Kuvars boru kesme hassasiyetini doğrudan etkileyen çeşitli faktörler vardır. Kesme işlemi, elde edilebilir toleransları, kenar finişini ve mikro çatlak riskini belirler. Duvar kalınlığı, çap ve iç gerilim gibi tüp özellikleri, kesme işleminin stabilitesini ve nihai sonucu etkiler. Kesme işlemi aynı zamanda boruyu hasara yol açmadan sabitlemesi gereken sabitleme ve kuruluma da bağlıdır. Ateşle parlatma ve temizleme dahil olmak üzere kesim sonrası işlemler, kesim işleminin sonucunu iyileştirir. Gereksinimlerin net bir şekilde belirtilmesi, kesim işleminin son kullanım standartlarını karşılamasını sağlar. Kesim işleminin her aşaması, istenen sonuçların elde edilmesinde kritik bir rol oynar.

Önemli Çıkarımlar

İstediğiniz hassasiyeti ve kenar kalitesini elde etmek için doğru kesme yöntemini seçin. CNC elmas testere ve lazer kesim, farklı uygulamalar için benzersiz avantajlar sunar.

Duvar kalınlığı ve çap gibi boru özelliklerinin kesme stabilitesini nasıl etkilediğini anlayın. Sonuçları iyileştirmek için ilerleme hızlarını ve bağlama yöntemlerini bu faktörlere göre ayarlayın.

Kesme sırasında boyutsal stabiliteyi korumak için uygun sabitleme ve kurulum sağlayın. Sıkıştırma basıncını kontrol etmek ve boru hasarını önlemek için kalibre edilmiş sensörler kullanın.

Kenar kalitesini artırmak için ateşle parlatma gibi kesim sonrası işleme tekniklerini uygulayın. Bu adım, mukavemeti geri kazanmak ve spesifikasyonlara uygunluğu sağlamak için çok önemlidir.

Kesim gereksinimlerini ayrıntılı teknik çizimlerle açıkça belirtin. Bu uygulama hataların önlenmesine yardımcı olur ve nihai ürünün kalite standartlarını karşılamasını sağlar.

Hangi Kesim Yöntemleri Farklı Hassasiyet Seviyelerine Ulaşır?

Kuvars boru kesme hassasiyeti seçilen kesme yöntemine, kullanılan ekipmana ve işlem parametrelerine bağlıdır. Her teknik, boyutsal doğruluk, kenar kalitesi ve belirli boru özelliklerine uygunluk açısından benzersiz avantajlar sunar. Bu farklılıkların anlaşılması, kullanıcıların uygulamaları için en iyi yöntemi seçmelerine yardımcı olur.

CNC Elmas Testere - Hassas Yetenekler

CNC elmas testere, kuvars boru kesme hassasiyeti için yüksek hassasiyet sunar. Operatörler, 0,5 ile 1,0 mm arasında kalınlıklara sahip elmas emdirilmiş bıçaklar kullanır ve en iyi sonuçlar için kesme hızını 5-15 mm/dak olarak optimize eder. Bu yöntem, optik bileşenler için ISO 12123 standartlarını karşılayarak 100 mm çap başına ±0,5 mm uzunluk toleransları ve 0,15 mm diklik sağlar.

Elmas bıçağın sertliği, erimiş kuvarsı temiz bir şekilde kesmesini sağlayarak mikro çatlakları ve kenar yontulmasını en aza indirir. CNC kontrolü, tutarlı kesme hızı ve bıçak ilerlemesi sağlayarak insan hatasını azaltır ve tekrarlanabilirliği artırır. Su bazlı soğutma sıvısı 2-5 L/dk'da akarak kesme sıcaklığını 80°C'nin altında tutar ve kuvars tüp kesme hassasiyetini etkileyebilecek termal genleşme hatalarını önler.

CNC elmas testere, yüksek hassasiyet ve tutarlı kenar kalitesi gerektiren uygulamalar için tercih edilen seçenek olmaya devam etmektedir.

Önemli Noktalar:

Benzersiz hassasiyet elmas bıçaklı

Tutarlı kesme hızı ve soğutma sıvısı akışı

ISO 12123 standartlarını karşılar boyutsal doğruluk için

Bu yöntem, zorlu kuvars tüp kesme hassasiyeti ihtiyaçları için güvenilir sonuçlar sağlar.

