Los grados de material de los discos de cuarzo para aplicaciones ópticas uv visible infrarrojo muestran claras diferencias en pureza, transmisión y absorción. Estas diferencias determinan qué grado funciona mejor para cada rango de longitud de onda. Por ejemplo, el cuarzo de tipo 214 permite una fuerte transmisión uv por debajo de 160 nm y una absorción mínima a 245 nm, lo que lo hace ideal para óptica uv profunda. En cambio, el tipo 219 contiene más titanio, lo que provoca una mayor absorción y desplaza el corte uv a longitudes de onda más largas. El tipo 124 presenta un buen rendimiento en el infrarrojo, con una baja absorción en la banda de agua de 2,73 µm. La selección del grado adecuado garantiza el máximo rendimiento óptico y rentabilidad.

Tipo de cuarzo | Corte UV (nm) | Transmisión IR (µm) | Características de absorción |

|---|---|---|---|

Tipo 214 | < 160 | Hasta 4,0 | Absorción mínima a 245 nm, sin absorción debida a iones hidroxilo |

Tipo 219 | ~230 | 4.5 - 5.0 | Contiene ~100 ppm de Ti, desplaza el corte UV a longitudes de onda más largas. |

Tipo 124 | N/A | Hasta 4,0 | Eficaz para el infrarrojo, absorción mínima en la banda del agua a 2,73 µm |

Principales conclusiones

Seleccione sílice fundida de grado UV para aplicaciones ultravioletas profundas por debajo de 250 nm. Su bajo contenido en impurezas metálicas garantiza una transmisión y un rendimiento elevados.

La sílice fundida de grado óptico es ideal para aplicaciones en el visible y el infrarrojo cercano. Ofrece un valor excelente y una alta transmisión sin necesidad de capacidades UV profundas.

La sílice fundida de grado IR destaca en aplicaciones de infrarrojos por su bajo contenido en hidroxilo. Esto minimiza las pérdidas por absorción y mejora la transmisión en el rango infrarrojo.

Comprender las diferencias entre los grados de cuarzo ayuda a los ingenieros a elegir el material adecuado para necesidades ópticas específicas, maximizando el rendimiento y la rentabilidad.

Adapte siempre el grado de cuarzo a la gama de longitudes de onda prevista. Esto garantiza un rendimiento óptico y una gestión presupuestaria óptimos.

¿Qué diferencias de grado de material definen el disco de cuarzo de grado UV para aplicaciones de ultravioleta profundo (185-400 nm)?

Los grados de material de los discos de cuarzo uv aplicaciones ópticas infrarrojas visibles muestran claras diferencias en su capacidad para transmitir luz ultravioleta profunda. La sílice fundida de grado UV destaca porque combina una gran pureza con una fabricación avanzada, lo que la convierte en la mejor elección para los exigentes sistemas ópticos UV. Comprender las características únicas de cada grado ayuda a ingenieros y científicos a seleccionar las obleas de sílice fundida adecuadas para sus aplicaciones.

Diferencias en el contenido de impurezas metálicas: Grado UV (<1 ppm) frente a grado óptico (10-20 ppm)

La sílice fundida de grado UV contiene menos de 1 ppm de impurezas metálicas, mientras que los grados ópticos suelen tener entre 10 y 20 ppm. Este bajo nivel de impurezas en la sílice fundida de grado UV evita la absorción no deseada en el rango UV profundo y mantiene el borde de absorción en longitudes de onda más cortas. La sílice fundida de alta pureza garantiza que la disco de cuarzo grados de material uv visible infrarrojo aplicaciones ópticas cumplen estrictos requisitos ópticos.

Cuando las impurezas metálicas superan 1 ppm, el corte UV se desplaza a longitudes de onda más largas y disminuye la resistencia a la solarización. Esto significa que las obleas de sílice fundida de grado óptico no pueden igualar el rendimiento de la sílice fundida de grado UV en entornos UV profundos. La diferencia en el contenido de impurezas afecta directamente tanto a la transmisión como a la durabilidad a largo plazo del material.

