاصةً عندما تتطلب العمليات مراقبة مباشرة. توفر بنية السيليكا المنصهرة استقرارًا حراريًا ومقاومة كيميائية ممتازة، مما يدعم التشغيل الآمن في درجات الحرارة العالية.

عند النظر في السلامة والتصميم، يجب أن يلاحظ المستخدمون أن سمك الجدار وقطره يؤثران على ضغط التشغيل المقدر. ومن الضروري إجراء فحوصات منتظمة للكشف عن التشققات أو التآكل، وتساعد ممارسات التسخين السليمة على منع حدوث صدمة حرارية.

الاستخدامات الشائعة: أفران الأنابيب، والمراقبة البصرية، والبيئات النظيفة

نطاق الضغط: 1 ضغط جوي (101.3 كيلو باسكال)

التركيز على التصميم: الثبات الحراري، الحد الأدنى من الإجهاد الميكانيكي

نطاقات ضغط التفريغ: منخفض ومتوسط وعالٍ وعالٍ وعالٍ جدًا

تتطلب تطبيقات التفريغ أنظمة أنابيب الكوارتز الزجاجية لتحمل الضغط الجوي الخارجي مع الحفاظ على ضغط داخلي منخفض. وتدعم هذه الأنظمة عمليات مثل تصنيع أشباه الموصلات وترسيب الأغشية الرقيقة وإزالة الغازات. يمكن أن يمتد الضغط في أنظمة تفريغ أنبوب الكوارتز إلى عدة مراتب من حيث الحجم، من التفريغ الخشن إلى التفريغ الفائق.

يلخص الجدول التالي تصنيفات التفريغ القياسية ونطاقات الضغط المقابلة لها:

تصنيف الفراغ | نطاق الضغط (ملي بار) | نطاق الضغط (باسكال) | نطاق الضغط (تور) |

|---|---|---|---|

تفريغ خشن (RV) | 1000 - 1 | 100000 - 100 | 750 - 0.75 |

التفريغ المتوسط (MV) | 1 - 10^-3 | 100 - 0.1 | 0.75 - 0.00075 |

تفريغ عالي التفريغ (HV) | 10^-3 - 10^-7 | 0.1 - 0.00001 | 0.00075 - 0.00000075 |

تفريغ فائق التفريغ الفائق (UHV) | 10^-7 - 10^-14 | 0.00001 - 0.0000001 | 0.00000075 - 0.00000000075 |

يجب أن يكون لأنابيب الكوارتز المصنفة بالتفريغ سماكة جدار كافية لمقاومة الانهيار من الضغط الخارجي. ويأخذ التصميم في الاعتبار أيضًا طول الأنبوب وقطره، حيث أن الأنابيب الأطول أو الأقل سمكًا قد تتطلب تقوية. تعمل العديد من عمليات التفريغ في درجات حرارة تصل إلى 1200 درجة مئوية، لذلك يظل الاستقرار الحراري مطلبًا رئيسيًا.