Lazer Kesim - Kenar Kalitesi Üzerindeki Termal Etkiler

Lazer kesim makinesi teknolojisi, özellikle CO₂ ve fiber lazer kesim makinesi sistemleri ile kuvars tüp kesim hassasiyeti için yüksek hassasiyet sunar. İşlem, kuvarsı eritmek ve buharlaştırmak için odaklanmış lazer ışınları kullanır ve ±0,3 mm uzunluk toleransları ve 0,2-0,4 mm çentik genişlikleri elde eder. Operatörler kesme hızını 5 ila 10 mm/s arasında ayarlar ve farklı boru çapları için gücü 100 ila 300 W arasında ayarlar.

Lazer kesim makinesinden kaynaklanan termal etkiler kenar kalitesini etkileyebilir. Yoğun ısı cüruf ve çapaklara, eğrilmeye, renk bozulmasına ve delaminasyona neden olarak kesimlerin düzgünlüğünü ve hassasiyetini azaltabilir. Pikosaniye fiber lazer kesim makinesi sistemleri, 1 μm'nin altında kenar pürüzlülüğü değerleri ve düşük mikro çatlak oranları üreterek bu etkileri en aza indirirken, standart lazer kesim makinesi kurulumları, kenar kalitesini geri kazanmak için kesim sonrası ateş parlatma veya taşlama gerektirebilir.

Aşağıdaki tabloda termal etkiler ve bunların kuvars tüp kesme hassasiyeti üzerindeki etkileri özetlenmektedir:

Termal Etki | Açıklama | Hassasiyet Üzerindeki Etki |

|---|---|---|

Cüruf ve Çapaklar | Konsantre ısı nedeniyle erimiş malzeme yeniden birikir | Kesimlerin düzgünlüğünü ve doğruluğunu engeller |

Çözgü veya Yağ Konservesi | Düz olmayan yüzeylere neden olan ısıdan kaynaklanan kenar deformasyonu | Kesim kenarlarının hassasiyetini azaltır |

Renk Değişikliği | Kesilen kenarda olası ısı hasarına işaret eden renk değişimi | Estetik kaliteyi etkileyebilir ve bükülme gösterebilir |

Delaminasyon | Lamine malzemelerdeki katmanların aşırı ısıdan ayrılması | Yapısal bütünlük ve hassasiyetten ödün verir |

Lazer kesim makinesi sistemleri yüksek hassasiyet sağlar, ancak kullanıcılar optimum kuvars tüp kesim hassasiyeti için termal etkileri ve işlem sonrası ihtiyaçları göz önünde bulundurmalıdır.

Su Jeti ve Alternatif Kesme Yöntemleri

Su jeti ile kesim yüksek hassasiyet sunar Aşındırıcı parçacıklarla karıştırılmış dar bir su akışı kullanarak kuvars tüp kesme hassasiyeti için. Operatörler, 50 mm çaplı bir tüp için 8-15 dakikalık kesme hızına ulaşır ve kenar kalitesi diğer yöntemlerin çoğundan daha üstündür. İşlem minimum termal gerilim üreterek mikro çatlak oluşumunu ve kenar ufalanmasını azaltır.

Kuvars gibi kırılgan malzemeleri keserken kenar talaşı oluşabilir. Bir destek veya kurban malzeme kullanmak sertliği artırır ve jet akımının iş parçasını doğrudan etkilemesini önleyerek temiz bir kesim sağlar. Su jeti kesimi yaklaşık 1 mm'lik çentik genişliklerine ulaşır ve koniklik genel hassasiyeti etkileyebilse de, işlem yüksek boyutsal doğrulukla sonuçlanır ve genellikle ikincil son işlem gerektirmez.

Önemli Noktalar:

Yüksek hassasiyet ve üstün kenar kalitesi

Minimum termal stres ve azaltılmış mikro çatlaklar

Destek malzemesi kenar yontulmasını önlemeye yardımcı olur

Su jeti kesimi, özellikle termal etkilerin en aza indirilmesi gereken durumlarda kuvars boru kesme hassasiyeti ile öne çıkar.

Boru Özellikleri Kesim Hassasiyetini Nasıl Etkiler?

Kuvars tüp özellikleri kesim kalitesi ve hassasiyetinin belirlenmesinde önemli bir rol oynar. Duvar kalınlığı, çap ve iç gerilimin her biri borunun kesim sırasında nasıl tepki vereceğini ve nihai kenar durumunu etkiler. Bu faktörlerin anlaşılması, üreticilerin tutarlı sonuçlar elde etmesine ve kırılmaları en aza indirmesine yardımcı olur.