Aspecto | Grado UV (<1 ppm) | Grado óptico (10-20 ppm) | Causalidad/Impacto |

|---|---|---|---|

Corte UV | Longitudes de onda más cortas | Longitudes de onda más largas | Las impurezas más altas desplazan el corte y reducen el rendimiento |

Resistencia a la solarización | Alta | Baja | La pureza aumenta la resistencia al oscurecimiento inducido por los rayos UV |

Comparación del proceso de fabricación: Deposición de vapor sintético frente a fusión de cristales naturales

Los fabricantes producen sílice fundida de grado uv mediante deposición sintética de vapor, que crea obleas de sílice fundida ultrapuras. Este proceso utiliza materias primas de alta calidad y técnicas avanzadas para conseguir la máxima pureza y las mejores propiedades ópticas. En cambio, los grados ópticos proceden de la fusión eléctrica de cristales de cuarzo natural, que introduce más impurezas.

El proceso sintético de la sílice fundida de grado UV aumenta los costes de producción y limita la disponibilidad, pero ofrece un rendimiento inigualable para aplicaciones ópticas de UV profundo. Los pasos de precisión, como el corte por láser y el alisado de bordes, aumentan aún más el coste, pero garantizan que el producto final cumpla normas estrictas. La elección del método de fabricación determina tanto la calidad como el precio del material del disco de cuarzo de grado uv para aplicaciones ópticas de infrarrojo visible.

Puntos clave:

La deposición sintética de vapor produce obleas de sílice fundida de gran pureza.

La fusión eléctrica del cuarzo natural aumenta los niveles de impurezas.

El método de fabricación influye tanto en el coste como en el rendimiento óptico.

Requisitos de resistencia a la solarización para la exposición a rayos UV de alta intensidad

La sílice fundida de grado UV resiste la solarización, que es el oscurecimiento permanente causado por la exposición intensa a los rayos UV. Esta propiedad es esencial para los componentes ópticos utilizados en sistemas UV de alta potencia, como láseres de excímeros y herramientas litográficas. El bajo contenido de impurezas metálicas y la estructura de alta pureza de las obleas de sílice fundida de grado UV impiden la formación de centros de color que absorben la luz.

La resistencia a la solarización permite que la sílice fundida de grado uv mantenga una alta transmisión incluso después de miles de horas bajo una luz ultravioleta intensa. Los grados ópticos, con mayores niveles de impurezas, pierden transparencia más rápidamente y pueden fallar en entornos exigentes. Los ingenieros confían en la sílice fundida de grado UV para aplicaciones en las que la claridad óptica a largo plazo es fundamental.

Requisito | Sílice fundida de grado UV | Sílice fundida de grado óptico | Causalidad/Impacto |

|---|---|---|---|

Resistencia a la solarización | Excelente | Moderado | Su gran pureza evita la formación de centros de color |

Transmisión UV a largo plazo | Mantenido | Disminuye | Las impurezas aceleran el oscurecimiento |

Ejemplos de aplicaciones UV: Láseres de excímeros, litografía DUV, espectroscopia UV

Las obleas de sílice fundida de grado UV desempeñan un papel vital en muchas aplicaciones ópticas avanzadas. Los ingenieros las utilizan en óptica láser excimer, litografía ultravioleta profunda (DUV) y espectroscopia UV. Estas aplicaciones exigen una alta transmisión por debajo de 340 nm y resistencia a la solarización.

Los discos de cuarzo de grado UV para aplicaciones ópticas de infrarrojos visibles deben cumplir estrictos requisitos de transparencia UV y durabilidad. La sílice fundida de grado UV permanece transparente hasta 190 nm, mientras que el vidrio y el plástico absorben los rayos UV y no pueden utilizarse en estos sistemas. La espectroscopia UV se beneficia de la baja absorbancia de fondo y de las lecturas precisas que proporciona la sílice fundida de gran pureza.

Puntos clave:

La sílice fundida de grado UV es esencial para los láseres de excímeros y la litografía DUV.

Su alta transmisión y baja absorbancia la hacen ideal para la espectroscopia UV.

Sólo las obleas de sílice fundida de gran pureza satisfacen las exigencias de las aplicaciones ópticas UV profundas.

¿Qué diferencias de grado de material definen el disco de cuarzo de grado óptico para aplicaciones Visible-NIR (260-2500 nm)?

Los discos de cuarzo de grado óptico desempeñan un papel vital en las aplicaciones ópticas del visible y el infrarrojo cercano. Estos grados ofrecen una alta transmisión, durabilidad y rentabilidad para una amplia gama de componentes ópticos. Comprender las diferencias entre la sílice fundida de grado óptico y la de grado UV ayuda a los ingenieros a seleccionar las obleas de sílice fundida adecuadas para sus necesidades específicas.

