- Início

- /

- Tipos

- /

- Cubeta de quartzo

- /

- Cubeta de fluxo contínuo de quartzo

- /

- Clear Quartz Flow Through...

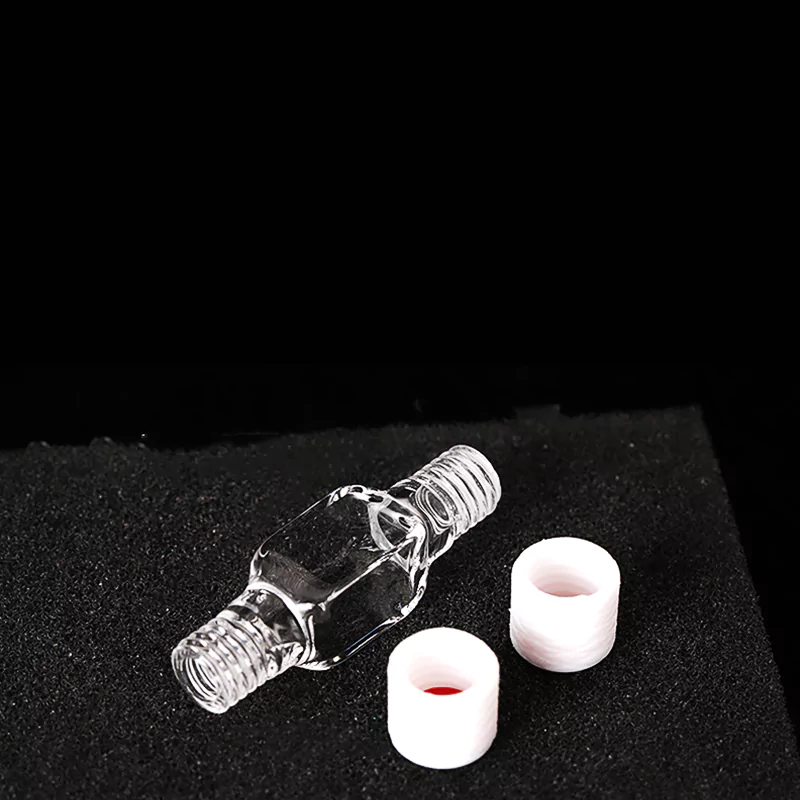

Cuvete de fluxo de quartzo transparente com conectores de rosca PTFE M10 para sistemas de injeção de fluxo -TOQUARTZ®

Características da cubeta de fluxo de quartzo transparente com conectores de rosca PTFE M10

As características do produto a seguir destacam por que a cubeta Clear Quartz Flow Through Cuvette com conector de rosca PTFE M10 é amplamente adotada em espectroscopia, detecção de fluorescência e monitoramento ambiental.

Durabilidade química contra ácidos e bases

- Resistência a ácidos e álcalis - Material de quartzo estável contra soluções de HCl, H₂SO₄ e NaOH.

- Compatibilidade com solventes - Tolerante a produtos orgânicos comuns, como etanol e acetona.

- Redução do risco de contaminação - O quartzo inerte minimiza o transporte de amostras em sistemas FIA.

Alta transmissão óptica (190-2500 nm)

- Ampla faixa de espectro - Transmissão estável de UV a NIR de 190 a 2500 nm.

- Desvio baixo da linha de base - As janelas de quartzo polido garantem uma variação de transmitância ≤0,3%.

- Comprimento preciso do caminho - Padrão de 10 mm com precisão de ±0,1 mm para resultados repetíveis.

Resistência mecânica e estabilidade térmica

- Alto módulo de fratura - ≥350 MPa, reduzindo a quebra durante o uso frequente.

- Estabilidade térmica - O corpo de quartzo suporta >1100 °C, as tampas de PTFE são adequadas para ≤200 °C.

- Longa vida útil - O coeficiente de desgaste ultrabaixo mantém a integridade em configurações de alto fluxo.