Duvar Kalınlığının Kesme Stabilitesi Üzerindeki Etkisi

Et kalınlığı, işleme sırasında boru stabilitesini etkileyerek kesim kalitesini doğrudan etkiler. İnce duvarlı borular genellikle daha fazla titreşir, bu da düzensiz kesimlere ve kırılma riskinin artmasına neden olabilir. Operatörler, kesim kalitesini korumak ve boru hareketini önlemek için ilerleme hızlarını ve sıkıştırma basıncını ayarlamalıdır.

Kalın duvarlı borular titreşime karşı daha fazla direnç sağlayarak daha istikrarlı kesim kalitesi sunar. Bununla birlikte, daha kalın duvarlar aşırı ısınmayı ve bıçak aşınmasını önlemek için daha yavaş ilerleme hızları gerektirir, bu da üretim hızını etkileyebilir. ASTM C693'e göre, 5 mm'nin üzerinde cidara sahip borularda kesim kalitesini korumak ve boyutsal hataları önlemek için dikkatli bir izleme gerekir. TOQUARTZ'dan alınan veriler, ince duvarlı boruların (5 mm) ise daha iyi kesim kalitesini koruduğunu ancak her kesim için daha fazla zaman gerektirdiğini göstermektedir.

Üreticiler, duvar kalınlığına göre uygun ilerleme hızlarını ve bağlama yöntemlerini seçerek kesim kalitesini optimize edebilir.

Önemli Noktalar:

İnce duvarlar titreşimi ve kırılma riskini artırır

Kalın duvarlar, kesim kalitesi için daha yavaş ilerleme hızları gerektirir

Doğru kurulum kesim kalitesini artırır ve kırılmayı azaltır

Çapla İlgili Geometrik Zorluklar

Boru çapı, kesim kalitesini ve hassasiyetini etkileyen geometrik zorluklar yaratır. Küçük çaplı borular, dik olmayan kesimlere ve kırılmalara neden olabilecek dönme ve hareketi önlemek için özel fikstürlemeye ihtiyaç duyar. Büyük çaplı borular daha yüksek güç ve daha düşük travers hızları gerektirir, bu da deformasyon ve ovalite riskini artırır.

Boru çapı değiştikçe ovalleşme ve deformasyon riski artar. Aşağıdaki tablo, çapın deformasyon ve kesim kalitesini nasıl etkilediğini özetlemektedir:

Kanıt Açıklaması | Tüp Çapı ve Deformasyon Üzerindeki Etkisi |

|---|---|

Daha küçük bükülme yarıçapı, boru kesitinde daha büyük deformasyona yol açar. | Boru çapı, kesme kalitesi işlemleri sırasında deformasyonun boyutunu etkiler. |

Ovalleşme, orijinal boru çapının dairesel şeklinden izin verilen maksimum sapmayı temsil eder. | Tüp çapı, ovallik riskini ve kesim kalitesini belirlemede kritik öneme sahiptir. |

Ovalleşme, tüpün çapında bir değişikliğe yol açar. | Boru çapı, deformasyon sürecinden doğrudan etkilenerek kesim kalitesini etkiler. |

Ovallik, işlemden sonra maksimum ve minimum çapların karşılaştırılmasıyla ölçülür. | Bu, boru çapının deformasyon ve kesme kalitesinden nasıl etkilendiğine dair nicel bir ölçüm sağlar. |

Üreticiler boru çapını izlemeli ve kesim kalitesini korumak ve kırılmayı en aza indirmek için sabitleme ve kesim parametrelerini ayarlamalıdır.

İç Stresin Kenar Kalitesi Üzerindeki Etkileri

İç stres kuvars tüpler kesme kalitesini ve kenar durumunu önemli ölçüde etkileyebilir. Yüksek iç gerilime sahip boruların kesim sırasında mikro çatlaklar ve kırılmalar oluşturma olasılığı daha yüksektir ve bu da genel kesim kalitesini düşürür. Operatörler hassas kesimden önce iç gerilimi azaltmak için alevle işlem, HF asit uygulaması ve tavlama fırınları kullanır.

