La temperatura máxima de los tubos de cuarzo resistentes al calor depende de las condiciones de funcionamiento. La mayoría de los tubos de vidrio de cuarzo funcionan de forma estable a 1200°C durante largos periodos. Las exposiciones de corta duración pueden alcanzar 1450-1600°C, pero la degradación estructural comienza si las temperaturas suben o duran demasiado. La carga mecánica, la contaminación y el contenido de OH pueden reducir la temperatura máxima. La tabla siguiente muestra los umbrales típicos:

Temperatura | Descripción |

|---|---|

Hasta 1800°C | Temperatura máxima sin degradación estructural |

1200°C | Funcionamiento estable durante largos periodos |

1450 a 1600°C | Temperaturas brevemente soportables |

1750°C | Punto de fusión del vidrio de cuarzo |

Principales conclusiones

Los tubos de cuarzo resistentes al calor pueden funcionar continuamente a temperaturas de hasta 1.200 °C sin perder su integridad estructural.

La exposición a corto plazo permite a los tubos de cuarzo soportar temperaturas de entre 1300°C y 1400°C, pero sólo durante breves periodos.

La contaminación y el alto contenido de hidroxilo pueden reducir significativamente la temperatura de funcionamiento segura de los tubos de cuarzo.

La orientación y el soporte adecuados del tubo son cruciales; los tubos verticales pueden soportar temperaturas más altas que los horizontales.

Los ingenieros deben documentar todas las especificaciones y resultados de las pruebas para garantizar la fiabilidad de los tubos de cuarzo en aplicaciones de alta temperatura.

¿Qué umbral de temperatura define la pérdida de integridad estructural en los tubos de vidrio de cuarzo resistentes al calor?

Definición de la degradación estructural: Umbrales de viscosidad y criterios de deformación

Integridad estructural en tubos de cuarzo de alta temperatura depende de cómo responda el material al calor con el paso del tiempo. Cuando el vidrio de cuarzo se calienta, su viscosidad disminuye. La viscosidad mide la resistencia del material a fluir. A altas temperaturas, el cuarzo se vuelve menos rígido y puede deformarse bajo su propio peso o cargas externas. Los ingenieros utilizan umbrales de viscosidad para predecir cuándo se producirá la deformación. En la mayoría de las aplicaciones de alta temperatura, los tubos de cuarzo deben mantener una viscosidad superior a 10¹² Poise para evitar que se comben o se doblen.

La degradación estructural comienza cuando el tubo muestra cambios visibles en su forma. Estos cambios incluyen hundimiento, estiramiento o pérdida de redondez. Si la temperatura supera el límite de seguridad, el tubo puede perder su capacidad para soportar cargas. La temperatura máxima del tubo de cuarzo resistente al calor para uso continuo suele ser de 1200°C. Los tubos expuestos a temperaturas más altas durante periodos cortos pueden soportar hasta 1300-1400°C, pero sólo si la exposición dura menos de 30 minutos. Superar estos límites puede causar una deformación permanente, haciendo que el tubo no pueda seguir utilizándose.

Consejo: Compruebe siempre si hay signos de pandeo o distorsión después de procesos a alta temperatura. La detección precoz ayuda a mantener la calidad y la seguridad.

Límites de temperatura continuos frente a límites de temperatura a corto plazo: Relaciones tiempo-temperatura

El rendimiento de los tubos de cuarzo varía en función del tiempo que estén expuestos a altas temperaturas. El uso continuo significa que el tubo permanece a alta temperatura durante semanas o meses. La exposición de corta duración se refiere a breves picos de temperatura durante determinados procesos. La temperatura máxima que pueden soportar los tubos de cuarzo depende tanto de la duración como del entorno.

