- Início

- /

- Tipos

- /

- Tubo de quartzo

- /

- Quartzo industrial opaco com dispersão de luz...

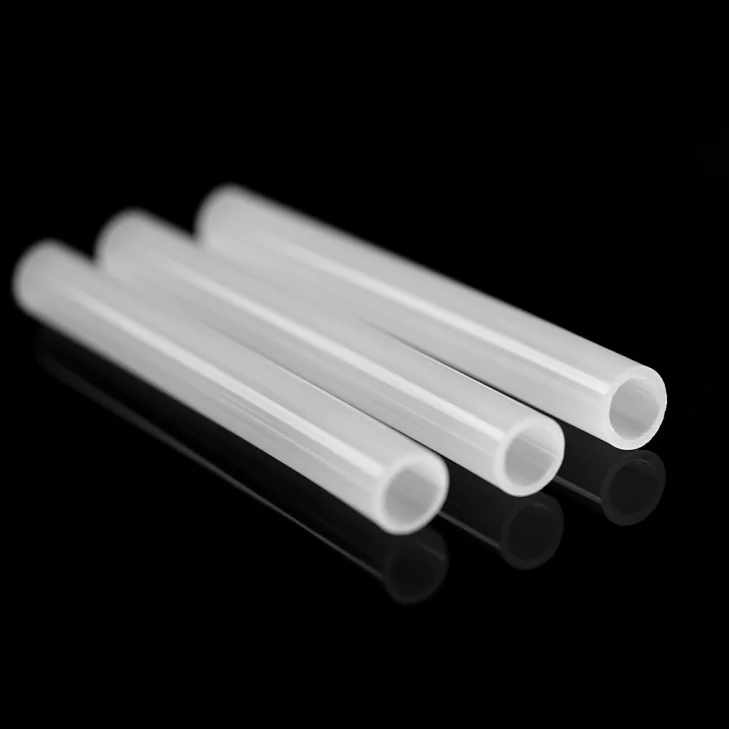

Tubo de quartzo opaco industrial de dispersão de luz aberto em ambas as extremidades para unidades de aquecimento-TOQUARTZ®.

Principais características do tubo de quartzo opaco aberto em ambas as extremidades

Os tubos de quartzo opaco TOQUARTZ® com extremidades abertas apresentam propriedades materiais excepcionais que garantem um desempenho confiável em aplicações industriais exigentes. A aparência branca leitosa é obtida por meio de processos de fabricação controlados, oferecendo ótima difusão de luz e mantendo os benefícios inerentes à sílica fundida de alta pureza.

Propriedades térmicas

- Temperatura máxima de operação contínua: 1100-1200°C

- Temperatura máxima de curto prazo: 1450°C

- Baixo coeficiente de expansão térmica: 5,5×10-⁷ /°C

- Alta resistência a choques térmicos

Propriedades químicas

- Alta pureza: ≥99,98% SiO₂

- Excelente resistência à maioria dos ácidos e produtos químicos

- Resistência a ácidos: 30 vezes maior que a cerâmica, 150 vezes maior que o aço inoxidável

- Inerte à maioria dos gases e líquidos em altas temperaturas

Propriedades ópticas

- Difusão ideal da radiação infravermelha (comprimento de onda de 5-15 μm)

- Transmissão de luz visível: >93%

- Transmissão de luz UV a 185nm: >85%

- Propriedades ópticas estáveis em altas temperaturas

- Alta pureza: ≥99,98% SiO₂

- Temperatura máxima de curto prazo: 1450°C

- Transmissão de luz visível: >93%

Especificações técnicas e tamanhos do tubo de quartzo fosco aberto em ambas as extremidades

Os tubos de quartzo opaco TOQUARTZ® estão disponíveis em uma ampla gama de dimensões para atender a diversos requisitos industriais. Todas as especificações podem ser personalizadas de acordo com as necessidades de seu projeto.

Especificações técnicas

| Propriedade | Especificação |

| Material | Sílica fundida (SiO₂) |

| Pureza | 99.98% |

| Densidade | 2,2 g/cm³ |

| Dureza de Mohs | 6.6 |

| Ponto de fusão | 1732°C |

| Temperatura operacional contínua | 1100°C |

| Temperatura máxima de curto prazo | 1450°C |

| Transmissão de luz visível | ≥93% |

| Transmissão de UV (185nm) | ≥85% |

| Resistividade elétrica | 10.000 vezes maior do que o vidro padrão |

| Ponto de recozimento | 1180°C |

| Ponto de amolecimento | 1630°C |

| Ponto crítico | 1100°C |

Gráficos de dimensão

| Modelo | Diâmetro externo (mm) | Diâmetro interno (mm) | Comprimento (mm) | Pureza |

| AT-SY-MSG1001 | 1 | 0.25 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1002 | 2 | 1.5 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1003 | 2 | 5 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1004 | 5 | 4.5 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1005 | 5 | 4.2 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1006 | 5 | 4 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1007 | 10 | 8 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1008 | 15 | 14 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1009 | 20 | 16 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1010 | 50 | 45 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1011 | 100 | 80 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1012 | 150 | 125 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1013 | 200 | 180 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1014 | 1-500 | 0,25-450 (personalizado) | 20-2000 | 99%-99.98% |