Mikro oluk üretiminin hassas kontrolü, çatlak yayılımını azaltmaya ve kesim kalitesini artırmaya yardımcı olur. Gerilim düzgün bir şekilde yönetilmediğinde, lazer kazıma mikro çatlaklara ve çapaklara yol açabilir, bu da kenar kalitesini düşürür ve kırılma riskini artırır. Geçiş ve gerilme noktası sıcaklıkları arasında kontrollü tavlama, kalıcı gerilimi ortadan kaldırarak daha pürüzsüz kesme yüzeyleri ve daha iyi kesme kalitesi sağlar.

Üreticiler kesimden önce iç gerilimi ölçerek ve azaltarak kesim kalitesini artırabilir.

Önemli Noktalar:

Yüksek iç gerilim mikro çatlakları ve kırılmayı artırır

Tavlama ve alevle işleme kesme kalitesini artırır

Kontrollü gerilim azaltma, daha pürüzsüz kenarlar ve daha iyi kesim kalitesi sağlar

Hangi Fikstürleme ve Kurulum Parametreleri Kesim Hassasiyetini Optimize Eder?

Doğru fikstürleme ve kurulum, kuvars tüp işleme sırasında hassas kesimlerin elde edilmesinde ve hataların azaltılmasında hayati bir rol oynar. Doğru fikstür tasarımı, sıkıştırma basıncı ve hizalama yöntemleri boyutsal stabilite ve tutarlı sonuçlar sağlar. Bakım için en iyi uygulamaları takip ederek üreticiler kuvars tüp bakımını iyileştirebilir ve hem ekipmanın hem de tüplerin ömrünü uzatabilir.

Boyutsal Kararlılık için Fikstür Tasarımı

Fikstür tasarımı, kesim sırasında boyutsal stabiliteyi doğrudan etkiler. İyi tasarlanmış bir fikstür, kuvars tüpü güvenli bir şekilde tutarak yanlışlıklara neden olabilecek hareket ve titreşimi önler. V-blokların veya iki noktalı desteklerin kullanılması tüpün konumunun korunmasına yardımcı olur ve deformasyon riskini azaltır.

Mühendisler genellikle fikstür özelliklerini borunun boyutuna ve duvar kalınlığına göre seçerler. Örneğin, yumuşak uçlara sahip ayarlanabilir V bloklar, sıkıştırma kuvvetini eşit şekilde dağıtarak boru üzerindeki gerilimi en aza indirir. Veriler, gelişmiş bağlama tasarımının proses süresini 35 dakikadan 25 dakikaya düşürebileceğini, homojen duvar kalınlığı ve eksenel bağlama kuvvetinin ise şeklin korunmasına yardımcı olduğunu göstermektedir. Aşağıdaki tablo, fikstür tasarım özelliklerinin boyutsal kararlılığı nasıl etkilediğini vurgulamaktadır:

Tasarım Özelliği | Boyutsal Kararlılık Üzerindeki Etkisi |

|---|---|

Sıkıştırma Kuvveti | Aşırı kuvvet tüpü deforme edebilir |

İki Üst Kullanım | Stabiliteyi artırır, deformasyon riskini azaltır |

Eksenel Sıkıştırma Kuvveti | İlave deformasyonu önler |

Geliştirilmiş Sıkıştırma Tasarımı | Daha hızlı kesim sağlar, deformasyon endişelerini ortadan kaldırır |

Kesimden Kaynaklanan Isı Emilimi | Gerilim salınımına ve deformasyona neden olabilir |

Fikstür tasarımına ve düzenli bakıma odaklanan üreticiler daha iyi kuvars boru bakımı ve daha tutarlı kesim sonuçları elde eder.

Sıkıştırma Basıncı Optimizasyonu

Kuvars tüpün zarar görmesini önlemek için sıkıştırma basıncı dikkatle kontrol edilmelidir. Çok fazla basınç çatlaklara veya deformasyona neden olabilirken, çok az basınç kesme sırasında tüpün kaymasına neden olur. Operatörler, ince duvarlı tüpler için 0,2-0,4 MPa ve daha kalın tüpler için 0,4-0,8 MPa arasındaki basınç aralıklarını ayarlamak için kalibre edilmiş sensörler kullanır.

Sıkıştırma sistemlerinin düzenli bakımı, basıncın güvenli sınırlar içinde kalmasını sağlar. Teknisyenler, kuvars tüp bakım rutinlerinin bir parçası olarak fikstürleri aşınma açısından inceler ve sensörleri yeniden kalibre eder. Bakım ihmal edildiğinde, küçük kaymalar bile işleme sürecini aksatabilir ve tutarsız boyutlara yol açabilir.