Comparación del rendimiento de transmisión: Grado óptico frente a grado UV en la gama visible-NIR

Las obleas de sílice fundida de grado óptico ofrecen una excelente transmisión en el espectro visible e infrarrojo cercano. En el rango de 260-2500 nm, tanto la sílice fundida de grado óptico como la de grado UV alcanzan una transmisión superior a 92%, lo que las hace prácticamente indistinguibles para la mayoría de las aplicaciones ópticas. La principal diferencia aparece por debajo de 250 nm, donde la sílice fundida de grado UV supera a la de grado óptico debido a la menor cantidad de impurezas metálicas, pero esta ventaja desaparece en las regiones visible e infrarroja cercana.

Los ingenieros suelen elegir obleas de sílice fundida de grado óptico para aplicaciones visibles-NIR porque los mayores niveles de impurezas no afectan al rendimiento en esta gama. Ambas calidades mantienen un alto rendimiento óptico, pero la calidad óptica ofrece una mejor relación coste-rendimiento cuando no se requiere una transmisión de alta resolución. Por ello, el grado óptico es la opción preferida para la mayoría de los componentes de imagen, iluminación y control del haz láser.

Grado | Transmisión (260-2500 nm) | Transmisión (<250nm) | Causalidad/Impacto |

|---|---|---|---|

Grado óptico | >92% | 45-60% | Las altas impurezas limitan el UV profundo, no el visible-NIR |

Grado UV | >92% | >85% | Las bajas impurezas potencian eluv profundo, igual en visible-NIR |

Esta comparación muestra que las obleas de sílice fundida de grado óptico ofrecen el mismo rendimiento óptico que la sílice fundida de grado UV en el rango visible-NIR, lo que las hace ideales para la mayoría de los componentes ópticos.

Análisis coste-rendimiento: Cuando la calidad UV no está justificada

Los discos de cuarzo de calidad óptica para aplicaciones ópticas de infrarrojos visibles y ultravioletas ofrecen un ahorro de costes significativo en comparación con la sílice fundida de calidad ultravioleta. El proceso de fabricación del grado óptico utiliza cuarzo natural, lo que reduce los costes de producción en un 50-65% sin dejar de ofrecer una alta transmisión en las regiones visible y NIR. Para aplicaciones por encima de 280 nm, el precio de la sílice fundida de calidad UV suele ser innecesario.

Muchos componentes ópticos, como las lentes de captura de imágenes y la fibra óptica, no requieren las capacidades de ultravioleta de la sílice fundida de grado ultravioleta. Al seleccionar obleas de sílice fundida de grado óptico, los ingenieros pueden reducir los costes del sistema sin sacrificar el rendimiento óptico. Este enfoque garantiza que los presupuestos se utilicen de forma eficiente, manteniendo al mismo tiempo la calidad necesaria para las aplicaciones visibles-NIR.

Puntos clave:

Las obleas de sílice fundida de grado óptico cuestan mucho menos que la sílice fundida de grado UV.

Ambos grados funcionan igual de bien en el rango visible-NIR.

La elección de la calidad óptica para aplicaciones no UV maximiza el valor.

Este equilibrio entre coste y rendimiento convierte a la calidad óptica en la elección inteligente para la mayoría de ópticas visibles e infrarrojas cercanas.

Equivalencia de las propiedades de los materiales: Comportamiento térmico, mecánico y químico idéntico en todos los grados

Tanto las obleas de sílice fundida de grado óptico como las de grado UV comparten propiedades térmicas, mecánicas y químicas casi idénticas. Su resistencia a las altas temperaturas, al choque térmico y a la mayoría de los productos químicos sigue siendo la misma, y sólo los ácidos fluorhídrico y fosfórico causan daños. Las principales diferencias entre estos grados provienen de la pureza y la fabricación, no de sus propiedades inherentes como material.

Los ingenieros pueden confiar en cualquiera de los dos grados para entornos exigentes, ya que ambos soportan temperaturas continuas de hasta 1000 °C y exposiciones de corta duración de hasta 1200 °C. Su elevada dureza y resistencia a la abrasión garantizan una larga vida útil de los componentes ópticos en entornos industriales y científicos. Esta equivalencia permite a los diseñadores centrarse en el rendimiento óptico y el coste a la hora de elegir entre los distintos grados.