TOQUARTZ® Solucionando aplicações e desafios industriais com

Tubo de quartzo opaco aberto em ambas as extremidades

Tubo de quartzo opaco aberto em ambas as extremidades para sistemas de aquecimento por infravermelho

Principais vantagens

-

Difusão otimizada do comprimento de onda IR (5-15μm)

A estrutura de quartzo leitoso aprimora a uniformidade da radiação IV em 18% na faixa de 5-15μm. -

Gradiente térmico reduzido nas zonas de aquecimento

A opacidade da parede do tubo garante uma variação de <±3°C em 1 m de comprimento de aquecimento. -

Vida útil operacional estendida em ciclos térmicos

Mantém a integridade estrutural após mais de 1.000 ciclos entre 200°C e 1.100°C.

Solução TOQUARTZ

Um OEM alemão de equipamentos de termoformagem enfrentou problemas de aquecimento irregular, causando um desvio de ±7°C entre as zonas de aquecimento, o que levou à rejeição de 12% de produtos. Depois de mudar para os tubos de quartzo opacos TOQUARTZ®, a uniformidade da distribuição de IV melhorou em 22%, reduzindo a taxa de rejeição para menos de 3% e aumentando a vida útil do aquecedor em 40%.

Tubo de quartzo fundido opaco aberto em ambas as extremidades para equipamento de laboratório

Principais vantagens

-

Estabilidade da tolerância dimensional em altas temperaturas

Mantém a tolerância de ±0,2 mm após 50 horas a 1000°C em atmosfera inerte. -

Superfície não contaminante para reações sensíveis

A pureza de 99,98% SiO₂ garante uma lixiviação de <0,01 ppm em ambientes ácidos/básicos. -

Baixa fluorescência sob exposição a UV/IR

A superfície do tubo emite um sinal de fundo <0,5% sob excitação UV de 254 nm.

Solução TOQUARTZ

Um fabricante de instrumentos analíticos dos EUA relatou um desvio de calibração de 15% devido à interferência de fluorescência de tubos de quartzo padrão. Os tubos de quartzo opacos TOQUARTZ® reduziram o sinal de fundo em 87%, permitindo leituras estáveis durante 6 meses e reduzindo a frequência de recalibração em 50%.

Tubo de sílica fundida opaca aberto em ambas as extremidades para sistemas de esterilização por UV

Principais vantagens

-

Alta transmissão de UV-C a 185 nm (≥85%)

A opacidade controlada permite a passagem de UV-C do 87% com dispersão uniforme. -

Resistividade da superfície contra degradação induzida por UV

Taxa de degradação da superfície <0,2% após 500 horas de exposição contínua a UV-C. -

Integridade estrutural em sistemas de fluxo pressurizado

Suporta pressão interna de 1,5 bar a 80°C sem formação de microfissuras.

Solução TOQUARTZ

Um integrador de sistemas de tratamento de água japonês teve uma perda de 20% na saída de UV após 300 horas devido à degradação do tubo. Os tubos de quartzo opaco TOQUARTZ® mantiveram a saída de UV-C de 92% após 500 horas, aumentando os intervalos de manutenção em 60% e melhorando a eficiência da esterilização em 18%.

TOQUARTZ® Custom Opaque Quartz Tube Open Both Ends Services (tubo de quartzo opaco personalizado aberto em ambas as extremidades)

A TOQUARTZ® oferece serviços abrangentes de personalização para tubos de quartzo opacos, adaptados aos requisitos específicos de sua aplicação e às especificações técnicas.

Personalização dimensional

- Diâmetros externos personalizados: 1-500mm

- Diâmetros internos personalizados: 0,25-450 mm

- Comprimentos personalizados: 20-2000 mm

- Variações na espessura da parede

Modificações estruturais

- Tratamentos finais personalizados

- Extremidades alargadas ou flangeadas

- Adições à porta lateral

- Juntas de vidro fosco

Especificações do material

- Níveis de opacidade ajustáveis

- Otimização da transmissão de UV

- Níveis de pureza de até 99,995%

- Propriedades térmicas especializadas

Diretrizes de uso para tubo de quartzo opaco aberto em ambas as extremidades

O manuseio, a instalação e a manutenção adequados dos tubos de quartzo opacos são essenciais para garantir o desempenho ideal e a vida útil prolongada em aplicações industriais.

Manuseio e armazenamento

- Manuseie com luvas limpas para evitar a contaminação da superfície

- Mantenha uma folga de pelo menos 5 mm para expansão térmica

- Use juntas de silicone ou grafite para vedação

- Evite mudanças rápidas de temperatura durante o aquecimento inicial

- Use braçadeiras ou suportes de quartzo especializados

Manutenção e armazenamento

- Limpe com acetona ou álcool isopropílico, nunca com soluções alcalinas

- Inspecione regularmente quanto a microfissuras usando luz UV

- Armazenar na embalagem original ou em recipientes específicos Manter em ambiente seco (<40% de umidade)

- Substitua os tubos quando ocorrer desvitrificação visível

Maximização da vida útil

- Implemente um aumento gradual da temperatura (100°C/hora) durante os ciclos iniciais de aquecimento

- Gire os tubos 90° a cada 500 horas de operação para garantir um aquecimento uniforme

- Limpe com ácido fluorídrico diluído (5%) somente quando for absolutamente necessário e com os protocolos de segurança adequados

Precisa de assistência técnica para o tubo de quartzo opaco aberto em ambas as extremidades?