Hatalı iş parçası tutma veya sabitleme, kesme sırasında hafif kaymalara yol açabilir ve bu da tutarsız boyutlarla sonuçlanır. Küçük kaymalar bile tüm işleme sürecini kesintiye uğratabilir.

Önemli Noktalar:

Uygun sıkıştırma basıncı tüp hasarını önler

Rutin bakım tutarlı sonuçları destekler

Kalibre edilmiş sensörler güvenli basınç aralıklarının korunmasına yardımcı olur

Üreticiler, uzun ömürlülük için bakım ve en iyi uygulamalara öncelik vererek kelepçelemeyi optimize edebilir ve kuvars tüp bakımını iyileştirebilir.

Takım Kurulumu ve Hizalama Doğrulaması

Takım kurulumu ve hizalama doğrulaması, kesim hassasiyetini korumak için çok önemlidir. Operatörler, borunun kesme bıçağına dik olup olmadığını kontrol etmek için kadranlı göstergeler ve lazer hizalama aletleri kullanır. Bu adım, kesimin düz ve belirtilen toleranslar dahilinde kalmasını sağlar.

Otomatik CNC rutinleri hizalama doğruluğunu daha da artırır. 8.500'den fazla kesim işleminden elde edilen veriler, otomatik hizalamanın kurulumla ilgili hataları ±0,8 mm'den ±0,3 mm'ye düşürdüğünü ve ilk geçiş verimini 87%'den 96%'ye yükselttiğini göstermektedir. Hizalama aletlerinin ve ekipmanlarının düzenli bakımı, kuvars tüp bakımının önemli bir parçasıdır ve sapmayı önlemeye ve güvenilir performans sağlamaya yardımcı olur.

Hizalama Uygulaması | Kesim Hassasiyeti Üzerindeki Etkisi |

|---|---|

Manuel Kurulum | Daha yüksek boyutsal hata riski |

Otomatik CNC Hizalama | Hataları azaltır, verimi artırır |

Düzenli Alet Bakımı | Sürekli doğruluk ve güvenilirlik sağlar |

Tutarlı alet kurulumu, hizalama kontrolleri ve sürekli bakım, hassas kuvars tüp bakımının temelini oluşturur ve uzun ömürlülük için en iyi uygulamaları destekler.

Spesifikasyon Uyumluluğunu Sağlayan Kesim Sonrası İşlemler Nelerdir?

Kesim sonrası işleme, kuvars tüplerin katı boyutsal ve yüzey kalitesi standartlarını karşılamasını sağlar. Ateşle parlatmadan kenar bitirme ve son denetime kadar her adım, uyumluluğun sağlanmasında hayati bir rol oynar. Uygun temizlik ve doğrulama yöntemleri, uzun vadeli performans ve güvenilirliğin korunmasına yardımcı olur.

Ateşle Parlatma Süreci Parametreleri

Ateşle parlatma mikro çatlakları giderir ve kesik kenarları düzleştirerek borunun mukavemetini geri kazandırır. Operatörler hatasız bir yüzey elde etmek için parlatma hızını, bulamaç bileşimini ve pH değerini kontrol eder. 100 rpm parlatma hızı, yüzey pürüzlülüğünü 14 dakika içinde 120 ± 10 nm'den 2,3 nm'ye düşürebilir.

Bulamaç ve pH seviyelerinin dikkatli seçimi sonuçları daha da iyileştirir. pH 8'de 8 wt% SiO2 içeren bir bulamaç kullanıldığında 121,6 nm/dak malzeme kaldırma hızı elde edilirken, 6 wt% CeO2 126,2 nm/dak kaldırma hızıyla 12 dakikada yüzey pürüzlülüğünü 2,1 nm'ye düşürür. Bu parametreler, kenarın hem pürüzsüz hem de güçlü olmasını sağlayarak gelecekteki çatlak veya arıza riskini en aza indirir.

Önemli Noktalar:

Parlatma hızı, bulamaç bileşimi ve pH kritik öneme sahiptir

Doğru parametreler pürüzsüz, hatasız kenarlar sağlar

Ateşle parlatma kenar gücünü ve dayanıklılığını geri kazandırır

Bu işlem, uygulama ihtiyaçlarına bağlı olarak tüpü daha fazla son işlem veya hemen kullanım için hazırlar.

