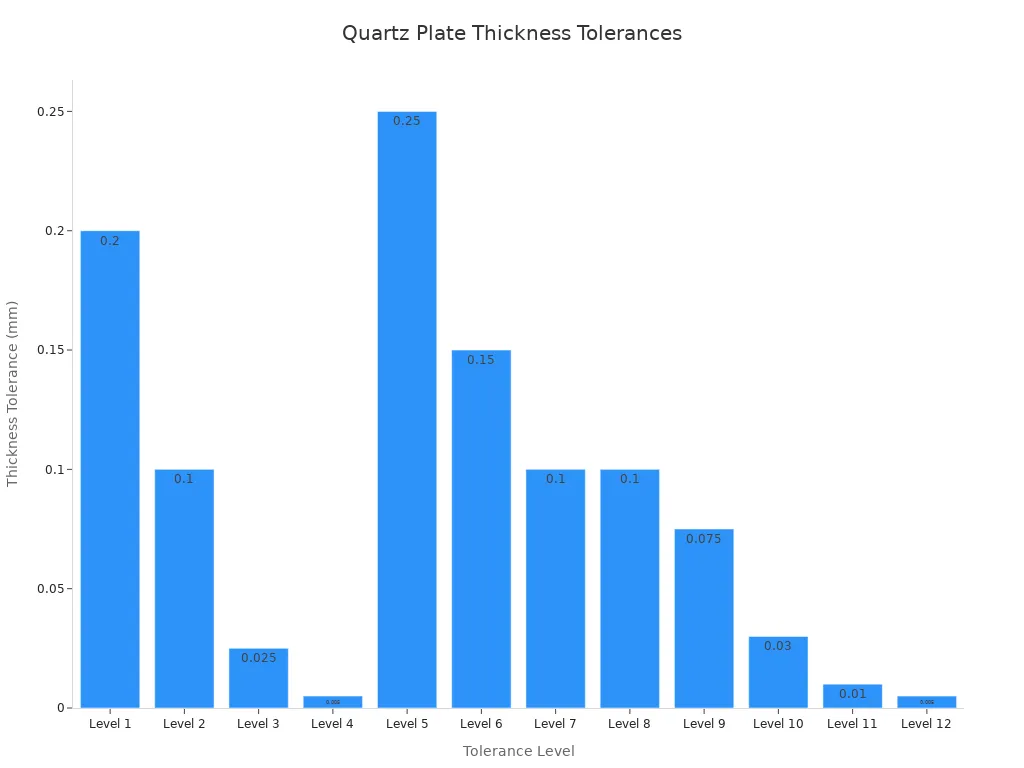

Допуски толщины кварцевых пластин оптического качества играют важную роль в определении качества и надежности современных оптических систем. Для большинства приложений требуются допуски от ±0,01 мм до ±0,1 мм, в зависимости от требований к производительности. В таблице ниже приведены общие уровни допусков для прецизионной оптики:

Уровень толерантности | Допуск на толщину по центру (мм) |

|---|---|

Уровень 4 | ±0.005 |

Уровень 11 | ±0.010 |

Уровень 2 | ±0.1 |

Уровень 5 | ±0.25 |

Более жесткие допуски улучшают оптические характеристики, но при этом увеличивают стоимость производства. Классы прецизионных, высокоточных и базовых допусков влияют как на точность системы, так и на ее стоимость.

Основные выводы

Для обеспечения высокой производительности в оптических системах кварцевые пластины оптического класса должны иметь определенные допуски по толщине. Обычные допуски составляют от ±0,01 мм до ±0,1 мм.

Более жесткие допуски улучшают оптические характеристики, но могут увеличить стоимость производства. Баланс - это ключ к достижению качества и доступности.

Такие области применения, как прецизионная интерферометрия и лазерная оптика, требуют строгого контроля толщины для минимизации ошибок волнового фронта и обеспечения высокого качества результатов.

При производстве полупроводников допуски по толщине ±0,03-0,05 мм имеют решающее значение для поддержания равномерности температуры и максимизации выхода продукции.

Выбор правильного допуска в зависимости от потребностей приложения помогает инженерам избежать лишних затрат и обеспечить оптимальную производительность.

Какие допуски по толщине требуются для прецизионной интерферометрии и лазерной оптики?