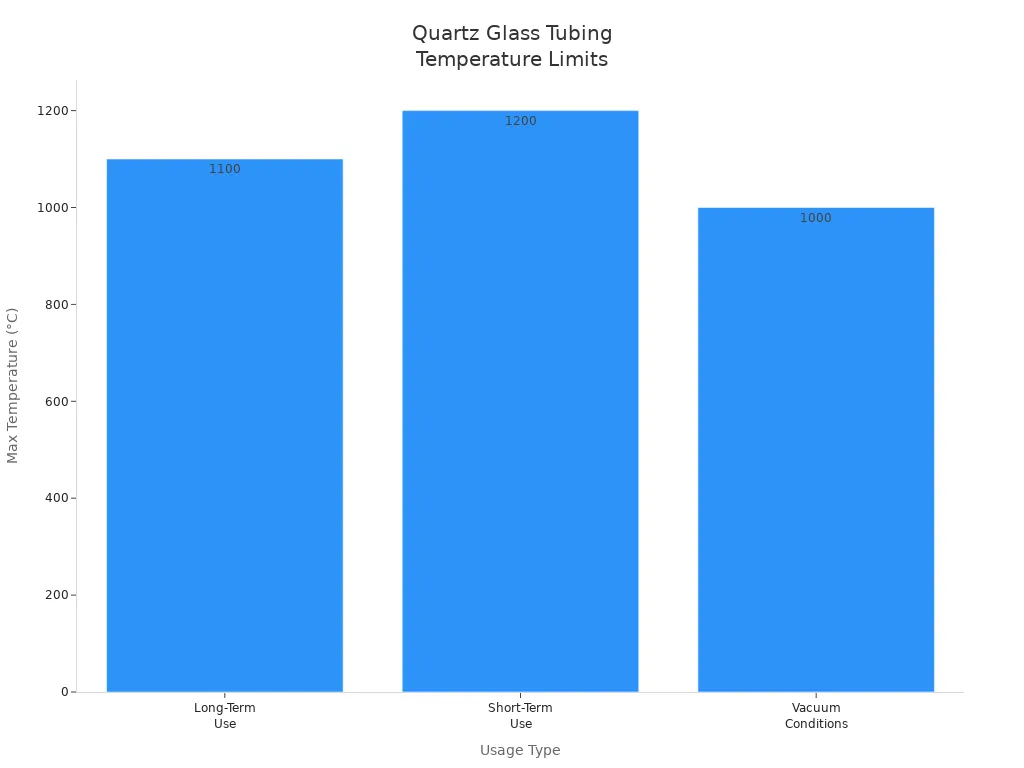

La siguiente tabla muestra cómo afecta el tipo de uso a los límites de temperatura de los tubos de cuarzo:

Tipo de uso | Temperatura máxima | Notas |

|---|---|---|

Uso a largo plazo | 1100°C | Adecuado para aplicaciones constantes a altas temperaturas. |

Uso a corto plazo | 1200°C | Ideal para procesos con picos temporales de temperatura. |

Condiciones de vacío | 1000°C | La potencia máxima disminuye debido a la reducción de la presión que afecta a la estabilidad. |

Los tubos de cuarzo de alta temperatura en entornos de vacío tienen límites de temperatura más bajos. La presión reducida hace que el material sea más propenso a deformarse. Unas prácticas de calentamiento adecuadas ayudan a evitar el choque térmico y prolongan la vida útil del tubo. Superar los 1.200 °C puede provocar deformaciones que comprometen la integridad estructural.

Relación entre el punto de reblandecimiento (1665 °C) y los límites prácticos de funcionamiento (1200 °C)