Propiedad | Grado óptico | Grado UV | Causalidad/Impacto |

|---|---|---|---|

Resistencia térmica | Idéntico | Idéntico | Ambas calidades soportan por igual el calor elevado |

Resistencia química | Idéntico | Idéntico | Ambos resisten la mayoría de los productos químicos excepto HF, H₃PO₄ |

Resistencia mecánica | Idéntico | Idéntico | Ambos proporcionan durabilidad y resistencia a la abrasión |

Esta tabla pone de relieve que las obleas de sílice fundida de grado óptico y de grado ultravioleta ofrecen la misma durabilidad y fiabilidad para los componentes ópticos.

Ejemplos de aplicaciones Visible-NIR: Lentes de imagen, fibra óptica, sistemas láser Nd:YAG

Las obleas de sílice fundida de calidad óptica son la base de muchas aplicaciones en el visible y el infrarrojo cercano. Los ingenieros las utilizan en imagen, iluminación y control de haces láser, donde son esenciales una transmisión alta y uniforme, resistencia al choque térmico y compatibilidad con longitudes de onda específicas. Estas obleas también son compatibles con la fibra óptica y los sistemas láser Nd:YAG, ya que ofrecen una alta transmitancia a 1.064 nm, una excelente resistencia al calor y una larga vida útil.

En entornos médicos e industriales, los discos de cuarzo de calidad óptica permiten un rendimiento óptico preciso y un funcionamiento fiable. Su bajo coeficiente de expansión térmica y su alta resistencia al choque térmico los hacen ideales para entornos exigentes. La combinación de durabilidad y claridad óptica garantiza que estos componentes cumplan estrictos requisitos de rendimiento y longevidad.

Puntos clave:

Las obleas de sílice fundida de calidad óptica destacan en la captura de imágenes, la iluminación y el control del haz láser.

La fibra óptica y los sistemas láser Nd:YAG se benefician de una alta transmisión y resistencia al calor.

Estos componentes ofrecen un rendimiento óptico fiable en aplicaciones médicas e industriales.

Esta amplia gama de usos demuestra la versatilidad y el valor de las obleas de sílice fundida de calidad óptica en la óptica visible-NIR.

¿Qué diferencias de grado de material definen el disco de cuarzo de grado IR para aplicaciones infrarrojas (260-3500 nm)?

Los ingenieros seleccionan la sílice fundida de grado ir para aplicaciones que exigen una alta transmisión en la región infrarroja. Este grado de material destaca porque minimiza las pérdidas de absorción causadas por grupos hidroxilo. Comprender las diferencias en los grados de material de los discos de cuarzo uv aplicaciones ópticas infrarrojas visibles ayuda a los usuarios a elegir las mejores obleas de sílice fundida para sus necesidades.

Comparación del contenido de OH: Grado IR (<30 ppm) frente a grado óptico (150-200 ppm)

El contenido de OH desempeña un papel fundamental en el rendimiento de la sílice fundida de grado IR. Las obleas de sílice fundida de grado IR contienen menos de 30 ppm de iones hidroxilo, mientras que la sílice fundida de grado óptico suele tener entre 150 y 200 ppm. El menor contenido de OH en la sílice fundida de grado IR conduce a una mayor transmisión en el rango IR, especialmente entre 2,5 y 4,5 micras.

La diferencia en el contenido de OH afecta directamente a las características de absorción de cada grado. Los altos niveles de OH en las obleas de sílice fundida de grado óptico provocan una absorción significativa en el infrarrojo, lo que reduce su eficacia para aplicaciones IR. La sílice fundida de grado IR, con su bajo contenido en OH, mantiene una transmisión superior y admite sistemas ópticos exigentes.

Grado de cuarzo | Contenido típico de OH | Alcance de la transmisión | Impacto del contenido OH en la transmisión |

|---|---|---|---|

Calidad óptica | 150-400 ppm | Gama UV (185-400 nm) | Mayor absorción en el rango IR |

Grado IR | <20 ppm | Gama IR (2,5-4,5μm) | Transmisión superior en el rango IR |

Esta tabla muestra cómo el contenido de OH determina la idoneidad de cada grado para determinados rangos de longitud de onda.

Mecanismos de absorción infrarroja: Bandas vibracionales del hidroxilo a 2730 nm

Los grupos hidroxilo de la sílice fundida crean fuertes bandas de absorción en el infrarrojo, especialmente cerca de 2730 nm. Estas bandas vibracionales surgen del movimiento de estiramiento de los enlaces OH, que absorben la luz IR y reducen la transmisión. La presencia de estas bandas limita el rendimiento de las obleas de sílice fundida de calidad óptica en la región IR.