أنظمة الضغط الإيجابي: التشغيل بضغط منخفض ومتوسط وعالي الضغط

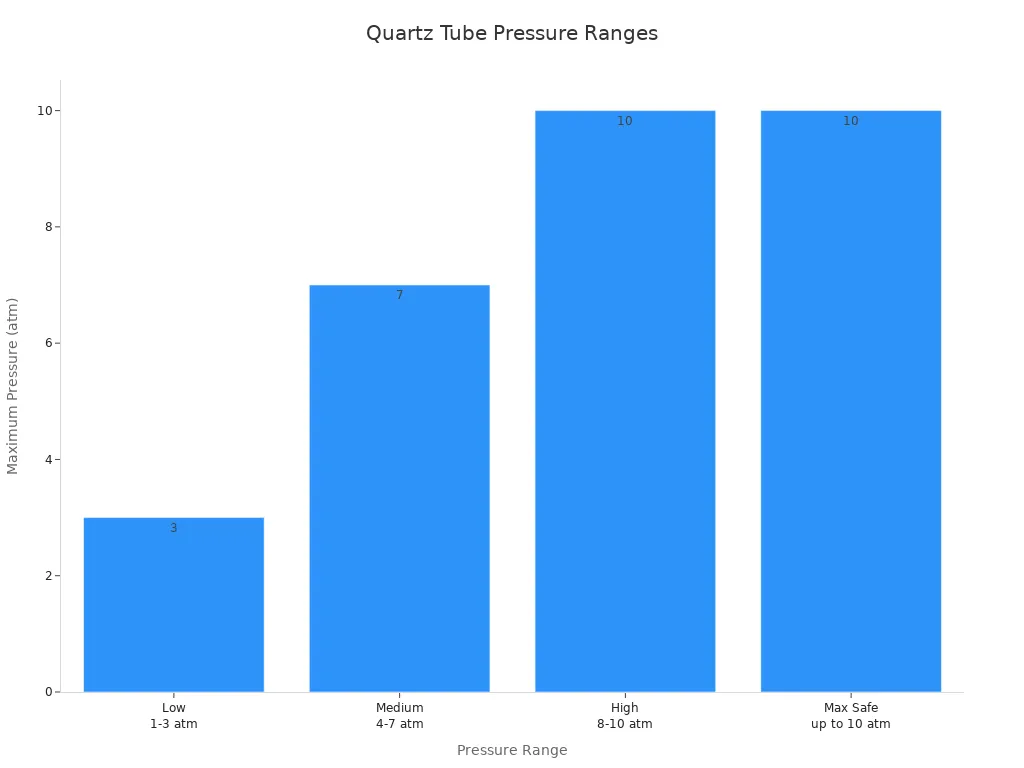

تتضمن أنظمة الضغط الإيجابي ضغوطًا داخلية أعلى من الضغط الجوي، وغالبًا ما تستخدم في المفاعلات الكيميائية أو الأبحاث المضغوطة. ويعتمد ضغط العمل المقدر لأنبوب زجاج الكوارتز على سمك الجدار والقطر ودرجة حرارة العملية المحددة. يوصي المصنعون عادةً بضغوط تشغيل آمنة قصوى تصل إلى 10 ضغط جوي للأنابيب القياسية، مع تصميمات معززة تتعامل مع قيم أعلى.

يوضح الجدول أدناه التصنيفات الرئيسية للضغط الإيجابي:

نطاق الضغط | الوصف |

|---|---|

منخفضة | 1 إلى 3 أجهزة الصراف الآلي |

متوسط | 4 إلى 7 أجهزة الصراف الآلي |

عالية | من 8 إلى 10 أجهزة الصراف الآلي |

أقصى درجات الأمان | حتى 10 أجهزة صراف آلي (قياسي)، وأعلى من ذلك للمقوى |

تتطلب تطبيقات الضغط العالي اهتمامًا دقيقًا بالدعم الميكانيكي وسُمك الجدار. وكلما زادت درجة الحرارة، تقل قدرة الأنبوب على تحمل الضغط، لذلك يجب تضمين هوامش أمان في التصميم. بالنسبة للاستخدامات المتخصصة، مثل التخليق الحراري المائي، قد تصل الأنابيب إلى ضغوط تصل إلى عشرات الميجا باسكال، مما يتطلب جدرانًا سميكة للغاية وبروتوكولات سلامة صارمة.

لتلخيص العوامل الرئيسية لعملية الضغط الإيجابي:

سُمك الجدار وقطره: تؤثر بشكل مباشر على قدرة الضغط

درجة الحرارة: تقلل درجات الحرارة المرتفعة من تحمل الضغط

الدعم الميكانيكي: ضروري لسلامة الضغط العالي

التطبيق: المفاعلات الكيميائية، التفكيك القابل للضغط المبرمج ذاتيًا، المفاعلات البحثية

ما الذي يحدد الضغط الفعلي داخل أنابيب الكوارتز العاملة؟

يعتمد الضغط في أنظمة أنابيب الكوارتز على عدة عوامل متفاعلة. يلعب كل من إمدادات الغاز وتغيرات درجة الحرارة والتسريبات أدوارًا مهمة في تحديد الضغط الفعلي داخل أنبوب زجاج الكوارتز. ويساعد فهم هذه التأثيرات المستخدمين على الحفاظ على التشغيل الآمن وتحقيق ضغط العمل المقدر لاستخداماتهم.