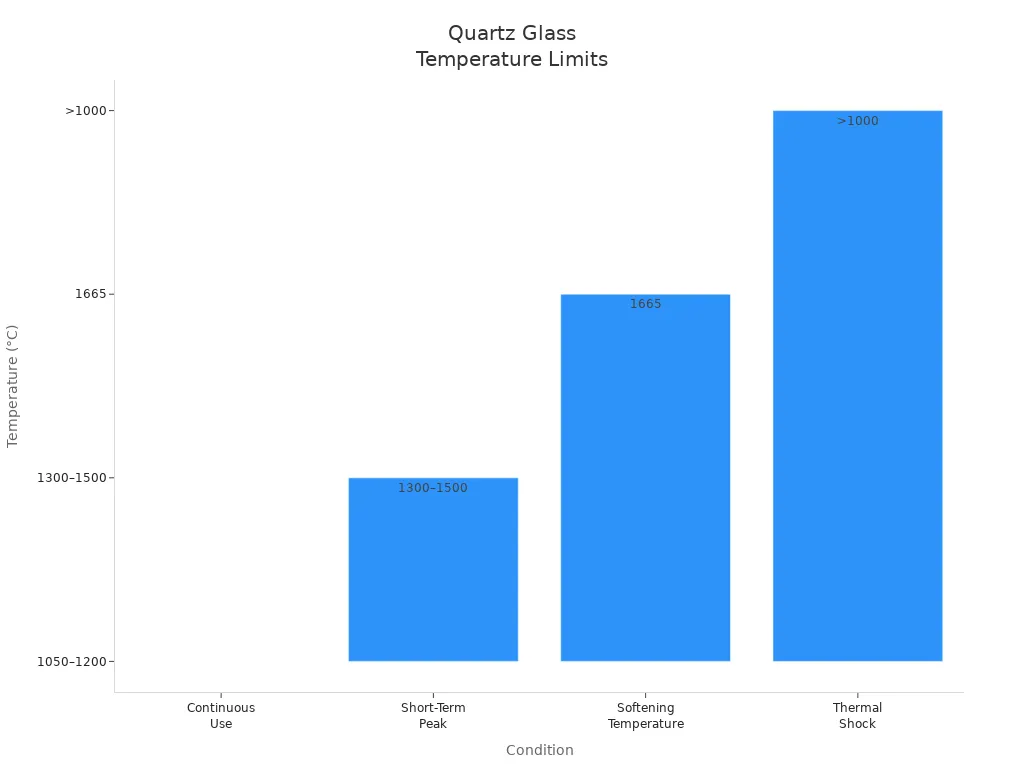

El punto de reblandecimiento del vidrio de cuarzo marca la temperatura a la que el material pierde rigidez y empieza a fluir. Para el cuarzo de gran pureza, este punto se sitúa en torno a los 1665°C. Sin embargo, el límite de temperatura de los tubos de cuarzo para uso práctico es mucho más bajo. La mayoría de las aplicaciones de resistencia a altas temperaturas requieren que el tubo se mantenga por debajo de 1200°C para un funcionamiento continuo. Los picos a corto plazo pueden alcanzar los 1300-1500°C, pero sólo durante breves periodos.

La tabla siguiente compara el punto de reblandecimiento y los límites prácticos de funcionamiento:

Condición | Temperatura (°C) | Descripción |

|---|---|---|

Uso continuo | 1050-1200 | Estable, sin deformaciones |

Pico a corto plazo | 1300-1500 | Mantiene la integridad, se ablanda cerca de la parte superior |

Temperatura de ablandamiento | 1665 | Pérdida de rigidez, fluidez |

Choque térmico | >1000 | Intacto tras el ciclado rápido |

La diferencia entre el punto de reblandecimiento y la temperatura máxima permitida para el funcionamiento es importante. El punto de reblandecimiento indica cuándo empezará a fluir el material. El límite práctico de funcionamiento es la temperatura más alta a la que el tubo mantiene su forma y soporta cargas durante los procesos a alta temperatura. Los tubos de cuarzo de alta temperatura deben permanecer por debajo de este límite para garantizar la estabilidad térmica y mantener la calidad.