Прецизионная интерферометрия и лазерная оптика требуют строгого контроля над кварцевая пластина оптического качества допуски по толщине. Эти допуски непосредственно влияют на погрешность волнового фронта, качество передачи и плоскостность, что крайне важно для высокопроизводительных оптических систем. Отраслевые стандарты, такие как ISO 10110, MIL и ASTM, определяют выбор соответствующих допусков для каждого применения.

Стандартные окна интерферометра: характеристики допуска ±0,25 мм (±0,010")

Стандартные окна интерферометров обычно имеют допуск по толщине ±0,25 мм (±0,010"). Такой уровень допуска гарантирует, что разница оптических путей остается в приемлемых пределах для большинства задач интерферометрии видимой длины волны. Сочетание допуска по толщине, параллельности и плоскостности определяет общую точность измерений.

Окно с допуском ±0,25 мм может поддерживать ошибку волнового фронта в пределах λ/4 при длине волны 632,8 нм, что подходит для общей метрологии и оптических испытаний. В следующей таблице приведены данные о влиянии допуска по толщине на основные оптические параметры:

Аспект | Эффект |

|---|---|

Ошибка волнового фронта | Искривление из-за напряжения покрытия увеличивает погрешность, вызывая смещение фокуса и искажение пятна. |

Трансмиссия | Неровности толщины влияют на ошибку передаваемого волнового фронта (TWE). |

Плоскость | Более толстые подложки противостоят искривлению, улучшая плоскостность. |

Этот уровень допуска позволяет сбалансировать стоимость и производительность, что делает его распространенным выбором для стандартных интерферометрических приложений.

Точность лазерных систем: ±0,13 мм (±0,005") с контролем TTV

В прецизионных лазерных системах часто задается более жесткий допуск по толщине ±0,13 мм (±0,005 дюйма) и требуется строгий контроль общей вариации толщины (TTV). Эти требования помогают минимизировать искажения волнового фронта и тепловое линзирование, которые могут ухудшить качество лазерного луча. Высокомощные и импульсные лазерные системы выигрывают от такой точности, поскольку даже небольшие отклонения толщины могут вызвать значительные различия в оптическом пути.

Производители добиваются таких допусков благодаря передовым методам шлифовки и полировки, а также строгим протоколам контроля. Ниже перечислены основные причины таких спецификаций:

Минимизирует ошибку волнового фронта и тепловое линзирование

Повышает порог лазерно-индуцированного повреждения

Обеспечивает постоянное качество луча по всей апертуре

Соблюдая эти допуски на толщину кварцевых пластин оптического класса, инженеры могут оптимизировать производительность и надежность системы в сложных лазерных приложениях.

Эталонные оптические плоскости: сверхточный допуск ±0,05 мм (±0,002 дюйма)

Эталонные оптические плоскости требуют самых строгих допусков по толщине, часто достигающих ±0,05 мм (±0,002 дюйма). Эти сверхточные компоненты служат калибровочными стандартами для других оптических элементов. Жесткий допуск обеспечивает минимальное расхождение оптического пути и поддерживает высочайший уровень точности измерений.

В таблице ниже приведены типичные допуски для оптических элементов:

Параметр | |

|---|---|

Толщина | 0,2 мм (исходный уровень) |

0,05 мм (точность) | |

0,01 мм (высокая точность) |

Сверхточные допуски на толщину кварцевых пластин оптического класса необходимы для приложений, где даже самое незначительное отклонение может повлиять на калибровку и прослеживаемость.