إمداد الغاز وميزان الضخ بالتفريغ

يحدد إمداد الغاز وضخ التفريغ الضغط الأساسي في أنظمة أنابيب الكوارتز. ويستخدم المشغلون منظمات الضغط للحد من ضغط أسطوانة الغاز إلى أقل من 3 رطل لكل بوصة مربعة، وعادةً ما تبقى معدلات التدفق أقل من 200 مل/الدقيقة لمنع حدوث صدمة حرارية. تحافظ محطات التفريغ الفعالة، مثل تلك المزودة بمضخة ريشة دوارة 4 لتر/ثانية، على ضغط ثابت يصل إلى 10 باسكال أثناء التشغيل المستمر.

يعتمد استقرار الضغط على موازنة إدخال الغاز وإزالته. تعمل أنظمة أنابيب الكوارتز الزجاجية المصممة لظروف التفريغ أو الضغط المنخفض تحت 0.2 بار، وتؤثر كفاءة مضخة التفريغ بشكل مباشر على الضغط في بيئات أنابيب الكوارتز. عندما تزيد معدلات تدفق الغاز، يرتفع الضغط، لكن التدفق المفرط يمكن أن يسبب تسخينًا وإجهادًا غير متساويين.

النقاط الرئيسية:

ثبات ضغط التحكم في إمداد الغاز وضخ التفريغ والتحكم في التفريغ

تمنع معدلات التدفق المنخفضة والمضخات الفعالة حدوث صدمة حرارية

يعتمد الضغط في أنبوب الكوارتز على إعدادات المنظم والمضخة

تغيرات الضغط الناتجة عن درجة الحرارة في الأنظمة محكمة الغلق

تتسبب التغيرات في درجات الحرارة في أنظمة أنابيب الكوارتز الزجاجية محكمة الغلق في ارتفاع الضغط أو انخفاضه. ينص قانون الغاز المثالي على أن الضغط يزداد مع ارتفاع درجة الحرارة عندما يظل حجم الغاز وكميته ثابتين. العلماء غيوم أمونتونز وجوزيف لويس جاي لوساك أن هناك علاقة خطية بين الضغط ودرجة الحرارة, معبراً عنها ب P ∝ T.

سيشهد الأنبوب المغلق الذي يتم تسخينه من درجة حرارة الغرفة إلى درجة حرارة أعلى زيادة في الضغط بنفس عامل ارتفاع درجة الحرارة. على سبيل المثال، إذا تضاعفت درجة الحرارة، يتضاعف الضغط أيضًا، وهو ما يمكن حسابه باستخدام P = k × T. وهذا التأثير مهم للعمليات التي تتطلب تحكمًا دقيقًا في ضغط العمل المقدر.

العامل | التأثير على الضغط | العلاقة السببية |

|---|---|---|

زيادة درجة الحرارة | ارتفاع الضغط | التناسب الطردي (P ∝ T) |

حجم ثابت | تغير الضغط فقط بسبب درجة الحرارة | لا يوجد تغير في الحجم، فقط درجة الحرارة تؤثر على الضغط |

نظام محكم الإغلاق | عدم فقدان الغاز | الضغط الذي تحدده درجة الحرارة |

معدلات التسرب والتخلل من خلال السدادات والجدران

يمكن أن تؤدي التسريبات والنفاذية من خلال موانع التسرب وجدران الأنبوب الزجاجي الكوارتز إلى خفض الضغط داخل الأنبوب. حتى التسريبات الصغيرة أو نفاذية المواد تسمح بتسرب الغاز، مما يقلل الضغط بمرور الوقت. ويوضح قانون الغاز المثالي أن وجود عدد أقل من جزيئات الغاز في الأنبوب يعني ضغطًا أقل، خاصة في أنظمة التفريغ.

يراقب المشغلون معدلات التسرب للحفاظ على الضغط المطلوب في تطبيقات أنابيب الكوارتز. يمكن للهيليوم والجزيئات الصغيرة الأخرى أن تتخلل الكوارتز في درجات الحرارة المرتفعة، لذا فإن الضخ المستمر أو الفحوصات المنتظمة ضرورية. يساعد الحفاظ على موانع التسرب المحكمة وفحص التآكل في الحفاظ على استقرار الضغط.