Tabla resumen: Límites de temperatura para tubos de cuarzo en diferentes condiciones

El límite de temperatura de los tubos de cuarzo cambia en función de la orientación, la pureza y el entorno. La tabla siguiente resume estos límites:

Condición | Temperatura límite |

|---|---|

Atmosférico (1 atm) | Hasta 1200°C |

Vacío | Hasta 1000°C |

Factores clave | Prácticas de calefacción, entorno gaseoso, ciclos térmicos |

Aplicaciones | Procesado de semiconductores, síntesis de materiales, tratamiento térmico |

Limitaciones | Menos duradero bajo ciclos térmicos repetidos |

El cuarzo de gran pureza proporciona un mejor rendimiento en aplicaciones de alta temperatura. Los tubos en posición horizontal o en entornos contaminados pueden necesitar límites de temperatura más bajos. Los ingenieros deben tener en cuenta todos los factores para garantizar el mejor rendimiento de los tubos de cuarzo y mantener la integridad estructural.

¿Cómo reduce la temperatura máxima admisible la configuración de carga?

Cálculo de la reducción de temperatura para orientaciones de tubo horizontales frente a verticales

Los ingenieros se preguntan a menudo qué factores reducen la temperatura máxima admisible para los tubos de cuarzo de alta temperatura. La orientación de los tubos desempeña un papel importante. Los tubos verticales soportan mejor su propio peso, por lo que mantienen la estabilidad térmica a temperaturas más elevadas. Los tubos horizontales experimentan más tensión de flexión, lo que reduce el límite de temperatura de los tubos de cuarzo. Por ejemplo, los tubos verticales en aplicaciones de alta temperatura pueden funcionar con seguridad a 1200°C, mientras que los tubos horizontales pueden necesitar reducir su límite entre 50 y 100°C. Esta diferencia ayuda a evitar el pandeo y preserva la calidad en entornos exigentes.

Nota: Compruebe siempre la orientación del tubo antes de fijar los límites de temperatura. Los tubos horizontales requieren una inspección más frecuente para detectar deformaciones.

Impacto del diámetro y el espesor de pared en los límites de temperatura de carga

El tamaño del tubo también afecta al rendimiento del tubo de cuarzo de alta temperatura. Los diámetros más grandes y las paredes más finas aumentan el riesgo de deformación. Los tubos de cuarzo de gran pureza con paredes gruesas resisten mejor la flexión, lo que mejora la resistencia a las altas temperaturas. En las aplicaciones de alta temperatura, los ingenieros seleccionan las dimensiones de los tubos en función de las cargas previstas y la longitud del tramo.

Optimización del intervalo de soporte para maximizar la temperatura de funcionamiento

La optimización de la distancia entre soportes aumenta la resistencia al choque térmico y prolonga la vida útil. Los tramos sin soporte más cortos permiten que los tubos de cuarzo de alta temperatura funcionen más cerca de su temperatura máxima permitida. Los ingenieros colocan los soportes a intervalos regulares para reducir la flexión y mantener los límites térmicos. En aplicaciones de alta temperatura, una separación adecuada de los soportes garantiza que los tubos conserven su forma y calidad. Los tubos de cuarzo de alta temperatura con soporte optimizado muestran una mayor resistencia al choque térmico y mantienen su rendimiento a lo largo del tiempo.

Consejo: Utilice soportes frecuentes para los tubos horizontales a fin de maximizar la resistencia a las altas temperaturas y evitar el pandeo.

¿Qué factores de contaminación reducen la temperatura máxima antes de que se produzca la desvitrificación?

Contaminación por metales alcalinos: Cuantificación de la reducción de la temperatura frente a la concentración

La contaminación por metales alcalinos tiene un fuerte efecto sobre la temperatura máxima de los tubos de cuarzo resistentes al calor. Incluso pequeñas cantidades de metales alcalinos, como el sodio o el potasio, pueden reducir el límite de temperatura de los tubos de cuarzo al favorecer la desvitrificación. En el cuarzo de alta temperatura, los metales alcalinos actúan como catalizadores para la formación de fases cristalinas como la cristobalita. Este proceso puede comenzar a temperaturas cientos de grados más bajas que en el cuarzo puro. La contaminación de la superficie por compuestos alcalinos, sales o vapores acelera la desvitrificación y reduce la temperatura máxima admisible para aplicaciones de alta temperatura. La manipulación del cuarzo con las manos desnudas puede depositar suficiente álcali para provocar una desvitrificación visible, lo que acorta la vida útil y reduce la calidad.