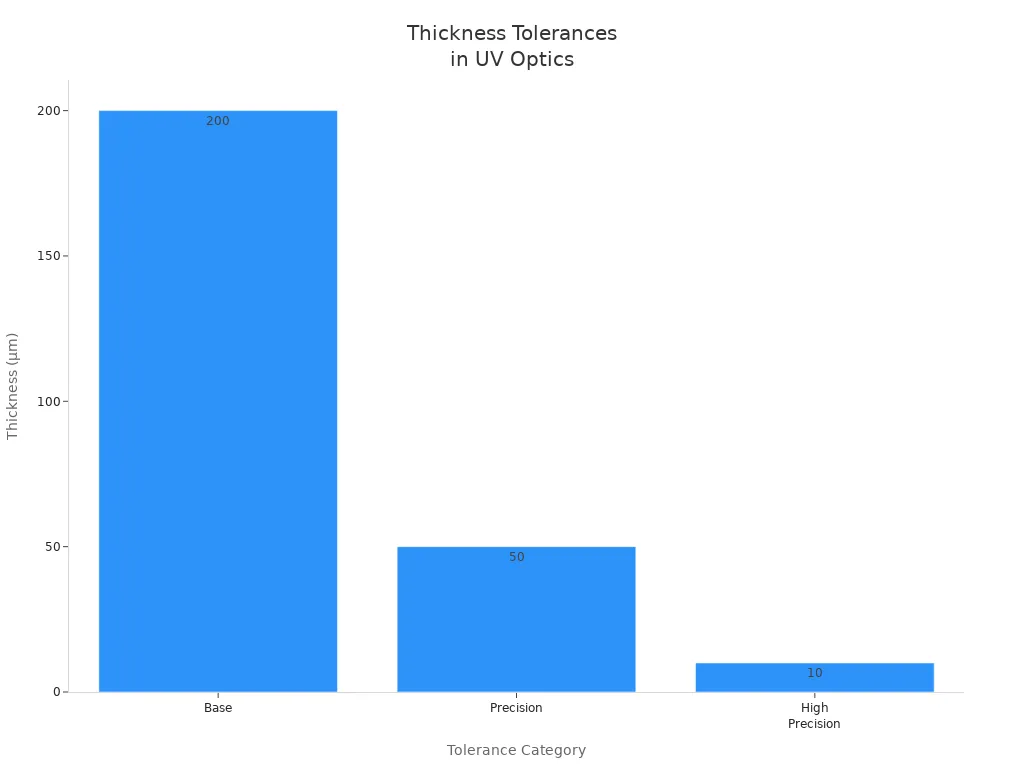

Оптика для ультрафиолетового и глубокого ультрафиолета: более жесткие допуски для более коротких длин волн

Оптика для ультрафиолетового и глубокого ультрафиолета требует еще более жестких допусков по толщине из-за более коротких длин волн. При уменьшении длины волны одно и то же изменение толщины приводит к увеличению разницы оптического пути, что делает точность еще более критичной. Типичные допуски для высокоточной УФ-оптики могут достигать 10 мкм.

Приведенная ниже диаграмма иллюстрирует соотношение между базовыми, прецизионными и высокоточными допусками для УФ-оптики:

Короткие длины волн усиливают влияние ошибок толщины

Для высокоточной УФ-оптики часто требуются допуски 10-50 мкм.

Однородность материала и качество поверхности также становятся более важными

Выбор правильных допусков на толщину кварцевой пластины оптического качества для применения в ультрафиолетовых и глубоких ультрафиолетовых лучах обеспечивает оптимальную производительность и точность измерений.

Какие допуски по толщине требуются для компонентов оборудования для производства полупроводников?

Оборудование для производства полупроводников полагается на точные допуски толщины кварцевых пластин для обеспечения стабильности процесса и выхода продукции. К каждому компоненту, от держателей пластин до смотровых окон, предъявляются уникальные требования, основанные на его назначении и необходимом уровне контроля процесса. Понимание этих различий помогает инженерам выбрать правильную спецификацию, обеспечивающую как производительность, так и экономическую эффективность.

Обработка 300-миллиметровых пластин: ±0,03-0,05 мм для критической тепловой однородности

Engineers specify tight thickness tolerances of ±0.03-0.05mm for 300mm wafer processing components. This level of control is necessary because even small thickness variations can cause significant temperature gradients during rapid thermal processing.

A 0.1mm thickness difference across a 300mm quartz plate can create a thermal mass variation of about 30 grams, leading to temperature differences of 4-6°C during heating cycles. These gradients can reduce device yield by 3-8%, especially in advanced semiconductor nodes below 10nm. To address this, manufacturers use high-purity quartz and advanced grinding techniques to achieve total thickness variation (TTV) below 0.020mm, ensuring uniform heat distribution and stable wafer processing.