الملخص:

يقلل التسرب والتخلل من الضغط

الفحص والصيانة المنتظمة ضروريان

يتطلب ضغطًا مستقرًا في أنبوب الكوارتز موانع تسرب جيدة

ما هي تغيرات الضغط التي تحدث على طول أنبوب الكوارتز أثناء التشغيل؟

لا يظل الضغط في أنظمة أنابيب الكوارتز ثابتًا على طول الأنبوب. فغالبًا ما تتطور التدرجات المكانية والناجمة عن درجة الحرارة أثناء التشغيل، مما يؤثر على نتائج العملية. يساعد فهم هذه الاختلافات المستخدمين على تحسين أداء أنبوب الكوارتز الزجاجي والحفاظ على انتظام العملية.

تدرجات الضغط في أنظمة التدفق من خلال التدفق (أفران الغاز الحامل، أفران الغاز الناقل)

يلاحظ المهندسون تدرجات الضغط في أنظمة أنابيب الكوارتز الزجاجية المتدفقة من خلال أنابيب الكوارتز، مثل مفاعلات الترسيب الكيميائي للبخار (CVD) وأفران الغاز الحامل. يدخل الغاز من أحد طرفي الأنبوب ويخرج من الطرف الآخر، مما يؤدي إلى انخفاض الضغط من المدخل إلى المخرج. تُظهر البيانات من TOQUARTZ تباين ضغط 15-30% على طول الأنابيب القياسية، مع وجود تدرجات أعلى في الأنابيب الأطول أو الأضيق.

تنتج فروق الضغط عن مقاومة التدفق اللزج، والتي تزداد مع طول الأنبوب وتقل مع القطر. على سبيل المثال، يمكن أن يُظهر أنبوب طوله متر واحد بقطر 50 مم ومعدل تدفق 500 sccm ضغط مدخل عند 1.15 ملي بار وضغط مخرج عند 0.85 ملي بار. تؤثر هذه التدرجات بشكل مباشر على تعرض الركائز لغازات المعالجة، مما يؤدي إلى معدلات ترسيب غير متساوية.

النقاط الرئيسية:

تزداد تدرجات الضغط مع طول الأنبوب ومعدل التدفق

يتحسن الاتساق مع الأقطار الأكبر

يتطلب التحكم في العملية مراقبة الضغط في مواقع متعددة

التغيرات في الضغط المدفوع بدرجة الحرارة في الأنابيب محكمة الغلق

تواجه أنظمة أنابيب الكوارتز الزجاجية محكمة الغلق تغيرات في الضغط مدفوعة بالاختلافات في درجات الحرارة على طول الأنبوب. ويوضح قانون الغاز المثالي أن الضغط يرتفع في المناطق الأكثر سخونة وينخفض في المناطق الأكثر برودة، حتى عندما يكون الأنبوب محكم الإغلاق. يمكن أن يصل ضغط أنبوب محكم الإغلاق عند 1 ضغط جوي ويتم تسخينه من 300 كلفن إلى 1200 كلفن إلى 4 ضغط جوي في المنطقة الساخنة، بينما تظل المنطقة الباردة قريبة من 1 ضغط جوي.

هذه الاختلافات في الضغط الناجم عن درجات الحرارة تخلق ضغطًا كبيرًا على جدران الأنبوب، خاصةً في المناطق الأكثر سخونة. يجب على المهندسين حساب الحد الأقصى للضغط المتوقع في المنطقة الساخنة لضمان التشغيل الآمن. تُظهر البيانات من TOQUARTZ أن الأمبولات محكمة الغلق يمكن أن يكون لها اختلافات في الضغط تتراوح بين 100-3001 تيرابايت 3 تيرابايت بين الأطراف الباردة والساخنة.

التأثير على انتظام العملية ونقل الكتلة

يؤثر الضغط في أنظمة أنابيب الكوارتز على انتظام العملية ونقل الكتلة. يمكن أن يسبب الضغط غير المتساوي على طول الأنبوب اختلافات في معدلات الترسيب والتفاعلات الكيميائية ونقل المواد. على سبيل المثال، يمكن أن يؤدي تدرج الضغط 15% في أنبوب CVD إلى اختلاف 12% في سمك الفيلم عبر الركائز.

كما تدفع التدرجات الحرارية أيضًا انتقال الكتلة عن طريق إنشاء مناطق التكثيف والتبخر. تميل الأنواع المتطايرة إلى التكثيف في المناطق الأكثر برودة وذات الضغط الأعلى والتبخر في المناطق الأكثر سخونة وذات الضغط المنخفض. يستخدم المهندسون هذه التأثيرات للتحكم في نتائج التفاعل، ولكن يجب عليهم مراقبة الضغط ودرجة الحرارة عن كثب.