- SiO2 Pureza ≥99,98%, até 99,995%

- Resistência química a reagentes agressivos

- Serviços de personalização disponíveis

Especificações técnicas e dimensões da cubeta de fluxo de quartzo transparente com conectores roscados de PTFE M10

Especificações técnicas

| Propriedade | Especificação |

| Propriedades físicas | Densidade: 2,20 g/cm3 Índice de refração (589 nm): 1.458 Coeficiente de expansão térmica (20-1000 °C): ≤0,55×10-6/K Ponto de amolecimento: 1680 °C Condutividade térmica: 120-160 W/m-K |

| Propriedades químicas | Pureza: ≥99,98% Resistência a ácidos SiO2: Estável contra HCl, H2SO4, HNO3 Resistência a álcalis: Estável contra ≤1 M de NaOH, KOH Resistência a solventes: Tolerante ao etanol, acetona e isopropanol Compatibilidade com HF: Não é resistente ao ácido fluorídrico |

| Propriedades ópticas | Faixa de transmissão: 190-2500nm Precisão do comprimento do caminho: ±0,1 mm (10 mm nominal) Homogeneidade: ≤0,31 desvio de transmitânciaTP3T Picos de absorção: Nenhum na faixa UV-Vis Fundo de fluorescência: insignificante |

| Propriedades mecânicas | Módulo de fratura: ≥350MPa Resistência à compressão: ≥1100MPa Dureza (Mohs): 7.0 Coeficiente de desgaste: Ultrabaixo, adequado para altas taxas de fluxo |