A summary table highlights the key relationships:

Технические характеристики | Типичное значение | Причинное воздействие |

|---|---|---|

Допуск по толщине | ±0.03-0.05mm | Controls thermal mass, affects uniformity |

TTV | <0.020mm | Reduces temperature gradients |

Влияние на урожайность | 3-8% loss if out | Direct result of poor thickness control |

200mm wafer processing: ±0.08-0.10mm for standard processes

For 200mm wafer processing, the industry accepts thickness tolerances of ±0.08-0.10mm. These components operate at lower heating rates and have smaller surface areas, so the risk of temperature non-uniformity is reduced compared to 300mm systems.

A 0.1mm thickness variation in a 200mm wafer carrier results in a thermal mass difference of about 8-10 grams, which typically causes a temperature gradient of 2-3°C. This level of variation remains within the acceptable range for most standard semiconductor processes, where device yield is less sensitive to minor temperature fluctuations. Manufacturers often balance cost and performance by choosing this tolerance, which allows for efficient production without sacrificing process reliability.

Key points for 200mm wafer processing:

±0.08-0.10mm tolerance supports standard process control

Lower risk of temperature gradients compared to 300mm systems

Cost-effective for mature semiconductor nodes

Maintains device yield within industry standards

These factors make ±0.08-0.10mm a practical choice for most 200mm wafer applications.

Gas distribution and shower plates: ±0.08mm with flatness control

Gas distribution and shower plates require a thickness tolerance of ±0.08mm, combined with strict flatness control. These plates play a critical role in ensuring uniform gas flow and plasma density during processes like etching and deposition.

A thickness variation greater than ±0.10mm can cause etch rate non-uniformity exceeding 3% across the wafer, directly impacting critical dimension (CD) control and overall chip yield. Flatness specifications, such as ≤0.005" per foot, help maintain a consistent gap between the plate and wafer, which is essential for process repeatability. Manufacturers achieve these tolerances through precision grinding and careful inspection, often using automated measurement systems.

Параметр | Типичное значение | Effect on Process |

|---|---|---|

Допуск по толщине | ±0,08 мм | Maintains gas flow uniformity |

Плоскость | ≤0.005"/ft | Ensures even plasma distribution |

Etch Rate Uniformity | <±3% variation | Directly linked to thickness/flatness |

This combination of thickness and flatness control ensures reliable and repeatable semiconductor processing.

Furnace observation windows: ±0.15mm for non-critical optical viewing

Furnace observation windows use a more relaxed thickness tolerance of ±0.15mm. These components do not directly affect process temperature or device yield, so engineers prioritize mechanical strength and thermal shock resistance over dimensional precision.

A typical observation window may range from 3mm to 20mm in thickness, with the main requirement being the ability to withstand repeated thermal cycling at temperatures up to 1200°C. The wider tolerance reduces manufacturing costs by up to 40% compared to precision-ground components, making it a cost-effective solution for non-critical viewing applications. Most manufacturers focus on purity and durability, ensuring the window remains clear and intact throughout its service life.

Summary of furnace observation window requirements:

±0.15mm tolerance is sufficient for visual monitoring

Mechanical strength and thermal shock resistance take priority

Lower cost compared to precision optical components

No significant impact on process control or yield

This approach allows facilities to allocate resources efficiently while maintaining safe and reliable operation.

What Thickness Tolerances Do Spectroscopy and Analytical Instruments Specify?

Spectroscopy and analytical instruments rely on precise quartz plate thickness tolerances to ensure accurate measurements. The correct tolerance level directly affects absorbance accuracy, calibration, and instrument reliability. Engineers must balance performance needs with manufacturing costs when selecting the right specification.

Standard 10mm cuvettes: ±0.10mm for routine analytical chemistry

Standard 10mm cuvettes use a thickness tolerance of ±0.10mm, which supports most routine laboratory analyses. This tolerance keeps path length errors within ±1%, which matches the typical error budget for absorbance measurements in daily chemical testing. The design ensures reliable results for water quality, biochemical, and educational applications.

A tighter tolerance improves measurement accuracy but increases production costs. For example, reducing the tolerance from ±0.10mm to ±0.05mm can raise costs by 20-40%. The following table shows how path length tolerance impacts absorbance accuracy:

Допуск на длину пути | Impact on Absorbance Accuracy |

|---|---|

±0,01 мм | Minimal error in measurements |

±0,05 мм | Significant error in measurements |

Most laboratories choose ±0.10mm for standard cuvettes because it balances cost and performance for routine analysis.