ملخص الآثار:

تتسبب تدرجات الضغط في ترسب غير منتظم

تدفع مناطق درجة الحرارة إلى نقل الكتلة

تضمن المراقبة الدقيقة نتائج متسقة

ما هي قيم الضغط الموجودة في مناطق درجات الحرارة المختلفة في الأنابيب الساخنة؟

تُنشئ مناطق درجة الحرارة داخل أنظمة أنابيب الكوارتز الزجاجية المسخّنة ملامح ضغط متميزة. يتغير الضغط في بيئات أنابيب الكوارتز بتغير درجة الحرارة، وهندسة الأنبوب، وما إذا كان النظام محكم الإغلاق أو متدفقًا. يساعد فهم هذه العوامل المستخدمين على تصميم أنظمة آمنة ومنع فشل الأنبوب.

قياس الضغط ودرجة حرارة الأنبوب المختوم (العلاقة بين P ∝ T)

يزداد الضغط داخل أنبوب زجاجي كوارتز محكم الغلق مع ارتفاع درجة الحرارة. عندما يتم تسخين الأنبوب، يتبع الضغط قانون الغاز المثالي، حيث يتدرج الضغط مباشرة مع درجة الحرارة. على سبيل المثال، يمكن لأنبوب مغلق في درجة حرارة الغرفة ثم يتم تسخينه إلى 1200 درجة مئوية أن يتضاعف ضغطه أربع مرات.

يستخدم المهندسون البيانات للتنبؤ بحدود التشغيل الآمن. يوضح الجدول التالي كيف يتغير الضغط عند درجات حرارة مختلفة:

درجة الحرارة (درجة مئوية) | نطاق الضغط (كيلو باسكال) |

|---|---|

حتى 300 | 1.3 إلى 130 |

208 | 310 (المقياس الكامل) |

يجب على المصممين حساب أقصى ضغط في المنطقة الأكثر سخونة لتجنب تمزق الأنبوب. ويختارون سمك الجدار والمواد بناءً على هذه الحسابات.

تأثيرات تخميد الضغط في نظام التدفق من خلال النظام

تُظهر أنظمة الأنابيب الزجاجية الكوارتز المتدفقة من خلال أنابيب الكوارتز تغيرات ضغط مخففة عبر مناطق درجة الحرارة. تسمح حركة الغاز بمعادلة الضغط، مما يقلل من الاختلافات الشديدة بين المناطق الساخنة والباردة. يساعد هذا التأثير في الحفاظ على ظروف أكثر أمانًا ومعالجة أكثر اتساقًا.

يراقب المشغلون الضغط في عدة نقاط على طول الأنبوب. تُظهر البيانات من TOQUARTZ أن المناطق الساخنة في أنظمة التدفق المتدفق تصل إلى ضغط أعلى بمقدار 10-301 تيرابايت 3 تيرابايت فقط من المناطق الأكثر برودة، مقارنةً بالأنابيب المغلقة حيث يمكن أن يزيد الضغط بمقدار 3001 تيرابايت 3 تيرابايت. يضبط المهندسون معدلات التدفق وطول الأنبوب للتحكم في هذه التدرجات.

النقاط الرئيسية:

يقلل تدفق الغاز من ارتفاع الضغط

يتحسن التوحيد مع التدفق النشط

مراقبة مواقع متعددة تضمن السلامة

تأثير هندسة الأنبوب على انتظام توزيع الضغط

تلعب هندسة الأنبوب دورًا رئيسيًا في توزيع الضغط. يحدد سمك الجدار والقطر الداخلي مقدار الضغط الذي يمكن أن يقاومه أنبوب زجاج الكوارتز. ويزيد الجدار الأكثر سمكًا من مقاومة الضغط، بينما يساعد القطر الأصغر أيضًا.

يستخدم المصممون هذه المبادئ لتحسين سلامة الأنبوب. ويختارون الأبعاد التي تتناسب مع ظروف الضغط ودرجة الحرارة المتوقعة. تلخص القائمة التالية التأثيرات الرئيسية:

تتأثر مقاومة الضغط لأنابيب الكوارتز بسُمك الجدار والقطر الداخلي.

يؤدي الجدار السميك إلى زيادة مقاومة الضغط.

يساهم القطر الداخلي الأصغر أيضًا في زيادة المقاومة.