Optik Sınıf Kenar Bitirme Teknikleri

Optik sınıf kenar parlatma, zorlu uygulamalar için ultra pürüzsüz yüzeyler oluşturur. Çanak besleme parlatma, kaput parlatma ve bulamaç jet parlatma gibi teknikler 0,3 nm RMS kadar düşük pürüzlülük değerleri elde edebilir. Manyetoreolojik son işlem ve reaktif plazma parlatma, mikro ve nano düzeyde kontrol için ek seçenekler sunar.

Düşük yüzey pürüzlülüğü, özellikle yarı iletken ve optik kullanımlarda ince kuvars gofretler için gereklidir. Hassas taşlama, parlatma ve kimyasal-mekanik düzleştirme (CMP), 1 nm'nin altında Ra değerlerine ulaşılmasına yardımcı olur. Bu yöntemler, optik performans için kritik olan minimum ışık saçılımı ve yüksek iletim sağlar.

Teknik | Yüzey Kalitesi Üzerindeki Etkisi |

|---|---|

Çanak Besleme Parlatma | Ultra pürüzsüz yüzeyler elde eder (0,3 nm RMS) |

Kaporta Parlatma | 80 nm'ye kadar pürüzlülük üretir |

Bulamaç Jet Parlatma | Daha ince yüzeyler için kullanılır |

Manyetoreolojik Son İşlem | Mikro/nano düzeyde kontrol sağlar |

Reaktif Plazma Parlatma | Temassız, ultra pürüzsüz yüzey |

Bu sonlandırma teknikleri, tüpün optik netlik ve dayanıklılık açısından en yüksek standartları karşılamasını sağlar.

Boyutsal Doğrulama ve Kalite Kontrol

Boyutsal doğrulama ve kalite kontrol, her bir borunun spesifikasyonları karşıladığını teyit eder. Kalite kontrolü, boyutsal doğruluk, şeffaflık ve sertlik kontrolünü içerir. Hassas işleme, borunun kullanım amacı için gerekli standartlara uymasını sağlar.

Kuvars tüp temizliği son incelemeden önce çok önemli bir adımdır. Operatörler dış yüzeyi hafif bir muriatik asit çözeltisiyle (4:1 su/asit) temizler, suyla durular ve yumuşak bir havluyla kurutur. Temizleme sıklığı kullanıma bağlı olduğundan, montajdan önce iç kısım kuru olmalıdır. Dar kuvars tüpleri temizlemenin en güvenli yolu, hasarı önlemek için nazikçe durulama ve kurutmayı içerir.

Yöntem | Açıklama |

|---|---|

Kalite Denetimi | Boyutsal doğruluğu, şeffaflığı ve sertliği test eder |

Hassas İşleme | Hassas boyutlar ve standartlara uygunluk sağlar |

Kuvars Tüp Temizliği | Kirleticileri temizler, denetim doğruluğunu artırır ve uzun süreli kullanımı destekler |

Düzenli temizlik UV iletim kaybını önler ve çatlakları veya conta sorunlarını belirlemeye yardımcı olarak uzun vadeli güvenilirliği ve performansı destekler.

Optimum Sonuçlar için Kesim Gereksinimleri Nasıl Belirlenir?

Kuvars tüpler için kesim gereksinimlerinin belirlenmesi, nihai ürünün hem işlevsel hem de kalite standartlarını karşılamasını sağlar. Net teknik çizimler ve iyi tanımlanmış toleranslar, üreticilerin tutarlı sonuçlar sunmasına yardımcı olur. Maliyet-performans dengelerinin anlaşılması, kullanıcıların projeleri için bilinçli kararlar vermelerini sağlar.

Özel Kesim için Teknik Çizim Özellikleri

Teknik çizimler, doğru kuvars tüp özelleştirmesi için temel oluşturur. Tasarımcılar, kesme işlemini yönlendirmek için toleransları, dikliği ve kenar kaplamasını belirtir. Bu ayrıntılar hataların önlenmesine yardımcı olur ve her tüpün amaçlanan uygulamaya uygun olmasını sağlar.