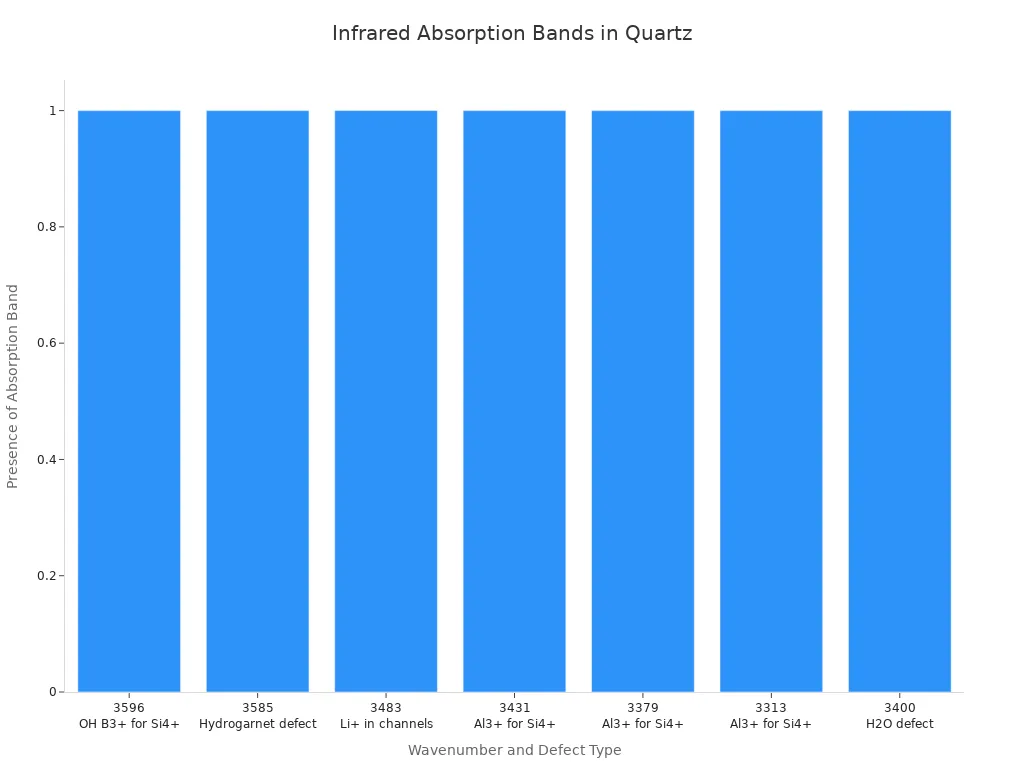

Los investigadores han identificado varias bandas de absorción clave en el cuarzo, cada una de ellas vinculada a defectos estructurales o impurezas específicos. Por ejemplo, las bandas de 3596 cm-1 y 3400 cm-1 están relacionadas con distintos tipos de incorporación de OH, mientras que las bandas de 3431 cm-1 y 3313 cm-1 están asociadas a la sustitución por aluminio. Estas características de absorción explican por qué la sílice fundida de grado ir, con menor contenido en OH, presenta mejores resultados en el infrarrojo.

El gráfico anterior ilustra las principales bandas de absorción que afectan a la transmisión IR en la sílice fundida.

Diferencias en el proceso de fabricación: Fusión por vacío frente a fusión por aire Impacto en la incorporación de OH

En el proceso de fabricación determina el contenido final de OH en sílice fundida de grado ir. La fusión al vacío limita la presencia de vapor de agua y oxígeno, lo que reduce la incorporación de grupos hidroxilo durante la producción. Por el contrario, la fusión por aire o por llama introduce más OH, lo que da lugar a una mayor absorción en la región IR.

Los fabricantes de obleas de sílice fundida de grado ir utilizan la fusión en vacío para conseguir los bajos niveles de OH necesarios para una alta transmisión infrarroja. Este proceso aumenta los costes de producción, pero garantiza que el material cumpla las estrictas normas ópticas. La elección del método de fabricación afecta directamente tanto al rendimiento como al precio del producto final.

Puntos clave:

La fusión al vacío reduce la incorporación de OH en la sílice fundida de grado ir.