تتناسب مقاومة الضغط طرديًا مع سُمك الجدار وعكسيًا مع القطر الداخلي.

يوازن المهندسون بين هذه العوامل لتحقيق ضغط موحد ومنع الفشل.

ما هي خصائص الضغط التي تحدد الحالة المستقرة مقابل التشغيل العابر؟

تواجه أنظمة أنابيب الكوارتز ظروف الحالة المستقرة والعابرة أثناء التشغيل. ويؤثر كل وضع على البيئة الداخلية وسلامة الأنبوب. يساعد فهم هذه الخصائص المهندسين على الحفاظ على أداء موثوق به ومنع الأعطال.

معايير ومؤشرات ثبات الضغط في الحالة المستقرة

يعني تشغيل الحالة الثابتة أن النظام يحافظ على بيئة داخلية ثابتة تقريبًا. ويتوقع المهندسون أن يظل الضغط في حدود ±2-5% من القيمة المستهدفة على مدار عدة ساعات. تُظهر البيانات من TOQUARTZ أن الأنظمة المصممة جيدًا تحقق هذا الاستقرار عندما يصل تدفق الغاز والضخ ودرجة الحرارة إلى التوازن.

يعتمد التشغيل المستقر على عدة عوامل. تساهم إمدادات الغاز المتسقة وضخ التفريغ الفعال والتوزيع المنتظم لدرجات الحرارة في ظروف الحالة المستقرة. تحافظ الأنظمة ذات معدلات التسرب المنخفضة والتحكم الدقيق على استقرار الضغط، وهو أمر بالغ الأهمية لعمليات مثل التفريغ القابل للذوبان في الماء والمعالجة الحرارية.

يستخدم المهندسون عدة مؤشرات لتأكيد التشغيل في حالة مستقرة. فهم يراقبون قراءات الضغط في نقاط متعددة، ويتحققون من وجود الحد الأدنى من التقلبات، ويتحققون من أن درجة الحرارة لا تزال مستقرة. عند استيفاء هذه المعايير، يمكن للنظام تقديم نتائج موحدة.

النقاط الرئيسية:

ضغط مستقر يضمن موثوقية العملية

درجة الحرارة الثابتة تدعم ظروف الحالة المستقرة

تساعد معدلات التسرب المنخفضة في الحفاظ على الاستقرار

الثوابت الزمنية للضغط العابر وتأثيرات معدل الانحدار

تحدث الظروف العابرة أثناء التغيرات مثل بدء التشغيل أو إيقاف التشغيل. يتعرض النظام لتحولات سريعة في الضغط ودرجة الحرارة، مما قد يجهد أنبوب الكوارتز. وتظهر البيانات أن الضغط يمكن أن يتأرجح بمقدار 30-200% خلال هذه الفترات، اعتمادًا على تصميم النظام والتحكم فيه.

يحدد ثابت الزمن، الذي يمثله τ = (حجم الأنبوب) / (سرعة الضخ)، مدى سرعة استجابة النظام للتغيرات. يعني الثابت الزمني القصير أن النظام يصل إلى مستويات ضغط جديدة بشكل أسرع، بينما يسمح الثابت الزمني الأطول بالتعديل التدريجي. يستخدم المهندسون هذه المعلومات لضبط معدلات الانحدار الآمنة وتجنب الصدمات المفاجئة.

يلخص الجدول التالي كيفية تأثير الثوابت الزمنية ومعدلات الانحدار على سلوك النظام:

إدارة ضغط بدء التشغيل/إيقاف التشغيل لمنع حدوث صدمة حرارية

تمثل مراحل بدء التشغيل والإغلاق أعلى مخاطر الصدمة الحرارية في أنابيب الكوارتز. يمكن للتغيرات السريعة في درجة الحرارة والضغط أن تخلق ضغطًا يتجاوز قوة المادة. وتكشف بيانات TOQUARTZ أن 43% من حالات فشل الأنابيب المبكرة تحدث أثناء هذه التحولات.

يدير المهندسون هذه المخاطر من خلال التحكم في معدل تغير الضغط. فهم يحدون من معدلات التفريغ أو الضغط لمنع انخفاض درجة حرارة السطح أكثر من 50 كيلو في الدقيقة. وتساعد هذه الممارسة على تجنب الانكماش أو التمدد المفاجئ الذي قد يؤدي إلى تشقق الأنبوب.