Obtenha orientação especializada sobre a seleção de materiais, especificações e soluções personalizadas.

Por que fazer parceria com a TOQUARTZ?

Vantagem da fábrica direta

Como fabricante direto, podemos eliminar os inúmeros elos intermediários.

Especialização em engenharia

A equipe técnica orienta os clientes desde a seleção do material até a otimização do projeto, traduzindo as especificações em produtos.

Fabricação flexível

Atendimento de pedidos padrão e personalizados por meio de experiência em pequenos lotes e rigor na criação de protótipos para cumprir prazos urgentes.

Qualidade

Garantia

Validação em três etapas antes da remessa:

1. precisão dimensional,

2. pureza do material,

3. limites de desempenho

Cadeia de suprimentos global

Logística global confiável para centros industriais (prioridade DE/US/JP/KR) com marcos rastreáveis.

Produtos liberados

Como um fabricante especializado com recursos de fábrica direta, a TOQUARTZ fornece soluções de quartzo padrão e personalizadas com suporte de engenharia durante todo o processo de especificação e implementação.

PERGUNTAS FREQUENTES

P: Para que é usado um tubo de quartzo opaco?

R: Os tubos de quartzo opaco (também chamados de tubos de quartzo leitoso ou translúcido) são usados principalmente em sistemas de aquecimento por infravermelho, equipamentos de esterilização por UV, aparelhos de laboratório, fornos industriais e proteção de fontes de luz. Suas principais vantagens incluem resistência a altas temperaturas (até 1200°C), excelente resistência a choques térmicos, resistência química superior e ótimas propriedades de difusão de luz, o que os torna ideais para aplicações que exigem distribuição controlada de radiação.

P: Qual é a temperatura máxima de operação para tubos de quartzo opacos?

R: Os tubos de quartzo opaco TOQUARTZ® podem operar continuamente em temperaturas de até 1100-1200°C. Para aplicações de curto prazo, eles podem suportar temperaturas de até 1450°C. O material tem um ponto de fusão de 1732°C, um ponto de amolecimento de 1630°C e um ponto de recozimento de 1180°C. É importante observar que a operação contínua próxima à temperatura máxima pode reduzir a vida útil, e os procedimentos adequados de rampa térmica devem ser seguidos para maximizar a durabilidade.

P: Qual é a resistência química dos tubos de quartzo opacos?

R: Os tubos de quartzo opaco apresentam excepcional resistência química, aproximadamente 30 vezes maior que a da cerâmica e 150 vezes maior que a do aço inoxidável quando expostos a ácidos. Eles são inertes à maioria dos produtos químicos, inclusive ácidos fortes, solventes orgânicos e gases corrosivos, especialmente em temperaturas elevadas. A única exceção significativa é o ácido fluorídrico (HF), que pode gravar e dissolver materiais à base de sílica. Essa excelente resistência química os torna ideais para equipamentos de laboratório, processamento químico e ambientes industriais agressivos.

P: Como deve ser feita a limpeza e a manutenção dos tubos de quartzo opacos?

R: Para uma manutenção ideal, limpe os tubos de quartzo opacos com acetona, álcool isopropílico ou soluções ácidas suaves (exceto HF). Evite produtos de limpeza alcalinos, pois eles podem danificar a superfície. Para depósitos persistentes, uma solução de ácido sulfúrico diluído pode ser eficaz. Sempre manuseie com luvas limpas para evitar que óleos e contaminantes afetem o desempenho. Inspecione regularmente para verificar se há desvitrificação (aparência esbranquiçada e áspera), o que indica que o fim da vida útil está se aproximando. Armazene em ambientes secos para evitar a absorção de umidade, que pode afetar o desempenho em altas temperaturas.

P: Como os tubos de quartzo opacos para aquecimento por infravermelho aumentam a eficiência energética?

R: Os tubos de quartzo opacos aumentam a eficiência do aquecimento por infravermelho por meio da difusão ideal da radiação. De acordo com estudos de eficiência térmica do International Journal of Heat and Mass Transfer, os tubos de quartzo leitoso proporcionam uma distribuição de calor até 18% mais uniforme em comparação com os tubos transparentes, o que resulta em uma economia de energia de 8-12% em aplicações de aquecimento industrial. As propriedades controladas de dispersão de luz criam temperaturas de superfície mais consistentes nos materiais-alvo, reduzindo os pontos críticos e melhorando a qualidade do processo, além de diminuir o consumo geral de energia.

Entre em contato com nossa equipe de engenharia para obter consultoria técnica e preços. Nós o ajudaremos a selecionar as especificações ideais para os requisitos de sua aplicação.