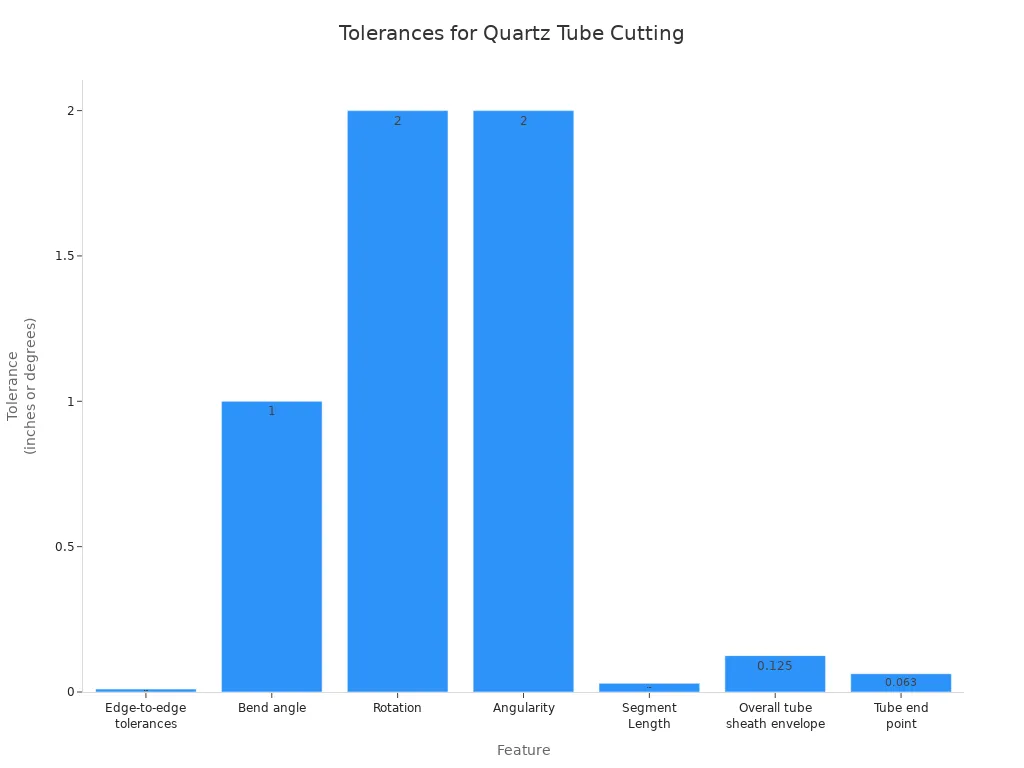

Mühendisler temel özellikleri tanımlamak için standart gösterim kullanırlar. Örneğin, kenardan kenara toleransları +/- .010", bükülme açılarını +/- 1° ve boru uç noktalarını +/- .063" olarak belirleyebilirler. Diklik toleransı, genellikle mikrometre veya inçin binde biri cinsinden ölçülen uygun hizalamayı sağlar. Aşağıdaki tabloda farklı faktörlerin toleransı nasıl etkilediği ve bunun sonucunda boru kalitesi üzerindeki etkisi özetlenmektedir:

Toleransı Etkileyen Faktör | Açıklama |

|---|---|

Form ve boyut toleransı | Standart sayfalarda tanımlanmıştır |

Boyutlar ve sertlik | Küçük kanallar kesim sırasında hareket edebilir |

Isı girişi | Sapmalara ve renk bozulmalarına neden olabilir |

Tasarımcılar ayrıca büyük çapakların ve tırnakların giderileceğini ve tüm boru kıvrımlarında kırışıklık veya buruşukluk olmayacağını belirtirler.

Önemli Noktalar:

Net toleranslar ve diklik kesim işlemine rehberlik eder

Kenar kaplama gereksinimleri kusurları önlemek

Standartlaştırılmış çizimler hataları azaltın ve tutarlılığı artırın

Bu uygulamalar, üreticilerin güvenilir sonuçlar elde etmesine ve bir sonraki üretim aşamasına sorunsuz geçişler yapmasına yardımcı olur.

Hassas Seçimde Maliyet-Performans Ödünleşimleri

Doğru kesme hassasiyeti seviyesinin seçilmesi, performans ihtiyaçları ile proje maliyetlerinin dengelenmesini gerektirir. Daha yüksek hassasiyet genellikle masrafları artırır, ancak güvenilirlik ve uyumun çok önemli olduğu kritik uygulamalar için gerekli olabilir. Karar vericiler, ek yatırıma karşı daha sıkı toleransların faydalarını tartmalıdır.