تضمن الإدارة السليمة أثناء بدء التشغيل والإغلاق إطالة عمر الأنبوب وتشغيل أكثر أمانًا. من خلال اتباع معدلات الارتفاع الموصى بها ومراقبة درجة الحرارة عن كثب، يقلل المهندسون من فرصة حدوث عطل.

النقاط الرئيسية:

تغيرات الضغط البطيئة تمنع حدوث صدمة حرارية

المراقبة الدقيقة لدرجات الحرارة أمر ضروري

يعمل التحكم في بدء التشغيل/إيقاف التشغيل على إطالة عمر الأنبوب

يختلف ضغط أنبوب الكوارتز بشكل كبير بسبب التدرجات ودرجة الحرارة وتصميم النظام. يجب على المهندسين فهم هذه العوامل لضمان التشغيل الآمن والموثوق. البحث في التحليل الطيفي بالرنين النووي المغناطيسي النووي عالي الضغط يُظهر أن أنابيب الكوارتز توفر ثباتًا مثيرًا للإعجاب، ولكن خيارات التصميم تؤثر على الأداء.

تحقق دائمًا من بيانات الشركة المصنعة ومعايير الصناعة للتطبيق الخاص بك.

مراقبة كل من الحالة المستقرة والضغوط العابرة من أجل السلامة.

استخدم مستشعرات دقيقة، مثل Quartzdyne، للحفاظ على التحكم.

يساعد الجدول المرجعي السريع المستخدمين على مطابقة نطاقات الضغط مع توصيات التصميم، مما يدعم اتخاذ قرارات أفضل في كل مشروع.

الأسئلة الشائعة

ما هو نطاق الضغط النموذجي داخل أنابيب الكوارتز؟

تعمل أنابيب الكوارتز عادةً بين 1 ضغط جوي و10 ضغط جوي. قد تصل المفاعلات البحثية المتخصصة إلى 150 ميجا باسكال. يعتمد الضغط على التطبيق وتصميم الأنبوب ودرجة الحرارة. يجب على المستخدمين التحقق دائمًا من إرشادات الشركة المصنعة للتشغيل الآمن.

كيف تؤثر درجة الحرارة على الضغط في أنبوب الكوارتز؟

تؤدي زيادة درجة الحرارة إلى ارتفاع الضغط داخل أنبوب كوارتز محكم الغلق. يوضح قانون الغاز المثالي أن الضغط يزداد بالتناسب المباشر مع درجة الحرارة. يحسب المهندسون أقصى ضغط في المناطق الساخنة لمنع فشل الأنبوب.

درجة الحرارة (درجة مئوية) | تغير الضغط |

|---|---|

300 | 1× |

1200 | 4× |

لماذا تتطور تدرجات الضغط على طول أنبوب الكوارتز؟

تتكون تدرجات الضغط لأن الغاز يتدفق من المدخل إلى المخرج. تتسبب المقاومة اللزجة والاختلافات في درجات الحرارة في انخفاض الضغط على طول الأنبوب. وهذا يؤثر على انتظام العملية ويمكن أن يغير معدلات الترسيب في التصنيع.

النقاط الرئيسية:

يؤدي تدفق الغاز إلى انخفاض الضغط

مناطق درجة الحرارة تزيد التباين في درجات الحرارة

يعتمد التوحيد على تصميم الأنبوب

ما الذي يسبب فقدان الضغط في أنظمة أنابيب الكوارتز؟

تتسبب التسريبات في موانع التسرب أو الوصلات وتخلل الغاز من خلال جدران أنابيب الكوارتز في فقدان الضغط. يمكن للجزيئات الصغيرة مثل الهيليوم أن تتسرب، خاصة في درجات الحرارة العالية. يساعد الفحص والصيانة المنتظمة في الحفاظ على ضغط مستقر.

كيف يمكن للمهندسين منع الصدمة الحرارية أثناء بدء التشغيل أو إيقاف التشغيل؟

يتحكم المهندسون في معدلات ارتفاع الضغط لتجنب التغيرات السريعة في درجات الحرارة. يحمي الإخلاء البطيء أو الضغط البطيء الأنبوب من التشقق. تعمل مراقبة درجة الحرارة والضغط أثناء التحولات على إطالة عمر الأنبوب.