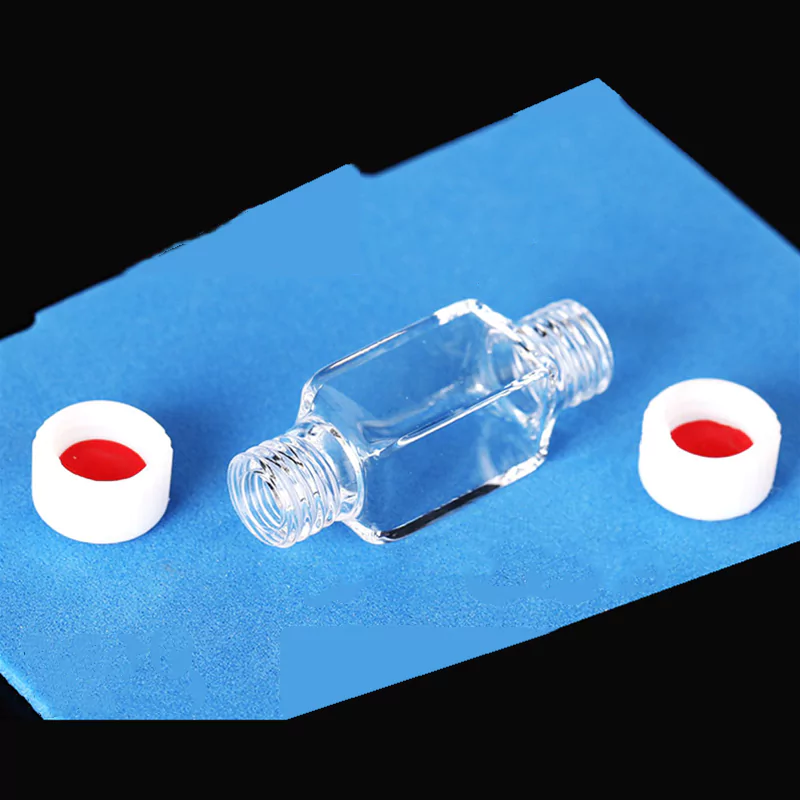

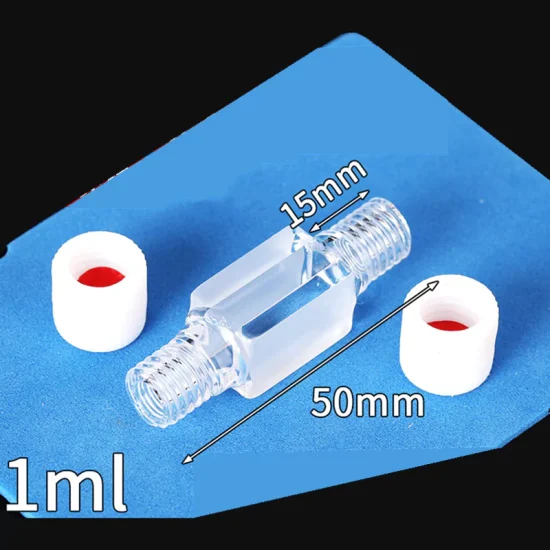

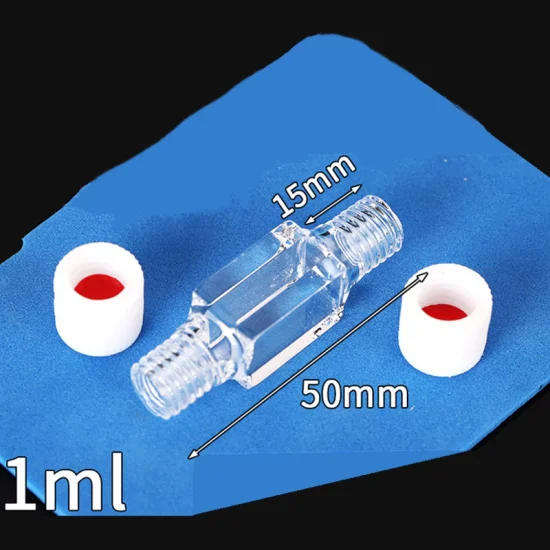

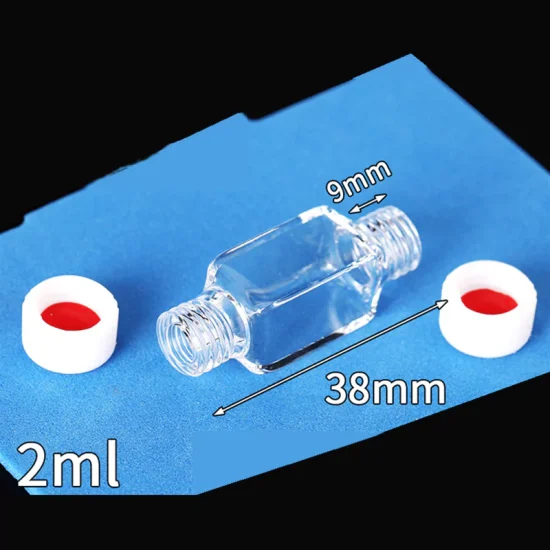

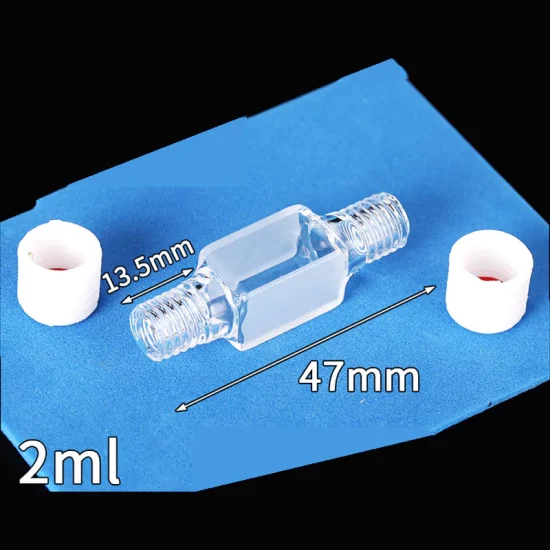

Tabela de tamanhos

| Modelo | Descrição | Caminho Comprimento |

Volume | Dimensão do contorno |

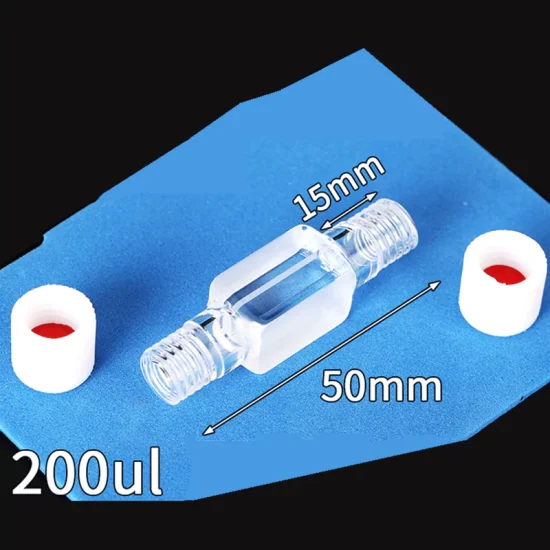

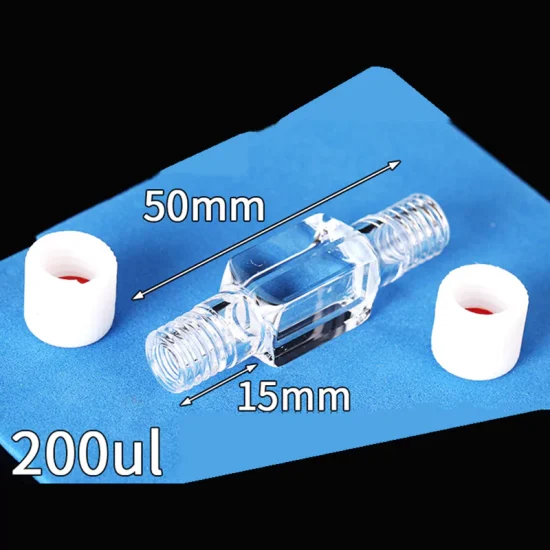

| AT-BSM-8009-3 | Cubeta de fluxo de quartzo transparente de 200μl com conector roscado de PTFE M10, janelas ópticas duplas, fenda de 1 mm | 10 mm | 200μl | 12,5×12,5×20 mm |

| Modelo | Descrição | Caminho Comprimento |

Volume | Dimensão do contorno |

| AT-BSM-8009-4 | Cubeta de fluxo de quartzo transparente de 200μl com conector roscado de PTFE M10, quatro janelas ópticas, fenda de 1 mm | 10 mm | 200μl | 12,5×12,5×20 mm |