Temperatura de inicio de la desvitrificación: Cómo las impurezas catalizan la cristalización

Las impurezas del cuarzo de alta temperatura, incluidos los grupos hidroxilo y los elementos metálicos, disminuyen la estabilidad térmica del material. Estas impurezas aumentan el riesgo de cristalización superficial, especialmente en zonas expuestas a altas temperaturas locales. La tabla siguiente muestra cómo afectan los contaminantes específicos al inicio de la desvitrificación:

Descripción de las pruebas | Implicación en la cristalización y la desvitrificación |

|---|---|

El SrCO3 como agente desvitrificante reduce la temperatura del proceso para la cristalización. | Las impurezas pueden catalizar la cristalización reduciendo la temperatura necesaria para los cambios de fase. |

Mayores concentraciones de SrCO3 reducen la temperatura de inicio de la desvitrificación. | La distribución de las impurezas afecta directamente al momento en que comienza la desvitrificación. |

Las bajas concentraciones de SrCO3 favorecen la formación de α-cuarzo. | Las impurezas específicas pueden favorecer ciertas fases cristalinas en detrimento de otras. |

Con el tiempo, la desvitrificación reduce la transmisión de infrarrojos y la vida útil del cuarzo de alta temperatura. Este efecto se acentúa en las aplicaciones de alta temperatura, donde el límite de temperatura de los tubos de cuarzo es crítico.

Identificación de las fuentes de contaminación que reducen la temperatura de funcionamiento segura

Varias fuentes comunes de contaminación pueden reducir la temperatura de funcionamiento seguro del cuarzo de alta temperatura. Entre ellas se incluyen:

Soluciones alcalinas, sales o vapores presentes en el ambiente.

Manipulación del cuarzo con las manos desnudas, lo que deja depósitos alcalinos procedentes de la transpiración.

Gotas de agua que recogen contaminantes del aire, causando manchas desvitrificadas.

Contaminación superficial que inicia la nucleación de la cristobalita.

Para mantener la resistencia al choque térmico y los límites térmicos, los ingenieros deben evitar el contacto directo con el cuarzo y utilizar guantes limpios. Los tubos de cuarzo de alta temperatura en entornos contaminados pueden requerir un límite inferior de temperatura de los tubos de cuarzo para evitar la desvitrificación. Para aplicaciones de alta temperatura, documentación como ASTM C598 e ISO 12123 ayuda a verificar la temperatura máxima permitida y garantiza una calidad constante.

Nota: Una manipulación adecuada y una inspección periódica ayudan a preservar la resistencia a los choques térmicos y a prolongar la vida útil de los tubos de cuarzo de alta temperatura.

¿Cómo afecta el contenido de OH en el vidrio de cuarzo al rendimiento máximo a altas temperaturas?

Low-OH (<30 ppm) vs. High-OH (150-200 ppm): Comparación del rendimiento a temperatura

El tubo de vidrio de cuarzo con bajo contenido en hidroxilo presenta una excelente resistencia al calor en aplicaciones de alta temperatura. Los tubos con menos de 30 ppm de contenido de hidroxilo mantienen la integridad estructural a temperaturas más elevadas. El cuarzo de alta temperatura con alto contenido en OH, entre 150 y 200 ppm, experimenta una durabilidad reducida. Por cada 10 ppm de aumento en el contenido de hidroxilo, la temperatura de uso a largo plazo desciende unos 20°C. El cuarzo con bajo contenido en OH soporta una temperatura máxima de funcionamiento cercana a los 1200°C, mientras que el cuarzo con alto contenido en OH suele requerir un funcionamiento por debajo de los 1100°C. Esta diferencia afecta a la calidad y la vida útil en aplicaciones de alta temperatura.