Short path length cells (1-5mm): ±0.05mm for high-concentration samples

Short path length cells, ranging from 1mm to 5mm, require a tighter thickness tolerance of ±0.05mm. These cells measure high-concentration samples where even small path length errors can cause large inaccuracies in concentration calculations. High-precision cuvettes with ±0.01mm tolerance further reduce measurement uncertainty, but they come with higher costs.

Shorter path lengths amplify the effect of thickness errors

A 0.1mm error in a 1mm cell causes a 10% absorbance error

Tight tolerances ensure reliable results for DNA, protein, and micro-volume analysis

Manufacturers use advanced grinding and inspection techniques to achieve these tolerances. Laboratories select the appropriate tolerance based on the required measurement accuracy and sample type.

Certified reference standards: ±0.02mm for metrological traceability

Certified reference standards demand the strictest thickness tolerances, often reaching ±0.02mm. These standards provide traceability for absorbance measurements and support regulatory compliance. The tight tolerance ensures that path length errors remain below 0.2%, which is critical for calibration and inter-laboratory comparisons.

The following table summarizes the relationship between tolerance and measurement accuracy:

Уровень толерантности | Path Length Error | Absorbance Error |

|---|---|---|

±0.02mm | 0.2% | 0.2% |

±0.10mm | 1% | 1% |

Engineers select these ultra-precise cuvettes for instrument validation, pharmaceutical testing, and certified calibration tasks.

Flow cells and process monitoring: ±0.10-0.15mm with durability priority

Flow cells and process monitoring instruments use thickness tolerances between ±0.10mm and ±0.15mm. These applications prioritize mechanical strength and chemical resistance over absolute dimensional precision. The wider tolerance allows for robust construction, which is essential for continuous operation in harsh environments.

Durability and pressure resistance take priority

Wider tolerances reduce manufacturing costs

Sufficient accuracy for trend monitoring and industrial analysis

Engineers select these tolerances to ensure reliable performance while keeping costs manageable. This approach supports long-term operation in process monitoring systems.

Fluorescence and specialized applications: ±0.08mm with all-sides polishing

Fluorescence and specialized spectroscopy applications require a thickness tolerance of ±0.08mm, combined with all-sides optical polishing. This specification minimizes stray light and background fluorescence, which can interfere with sensitive measurements. The use of ultra-low fluorescence quartz and precise polishing techniques ensures high signal-to-noise ratios.

All-sides polishing reduces background interference

Low-fluorescence quartz improves measurement sensitivity

Tight tolerances support advanced research and diagnostics

These features make the components ideal for fluorescence, Raman, and circular dichroism spectroscopy, where measurement precision is critical.

What Thickness Tolerances Do Industrial High-Temperature and Laboratory Applications Use?

Industrial and laboratory environments often require quartz plates with thickness tolerances that prioritize durability and function over extreme precision. Applications such as microscope slides, furnace windows, and reaction vessels each have unique tolerance needs based on their operational demands. Understanding these requirements helps users select the right quartz plate for both performance and cost efficiency.

Laboratory microscope slides: ±0.15mm for standard biological and materials analysis

Laboratory microscope slides typically use a thickness tolerance of ±0.15mm. This tolerance supports standard biological and materials analysis because most microscope objectives can compensate for small thickness variations through focus adjustment. The main focus remains on surface flatness and optical clarity, which ensures reliable imaging for routine laboratory work.

ISO 8255-1:2017 outlines the dimensional and optical requirements for microscope cover glasses. The standard thickness for most objectives is 0.17mm, and coverglasses come in several grades, including Number 0, 1, 1.5, and 2. High-performance coverglasses can achieve tolerances as tight as ±0.005mm, which minimizes optical aberrations for high numerical aperture objectives.

Deviations from the nominal thickness can cause spherical aberration, especially in advanced imaging. Proper selection of slide and coverglass thickness ensures optimal image quality and reduces measurement errors.