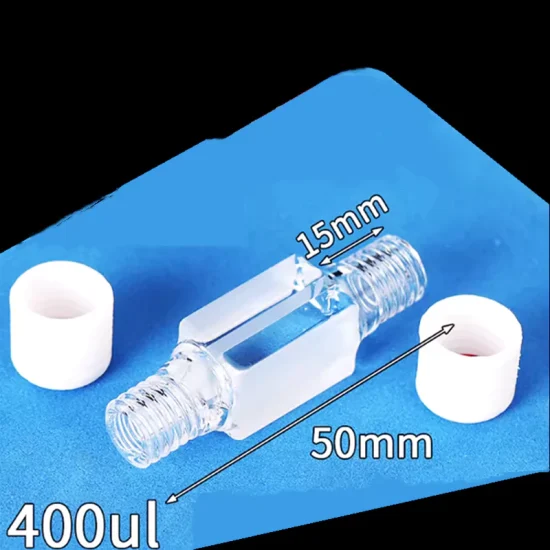

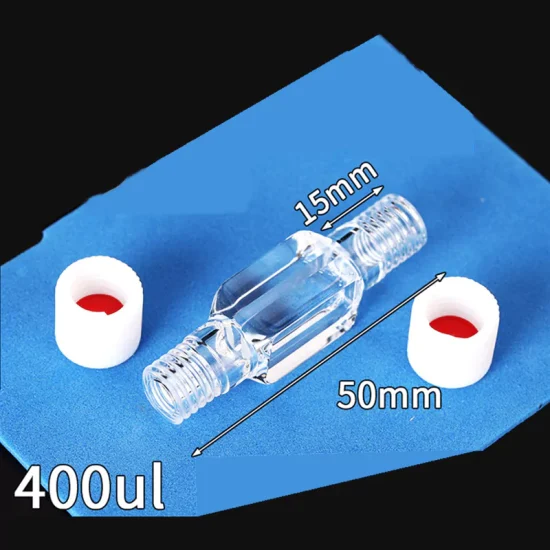

| Modelo | Descrição | Caminho Comprimento |

Volume | Dimensão do contorno |

| AT-BSM-8009-5 | Cubeta de fluxo de quartzo transparente de 400μl com conector roscado de PTFE M10, janelas ópticas duplas, fenda de 2 mm | 10 mm | 400μl | 12,5×12,5×20 mm |

| Modelo | Descrição | Caminho Comprimento |

Volume | Dimensão do contorno |

| AT-BSM-8009-6 | Cubeta de fluxo de quartzo transparente de 400μl com conector roscado de PTFE M10, quatro janelas ópticas, fenda de 2 mm | 10 mm | 400μl | 12,5×12,5×20 mm |

| Modelo | Descrição | Caminho Comprimento |

Volume | Dimensão do contorno |

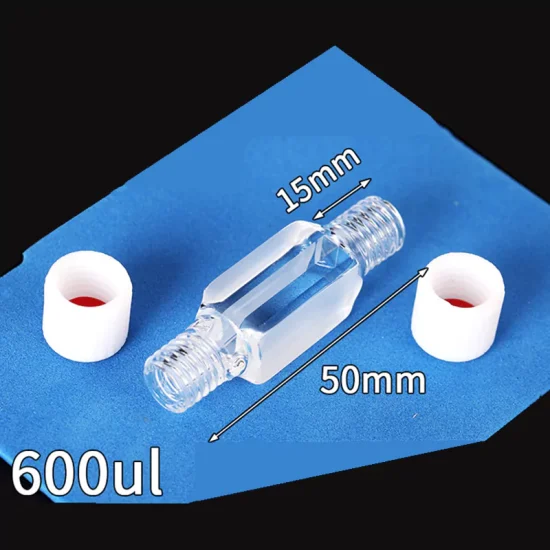

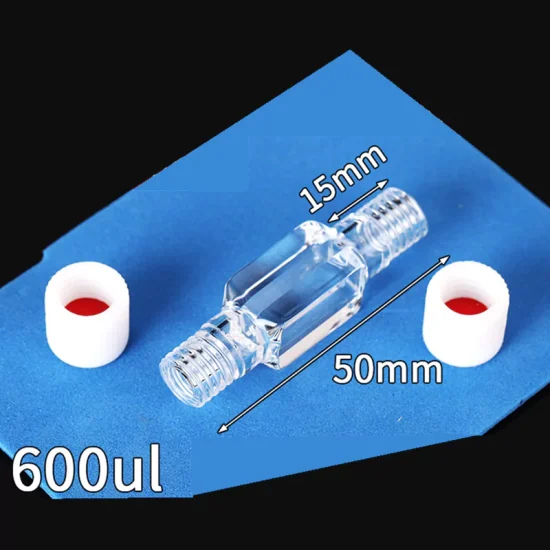

| AT-BSM-8009-7 | Cubeta de fluxo de quartzo transparente de 600μl com conector roscado de PTFE M10, janelas ópticas duplas, fenda de 3 mm | 10 mm | 600μl | 12,5×12,5×20 mm |

| Modelo | Descrição | Caminho Comprimento |

Volume | Dimensão do contorno |

| AT-BSM-8009-8 | Cubeta de fluxo de quartzo transparente de 600μl com conector roscado de PTFE M10, quatro janelas ópticas, fenda de 3 mm | 10 mm | 600μl | 12,5×12,5×20 mm |