Mecanismos de reducción de la viscosidad: Cómo los grupos OH debilitan los enlaces Si-O-Si

Los grupos OH del cuarzo de alta temperatura modifican el comportamiento del material bajo el calor. La presencia de inclusiones de hidroxilo y agua provoca hidrólisis de los enlaces Si-O. Este proceso reduce la viscosidad y debilita la estructura del vidrio. El aluminio en el cuarzo puede estabilizar los grupos OH e influir en la formación de vacantes de oxígeno. Cuando hay aluminio, aumenta la entalpía de hidrólisis, lo que ralentiza la reacción y afecta a la formación de grupos OH. Estos cambios hacen que el cuarzo de alta temperatura sea menos resistente a la deformación, especialmente en aplicaciones exigentes de alta temperatura.

Los ingenieros deben supervisar el contenido de OH para mantener la calidad y evitar el fallo prematuro de los tubos.

El contenido de grupos OH influye en la viscosidad y la formación de cristobalitay la evolución de las burbujas durante el tratamiento térmico.

Un mayor contenido de OH provoca un mayor crecimiento de las burbujas y modifica la cinética de formación de la cristobalita.

La nucleación de nuevas burbujas predomina al principio del tratamiento térmico, mientras que el crecimiento y la coalescencia de las burbujas se producen más tarde.

Selección del contenido de OH en función de los requisitos de temperatura máxima de funcionamiento

Elegir el contenido de OH adecuado garantiza que el cuarzo de alta temperatura funcione bien en aplicaciones de alta temperatura. El cuarzo bajo en hidroxilo, con un contenido de OH inferior a 5 ppm, absorbe menos energía en el rango UV y favorece mayores índices de supervivencia. La tabla siguiente muestra recomendaciones para seleccionar el contenido de OH:

| Tipo de impureza --- Impacto en las tasas de supervivencia de los tubos de cuarzo --- Recomendación | Contenido de hidroxilo (OH-) --- Absorbe energía en el rango UV, afectando a la generación de portadores. --- Utilizar cuarzo con bajo contenido en hidroxilo (OH- < 5 ppm).

La selección de tubos de vidrio de cuarzo con bajo contenido en OH mejora la calidad y prolonga la vida útil en aplicaciones de alta temperatura. Los ingenieros deben especificar el contenido de OH en función de la temperatura máxima de funcionamiento requerida y de las condiciones de proceso previstas.

¿Qué normas de calidad validan las especificaciones de temperatura máxima de los tubos de cuarzo termorresistentes?

Normas de ensayo esenciales para validar las declaraciones de temperatura máxima

Fabricantes e ingenieros se basan en normas estrictas para confirmar la temperatura máxima que pueden soportar los tubos de cuarzo de alta temperatura. Estas normas ayudan a garantizar que cada tubo cumple el rendimiento esperado en entornos exigentes. Los métodos de ensayo más reconocidos incluyen:

ASTM C598: Mide los puntos de reblandecimiento y recocido del vidrio. Esta prueba muestra cuándo el vidrio de cuarzo empieza a perder su forma en condiciones de alta temperatura.

ISO 12123: Establece los requisitos de pureza del vidrio de cuarzo, que es importante para mantener la resistencia a las altas temperaturas.

ISO 7991: Comprueba la dilatación térmica del tubo de cuarzo, ayudando a predecir cómo reaccionará el tubo a los cambios de temperatura.

ASTM C1525: Evalúa la resistencia a la desvitrificación, que es crítica para el uso a largo plazo en entornos de alta temperatura.

Estas normas proporcionan un marco claro para verificar la calidad y fiabilidad de los tubos de cuarzo en aplicaciones de alta temperatura.

Interpretación de los datos de viscosidad-temperatura para predecir la vida útil

Comprender cómo la viscosidad cambia con la temperatura es clave para predecir cuánto durarán los tubos de vidrio de cuarzo a alta temperatura. La viscosidad describe la facilidad con la que fluye el vidrio. A medida que aumenta la temperatura, la viscosidad disminuye, lo que aumenta la probabilidad de que el tubo se deforme. Los ingenieros utilizan el siguiente método:

Estudian la curva viscosidad-temperatura para el material de cuarzo específico.