La fusión del aire provoca un mayor contenido de OH y una menor transmisión de IR.

El método de fabricación influye tanto en el coste como en la calidad óptica.

Estas diferencias explican por qué se prefiere la sílice fundida de grado IR para aplicaciones IR exigentes.

Ejemplos de aplicaciones IR: Espectroscopia NIR, imágenes SWIR, sensores térmicos

Las obleas de sílice fundida de grado IR admiten una amplia gama de aplicaciones ópticas infrarrojas. Los ingenieros las utilizan en espectroscopia NIR, imágenes SWIR y sensores térmicos por su alta transmisión y baja absorción en la región IR. Estas propiedades hacen que la sílice fundida de grado IR sea ideal para sistemas que requieren mediciones precisas y una pérdida de señal mínima.

Los sensores térmicos se benefician de la sílice fundida de grado ir por sus bajas pérdidas por reflexión y sus rápidos tiempos de enfriamiento. Los discos de cuarzo superan a los de zafiro en estas aplicaciones, ya que reflejan menos calor y permiten que los sensores respondan con rapidez. La combinación de una elevada transmisión de infrarrojos y una gestión térmica eficaz convierte a la sílice fundida de grado ir en el material preferido para diseños de sensores avanzados.

Aplicación | Beneficio material | Impacto en el rendimiento |

|---|---|---|

Espectroscopia NIR | Alta transmisión IR | Mediciones espectrales precisas |

Imágenes SWIR | Baja absorción en IR | Imágenes nítidas, mínima pérdida de señal |

Sensores térmicos | Baja reflexión, enfriamiento rápido | Respuesta mejorada del sensor |

Esta tabla resume cómo la sílice fundida de grado ir permite un rendimiento superior en aplicaciones clave de infrarrojos.

¿Cómo se comparan las calidades de los materiales en toda la gama espectral (UV-Visible-IR)?

Los grados de material de los discos de cuarzo muestran distintos perfiles de transmisión en todo el espectro. Los ingenieros deben comparar las obleas de sílice fundida de grado UV, óptico e IR para seleccionar la mejor opción para sus aplicaciones. Comprender estas diferencias ayuda a los usuarios a elegir el grado adecuado para sus necesidades de rendimiento.

Tabla comparativa de transmisión espectral: Los tres grados 185-3500nm

Cada grado de obleas de sílice fundida presenta unas características de transmisión únicas desde las longitudes de onda ultravioleta a las infrarrojas. La sílice fundida de grado UV mantiene una alta transmisión por debajo de 250 nm, mientras que la de grado óptico destaca en el rango visible y la de grado ir ofrece un rendimiento superior en infrarrojos. Los datos de transmisión muestran que la sílice fundida de grado uv alcanza una transmitancia superior a 85% a 193 nm, la de grado óptico supera los 92% en el espectro visible y la de grado ir mantiene más de 85% a 2800 nm.

Grado | UV (185-250 nm) | Visible (400-700 nm) | IR (2500-3500 nm) | Causalidad/Impacto |

|---|---|---|---|---|

Grado UV | >85% | >90% | 60-75% | Pocas impurezas potencian UV, OH limita IR |

Grado óptico | 45-60% | >92% | 45-55% | Impurezas moderadas, límites OH altos IR |

Grado IR | 35-50% | >90% | >85% | El OH bajo potencia el IR, los metales altos limitan el UV |

Esta tabla muestra cómo cada grado optimiza la transmisión para rangos de longitud de onda específicos.

Análisis de compromiso de rendimiento: Optimización de la longitud de onda frente al coste

Seleccionar el grado adecuado implica encontrar un equilibrio entre rendimiento y coste para el espectro previsto. Las obleas de sílice fundida de calidad UV ofrecen una alta transmisión sin igual en el ultravioleta profundo, pero su elevado coste sólo se justifica para aplicaciones por debajo de 250 nm. El grado óptico ofrece una excelente relación calidad-precio para componentes visibles e infrarrojos cercanos, mientras que la sílice fundida de grado ir ofrece los mejores resultados para ventanas y lentes infrarrojas.

Los ingenieros suelen elegir el grado óptico para la mayoría de las lentes y ventanas porque es igual a la sílice fundida de grado uv en el rango visible a un precio inferior. Para aplicaciones infrarrojas, la sílice fundida de grado ir garantiza una alta transmisión y una absorción mínima, lo que la convierte en la opción preferida. El ahorro de costes aumenta cuando los usuarios adaptan el grado a la longitud de onda de funcionamiento.