Ключевые моменты:

Standard slides use ±0.15mm tolerance for routine analysis

ISO standards guide coverglass selection

High-NA objectives require tighter tolerances

Correct thickness minimizes optical aberrations

Precision microscopy substrates: ±0.05-0.10mm for quantitative imaging

Precision microscopy substrates require tighter thickness tolerances, usually between ±0.05mm and ±0.10mm. These substrates support quantitative imaging techniques, such as phase contrast and super-resolution microscopy, where even small thickness variations can introduce measurement errors. High numerical aperture objectives often demand coverglass thicknesses of 0.17mm ±0.01mm to maintain image fidelity.

Manufacturers achieve these tolerances through advanced grinding and polishing processes. Substrates with TTV (total thickness variation) below 0.015mm help maintain a uniform imaging plane, which is essential for quantitative results. Data from microscopy standards show that a deviation of just 0.01mm from the nominal thickness can significantly affect spherical aberration and resolution.

Substrate Type | Типичный допуск | Impact on Imaging |

|---|---|---|

Standard Slide | ±0,15 мм | Sufficient for routine use |

Precision Substrate | ±0.05-0.10mm | Required for quantitative work |

High-NA Coverslip | ±0.005-0.01mm | Minimizes aberration |

Selecting the correct substrate ensures accurate imaging and reliable data for advanced microscopy applications.

High-temperature furnace windows: ±0.30mm for visual observation at 1000-1200°C

High-temperature furnace windows use a thickness tolerance of ±0.30mm. These windows must withstand repeated thermal cycling at temperatures up to 1200°C, so mechanical strength and thermal shock resistance take priority over dimensional precision. The wider tolerance allows for robust construction and reduces manufacturing costs by up to 40% compared to precision-ground optics.

Engineers select quartz plates with thicknesses ranging from 5mm to 25mm for furnace windows. The main requirement is that the window remains clear and intact throughout its service life, even after hundreds of heating and cooling cycles. Data from industrial standards show that a ±0.30mm tolerance does not affect visual monitoring but greatly improves durability.

Краткое изложение ключевых моментов:

±0.30mm tolerance supports high-temperature durability

Mechanical strength and shock resistance are critical

Wider tolerance lowers production costs

No impact on visual observation quality

Ultra-thick protective plates: ±0.50mm for extreme-duty applications

Ultra-thick protective plates require the widest thickness tolerances, often ±0.50mm. These plates serve in extreme-duty environments, such as plasma cutting, high-pressure reactors, and explosion-proof barriers. The main function is to provide mechanical strength and chemical resistance rather than optical clarity.

Manufacturers produce these plates in thicknesses from 50mm to 100mm, with tolerances that represent only about 1% of the total thickness. This approach allows for faster production and higher yield rates, which is important for large-scale industrial use. Data from production batches show that relaxing the tolerance from ±0.10mm to ±0.50mm can reduce costs by more than 50%.

Приложение | Typical Thickness | Толерантность | Primary Requirement |

|---|---|---|---|

Plasma/Laser Protection | 50-100mm | ±0.50mm | Механическая прочность |

High-Pressure Windows | 80 мм | ±0.60mm | Impact and pressure resistance |

Selecting ultra-thick plates with relaxed tolerances ensures safety and cost-effectiveness in demanding environments.

Laboratory reaction vessels and cells: ±0.20-0.30mm with chemical compatibility

Laboratory reaction vessels and cells use thickness tolerances between ±0.20mm and ±0.30mm. These components must resist strong acids, bases, and high temperatures, so chemical compatibility and mechanical strength take precedence over tight dimensional control. Most vessels have wall thicknesses from 2mm to 10mm, which provides the necessary durability for repeated use.

Quartz reaction vessels maintain high purity and withstand rapid temperature changes. Engineers specify wider tolerances to keep costs manageable while ensuring the vessel performs reliably in harsh conditions.

Ключевые моменты:

±0.20-0.30mm tolerance balances strength and cost

Chemical resistance is essential

Wider tolerance supports robust vessel design

Suitable for a range of laboratory applications

Selecting the right tolerance for each application ensures both performance and value in industrial and laboratory settings.

How Do Application Requirements and Cost Constraints Determine Optimal Thickness Tolerance Selection?

Selecting the right thickness tolerance for optical-grade quartz plates depends on both the application’s technical needs and the project’s budget. Engineers must analyze how thickness variation affects system performance and weigh the cost impact of tighter tolerances. Understanding these factors helps teams avoid unnecessary expenses while still meeting functional requirements.