Buscan la temperatura en la que la viscosidad se mantiene lo suficientemente alta como para evitar el hundimiento.

Utilizan leyes como las de Arrhenius o VFT para modelizar cómo cambia la viscosidad en diferentes puntos de alta temperatura.

Este método ayuda a los ingenieros a establecer límites de funcionamiento seguros y estimar la vida útil de los tubos de cuarzo en entornos de alta temperatura.

Protocolos de envejecimiento acelerado: Verificación de la capacidad de funcionamiento continuo a 1200°C

Los ensayos de envejecimiento acelerado desempeñan un papel fundamental a la hora de confirmar que los tubos de cuarzo pueden soportar 1200 °C durante largos periodos. En estas pruebas, los ingenieros exponen los tubos a condiciones de alta temperatura durante cientos o miles de horas. Observan cualquier signo de deformación, hundimiento o desvitrificación. Los tubos que superan estas pruebas muestran un cambio de forma inferior a 0,5%, lo que demuestra su capacidad para mantener la integridad estructural. Estos protocolos ayudan a los usuarios a confiar en que los tubos funcionarán de forma fiable en aplicaciones reales de alta temperatura.

Consejo: Solicite siempre documentación de los resultados de las pruebas y certificaciones cuando especifique tubos de cuarzo para altas temperaturas. Esto garantiza que el producto cumple las estrictas normas de calidad.

¿Cómo deben calcular los ingenieros la temperatura máxima de funcionamiento seguro para aplicaciones específicas?

Metodología paso a paso para el cálculo del límite de temperatura específico de la aplicación

Los ingenieros determinan la temperatura máxima de funcionamiento segura para los tubos de vidrio de cuarzo de alta temperatura siguiendo un planteamiento sistemático. En primer lugar, identifican la aplicación prevista y la vida útil esperada. A continuación, seleccionan la orientación, el diámetro y el grosor de pared correctos del tubo. A continuación, buscan posibles fuentes de contaminación y evalúan la pureza y el contenido de OH del cuarzo. Una vez recopilada esta información, los ingenieros consultan las curvas de viscosidad-temperatura para determinar la temperatura a la que el tubo mantiene su integridad estructural. Aplican factores de reducción por orientación horizontal, diámetros grandes o cargas adicionales. Por último, comparan el límite calculado con los valores recomendados por el fabricante y las normas del sector.

Proceso paso a paso:

Definir la aplicación y la vida útil requerida.

Seleccione la geometría y la orientación del tubo.

Evaluar los riesgos de contaminación y la pureza del material.

Revisar los datos de viscosidad-temperatura.

Aplique la reducción de potencia en función de la carga, la orientación y la contaminación.

Confirme el límite calculado con las normas y los datos del fabricante.

Incorporación de márgenes de seguridad: Equilibrio entre la temperatura y la vida útil prevista

Los márgenes de seguridad ayudan a los ingenieros a equilibrar el rendimiento a alta temperatura y la longevidad de los tubos. Fijan la temperatura de servicio continuo por debajo del máximo absoluto para evitar fallos prematuros. La siguiente tabla muestra los valores recomendados:

Propiedad | Valor/Rango | Condición |

|---|---|---|

Temperatura de servicio continuo (°C) | 1050-1200 | Funcionamiento 24h |

Pico a corto plazo (°C) | 1300-1400 | ≤2h |

Choque térmico ΔT (°C) | 200-250 | exposición repentina |

Ignorar estos límites puede acortar la vida útil de los tubos de cuarzo. Los ingenieros también:

Definir los límites de servicio continuo y los umbrales de choque térmico.

Controlar las tasas de rampa y documentar los umbrales de ΔT.