Puntos clave:

La sílice fundida de grado UV es esencial para la UV profunda.

El grado óptico ofrece alta transmisión y valor para visible-NIR.

La sílice fundida de grado IR es óptima para aplicaciones de infrarrojos.

Elegir el grado correcto maximiza el rendimiento y la eficiencia presupuestaria.

Tabla de equivalencias de propiedades de materiales: Especificaciones no ópticas Idénticas

Todos los grados de obleas de sílice fundida comparten propiedades no ópticas similares. La resistencia térmica, la solidez mecánica y la durabilidad química son las mismas en la sílice fundida de grado UV, óptico e IR. Estas especificaciones garantizan un rendimiento fiable de los componentes en entornos exigentes.

Propiedad | Grado UV | Grado óptico | Grado IR | Causalidad/Impacto |

|---|---|---|---|---|

Resistencia térmica | Idéntico | Idéntico | Idéntico | Todos los grados soportan altas temperaturas |

Resistencia mecánica | Idéntico | Idéntico | Idéntico | Duradero para todas las aplicaciones |

Durabilidad química | Idéntico | Idéntico | Idéntico | Resistente excepto a HF, H₃PO₄ |

Los ingenieros pueden seleccionar cualquier grado para los componentes que requieren durabilidad, centrándose en la transmisión y el coste para las decisiones finales.

Los grados de material de los discos de cuarzo muestran claras diferencias en pureza y transmisión. El grado UV es adecuado para la óptica del ultravioleta profundo porque tiene pocas impurezas metálicas. El grado óptico es el más adecuado para aplicaciones en el visible y el infrarrojo cercano, ya que ofrece una alta transmisión y ahorro de costes. El grado IR ofrece un rendimiento superior en infrarrojos gracias a su bajo contenido en hidroxilos.

Consejo: Seleccione el grado UV para longitudes de onda inferiores a 250 nm, el grado óptico para 260-2300 nm y el grado IR para aplicaciones superiores a 2500 nm. La adecuación del grado a la gama de longitudes de onda garantiza un rendimiento y una eficiencia presupuestaria óptimos.

PREGUNTAS FRECUENTES

¿Cuál es la principal diferencia entre las calidades de sílice fundida UV, óptica e IR?

Cada grado transmite mejor la luz en un rango específico de longitudes de onda. El grado UV es adecuado para el ultravioleta profundo, el grado óptico es adecuado para el visible y el infrarrojo cercano, y el grado IR destaca en el infrarrojo. Elegir el grado adecuado garantiza las mejores especificaciones ópticas para cualquier aplicación.

¿Cómo afectan las impurezas a las calidades de la sílice fundida?

Las impurezas, como los metales y los grupos hidroxilo, reducen la transmisión en determinados rangos. Un alto contenido en metales bloquea la luz ultravioleta, mientras que un alto contenido en hidroxilos absorbe los infrarrojos. Los fabricantes controlan estas impurezas para adaptar cada grado a su gama ideal de longitudes de onda.

Tipo de impureza | Gama afectada | Impacto en la transmisión |

|---|---|---|

Metales | UV | Reduce la transmisión de rayos UV |

Hidroxilo (OH) | IR | Reduce la transmisión de infrarrojos |

¿Puede un grado de sílice fundida cubrir todas las aplicaciones ópticas?

No existe ningún grado que ofrezca el máximo rendimiento en todo el espectro. El grado UV pierde eficacia en el IR, y el grado IR no transmite bien el UV profundo. Los ingenieros seleccionan los grados de sílice fundida en función de las necesidades de longitud de onda de la aplicación.

¿Por qué son importantes las especificaciones ópticas a la hora de elegir un disco de cuarzo?

Las especificaciones ópticas definen la cantidad de luz que pasa y la transparencia del material. Ayudan a los ingenieros a adaptar el grado adecuado a los requisitos del sistema. Una selección adecuada mejora el rendimiento y reduce los costes.

¿Son diferentes las propiedades térmicas y mecánicas entre los distintos grados?

Todos los grados comparten propiedades térmicas y mecánicas similares. Resisten igual de bien el calor y las tensiones físicas. Las principales diferencias solo aparecen en su rendimiento óptico.

Consejo: Adapte siempre el grado a la gama de longitudes de onda para obtener los mejores resultados.