Yarı iletken veya optik endüstrilerindeki gibi gelişmiş güvenilirlik gerektiren projeler, gelişmiş performans için daha yüksek maliyetleri haklı çıkarır. Buna karşılık, daha az talepkar uygulamalar masraflardan tasarruf etmek için daha geniş toleransları kabul edebilir. Aşağıdaki grafik, farklı özelliklerin hem maliyeti hem de performansı etkileyerek nasıl farklı toleranslar gerektirdiğini göstermektedir:

Önemli Noktalar:

Daha yüksek hassasiyet maliyeti artırır ancak güvenilirliği artırır

Kritik uygulamalar daha sıkı toleranslardan yararlanır

Gevşetilmiş gereksinimlerle maliyet tasarrufu mümkün

Kullanıcılar bu ödünleşimleri anlayarak hem bütçe hem de performans hedeflerine uygun kesim gereksinimlerini belirleyebilirler.

Kuvars tüp kesme hassasiyeti birkaç temel faktöre bağlıdır.

Kesim yöntemi toleransı ve kenar kalitesini etkiler.

Tüp özellikleri duvar kalınlığı ve çap gibi faktörler stabiliteyi etkiler.

Doğru fikstürleme ve kurulum doğru kesimlerin yapılmasını sağlar.

Kesim sonrası işleme Ateşle parlatma ve temizleme gibi işlemler nihai kaliteyi artırır.

En iyi sonuçlar için, kullanıcılar net gereksinimler belirlemeli, maliyeti gerekli hassasiyetle dengelemeli ve her zaman kenar işlemeye öncelik vermelidir. Üreticilerle açık iletişim, daha iyi sonuçlara ve daha uzun ömürlü kuvars tüplere yol açar.

SSS

Kuvars tüpünüzün temizlenmesi gerektiğine dair işaretler nelerdir?

Bulutlu noktalar, ışık geçirgenliğinde azalma veya görünür kalıntılar temizliğin gerekli olduğunu gösterir. Teknisyenler genellikle UV uygulamalarında performans düşüşleri fark ederler. Düzenli denetim bu belirtilerin erken tespit edilmesine yardımcı olur ve uzun vadeli hasarı önler.

Kuvars tüplere zarar veren yaygın hatalar nelerdir?

Metal aletlerin kullanılması, aşırı güç uygulanması veya gerilim azaltma adımlarının atlanması genellikle çatlaklara veya talaşlara neden olur. Teknisyenler bazen kırılma riskini artıran uygun sabitlemeyi göz ardı ederler. Dikkatli kullanım ve doğru kurulum çoğu hasarı önler.

Optik uygulamalar için en iyi kenar kalitesini hangi kesme yöntemi sunar?

İşlem sonrası parlatma ile lazer kesim en pürüzsüz kenarları elde eder. Veriler, parlatma sonrasında 1 nm'nin altındaki kenar pürüzlülüğünü göstermektedir. Bu yöntem yüksek iletim hızlarını ve minimum ışık saçılmasını destekleyerek optik sınıf tüpler için idealdir.

İpucu: Optik kullanım için tüp sipariş etmeden önce her zaman üreticiden kenar kalitesi verilerini talep edin.

Kuvars tüpler için önerilen temizleme işlemi nedir?

Teknisyenler hafif bir asit solüsyonu kullanır, suyla durular ve yumuşak bir havluyla kurutur. Dar borular için nazikçe durulama ve havayla kurutma çizilmeleri önler. Düzenli temizlik berraklığı korur ve uzun vadeli performansı destekler.

Adım | Açıklama | Etki |

|---|---|---|

Asit Yıkama | Kirleticileri temizler | Netliği geri kazandırır |

Su Durulama | Asit kalıntılarını ortadan kaldırır | Korozyonu önler |

Hava Kurusu | Çizilmeleri önler | Yüzeyi korur |

Fırın borusu uygulamaları için hangi tolerans belirtilmelidir?

Çoğu fırın tüpü ±0,5 mm uzunluk toleransı gerektirir. Endüstri standartlarından elde edilen veriler, bunun vakaların 95%'si için uyum ve performans ihtiyaçlarını karşıladığını göstermektedir. Daha sıkı toleranslar maliyeti artırır ancak standart fırın kullanımı için işlevi nadiren iyileştirir.