Incluir en los manuales los ciclos de cocción y los índices de enfriamiento.

Diseñar accesorios para la expansión y el alivio de la tensión.

Siguiendo estos pasos, los ingenieros prolongan la vida útil y mantienen la calidad de los tubos de cuarzo para altas temperaturas.

Requisitos de documentación al especificar la temperatura máxima de funcionamiento

Los ingenieros deben llevar registros detallados cuando especifican la temperatura máxima de funcionamiento. Documentan la geometría seleccionada del tubo, la orientación y las condiciones de carga. Hacen referencia a normas como ASTM C598, ISO 12123 e ISO 7991. Los datos de apoyo incluyen curvas de viscosidad-temperatura, certificados de pureza y resultados de pruebas de envejecimiento acelerado. Los ingenieros también registran los cálculos de reducción de potencia y los márgenes de seguridad utilizados. Esta documentación garantiza la trazabilidad y ayuda a verificar que el tubo funcionará de forma fiable en aplicaciones de alta temperatura.

Consejo: Incluya siempre los resultados de las pruebas, las normas de referencia y las notas de cálculo en los archivos del proyecto. Esta práctica facilita el control de calidad y la resolución de problemas en el futuro.

Los tubos de cuarzo resistentes al calor soportan un uso continuo a altas temperaturas de hasta 1.200°C. La exposición a corto plazo permite el funcionamiento a temperaturas cercanas a los 1.300 °C. El rendimiento a altas temperaturas en el mundo real depende de la carga, la contaminación, el contenido de OH y la geometría del tubo. Los ingenieros deben consultar siempre las normas y los datos del fabricante antes de establecer límites de alta temperatura.

Para obtener los mejores resultados, mantenga los tubos de alta temperatura en entornos limpios y vigile que no presenten signos de deformación. Las aplicaciones de alta temperatura requieren una selección cuidadosa para garantizar la calidad a largo plazo.

Lista de comprobación de referencia rápida para tubos de cuarzo de alta temperatura:

Confirmar el límite continuo de alta temperatura (1.100-1.200°C)

Comprobar el límite de alta temperatura a corto plazo (hasta 1.300°C)

Evaluar la carga y la orientación del tubo para su uso a altas temperaturas

Revisar los riesgos de contaminación en entornos de alta temperatura

Especificar el contenido de OH para la estabilidad a altas temperaturas

Consulte las normas para aplicaciones de alta temperatura

PREGUNTAS FRECUENTES

¿Cuál es la temperatura máxima de funcionamiento continuo de los tubos de vidrio de cuarzo?

Los tubos de vidrio de cuarzo pueden funcionar continuamente a temperaturas de hasta 1200°C. Este límite ayuda a evitar la deformación y garantiza que el tubo mantenga su forma durante un uso prolongado.

¿Qué ocurre si los tubos de cuarzo superan su temperatura máxima?

Si el tubo supera su temperatura máxima, puede combarse, perder su forma o incluso agrietarse. Estos cambios reducen la vida útil del tubo y pueden afectar a la calidad del proceso.

¿Qué factores pueden reducir la temperatura de funcionamiento segura de los tubos de cuarzo?

La contaminación, el alto contenido de hidroxilo, la orientación del tubo y las cargas pesadas pueden reducir la temperatura de funcionamiento segura. Los entornos limpios y un soporte adecuado ayudan a mantener el rendimiento.

¿Qué documentación deben conservar los ingenieros al especificar la temperatura máxima?

Los ingenieros deben llevar un registro de la geometría de los tubos, su orientación, las condiciones de carga, los resultados de las pruebas y las normas utilizadas. Esta documentación ayuda a verificar que el tubo funcionará como se espera.

¿Qué normas confirman la calidad de los tubos de cuarzo termorresistentes?

Normas como ASTM C598 e ISO 12123 confirman el punto de reblandecimiento y la pureza del tubo. Estas pruebas garantizan que el tubo cumple estrictos requisitos de calidad para su uso a altas temperaturas.