Functional requirement analysis: determining minimum acceptable tolerance

Engineers start by identifying the key performance parameters for each application. They use measurement methods such as LVDTs for real-time monitoring in industrial settings, optical systems for high-precision optics, and capacitive sensors for thin films. Each method offers unique advantages, helping engineers match the tolerance to the actual performance need.

Метод измерения | Контекст приложения | Преимущества |

|---|---|---|

LVDTs | Industrial thickness monitoring | High accuracy, cost-effective |

Оптические системы | Precision optical components | Sensitive, ideal for high-precision applications |

Capacitive Sensors | Thin film measurement | Extremely precise |

Inductive Sensors | Non-contact metal measurement | Compact, contamination-resistant |

Typical tolerances for optical components range from ±0.20mm for standard quality to ±0.010mm for high precision. Over-specifying tolerances can increase costs, extend lead times, and raise scrap rates. Many optical systems allow for adjustments that compensate for minor errors, so not every feature needs the tightest tolerance.

Key points to consider:

Analyze how thickness affects performance

Select the widest tolerance that meets requirements

Avoid over-specification to control costs and lead times

Supplier capability verification and quality assurance protocols

Verifying supplier capability ensures that quartz plates meet the specified tolerances and quality standards. Leading suppliers follow ISO 9001:2015 certification, provide traceable compliance documentation, and align quality proofing with customer needs. They also accommodate custom sizes and precision tolerances down to ±0.05mm for high-precision parts.

Quality Assurance Measure | Описание |

|---|---|

Сертифицировано по стандарту ISO 9001:2015 | Обеспечивает стабильное качество продукции |

Прослеживаемая документация по соответствию | Guarantees material traceability |

Подтверждение качества, ориентированное на клиента | Matches validation to client requirements |

Допуски | Precision down to ±0.05mm for select components |

Quality assurance protocols include Certificates of Conformance, Material Test Reports, and Dimensional Inspection Reports. In-process quality checks and supplier audits are recommended for critical applications. Demanding rigorous QA documentation helps maintain reliability and traceability.

Резюме лучших практик:

Request detailed QA documentation

Ask about in-process quality checks

Conduct supplier audits for critical parts

By following these steps, engineers can confidently select quartz plates that balance performance, quality, and cost.

Selecting the right optical-grade quartz plate thickness tolerances depends on the application. The table below shows typical tolerances and references:

Type of Plate | Допуск по толщине | Стандартная ссылка |

|---|---|---|

Furnace Plate | ±0,5 мм | ISO 9050 |

Analytical Window | ±0.10 mm | ISO 9050 |

Прецизионная оптика | ±0,05 мм | ISO 9050 |

Matching tolerance to application needs improves performance and controls cost.

Engineers should consult industry standards and work with qualified suppliers for best results.

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

What is the most common thickness tolerance for optical-grade quartz plates?

Manufacturers usually specify ±0.10mm for standard optical-grade quartz plates. This tolerance meets most laboratory and industrial needs. Engineers select tighter tolerances for high-precision applications.

What factors determine the required thickness tolerance?

Engineers consider application type, performance requirements, and cost constraints. Optical systems need tighter tolerances for accuracy. Industrial uses prioritize durability and cost.

Совет: Always match tolerance to the functional need for best results.

What happens if the tolerance is too tight for the application?

Unnecessarily tight tolerances increase production costs and lead times. Most systems do not benefit from extra precision. Engineers should avoid over-specifying tolerances.

Уровень толерантности | Влияние на стоимость | Время выполнения |

|---|---|---|

Стандарт | Низкий | Короткие |

Сверхточный | Высокий | Длинный |

What quality assurance measures verify thickness tolerance?

Suppliers use calibrated measurement tools, ISO certifications, and inspection reports. Engineers request Certificates of Conformance and material test data for critical parts.

Ключевые моменты:

Certified measurements ensure accuracy

Documentation supports traceability

Regular audits maintain quality

What is total thickness variation (TTV) and why does it matter?

Total thickness variation (TTV) measures the difference between the thickest and thinnest points on a plate. Low TTV improves uniformity in optical and thermal applications.

Low TTV: Лучшая производительность

High TTV: Risk of uneven heating or optical distortion