| Modelo | Descrição | Caminho Comprimento |

Volume | Dimensão do contorno |

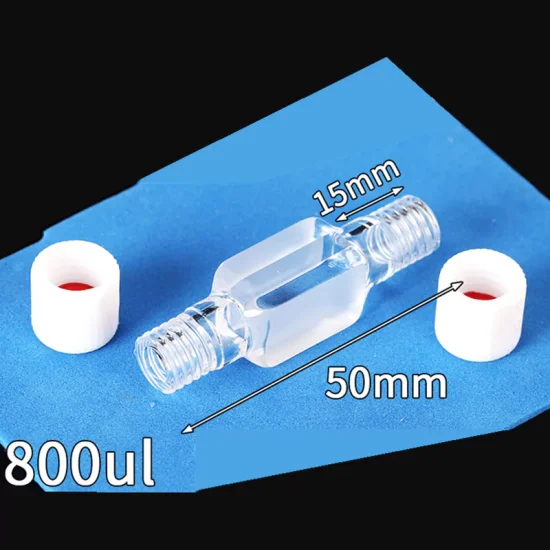

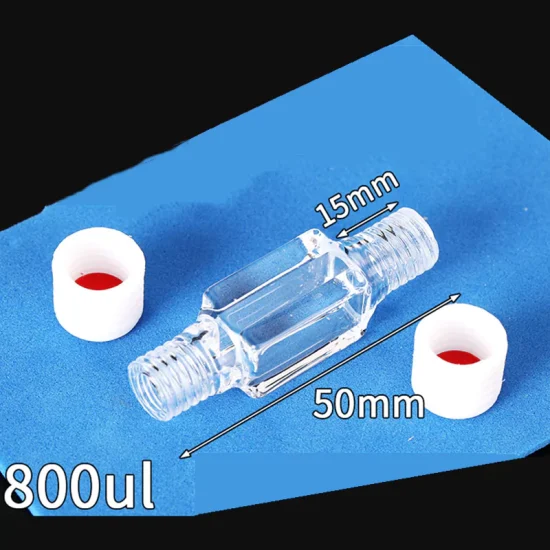

| AT-BSM-8009-9 | 800μl Clear Quartz Flow Through Cuvette com conector roscado PTFE M10, janelas ópticas duplas, fenda de 4 mm | 10 mm | 800μl | 12,5×12,5×20 mm |

| Modelo | Descrição | Caminho Comprimento |

Volume | Dimensão do contorno |

| AT-BSM-8009-10 | 800μl Clear Quartz Flow Through Cuvette com conector roscado de PTFE M10, quatro janelas ópticas, fenda de 4 mm | 10 mm | 800μl | 12,5×12,5×20 mm |

| Modelo | Descrição | Caminho Comprimento |

Volume | Dimensão do contorno |

| AT-BSM-8009-11 | Cubeta de fluxo de quartzo transparente de 1000μl com conector roscado de PTFE M10, janelas ópticas duplas, fenda de 5 mm | 10 mm | 1000μl | 12,5×12,5×20 mm |

| Modelo | Descrição | Caminho Comprimento |

Volume | Dimensão do contorno |

| AT-BSM-8009-12 | Cubeta de fluxo de quartzo transparente de 1000μl com conector roscado de PTFE M10, quatro janelas ópticas, fenda de 5 mm | 10 mm | 1000μl | 12,5×12,5×20 mm |

| Modelo | Descrição | Caminho Comprimento |

Volume | Dimensão do contorno |

| AT-BSM-8009 | Cuvete de fluxo de quartzo transparente de 2000μl com conector rosqueado PTFE M10, quatro janelas ópticas | 10 mm | 2000μl | 12,5×12,5×20 mm |

| Modelo | Descrição | Caminho Comprimento |

Volume | Dimensão do contorno |

| AT-BSM-8009-1 | Cuvete de fluxo de quartzo transparente de 2000μl com conector roscado de PTFE M10, janelas ópticas duplas | 10 mm | 2000μl | 12,5×12,5×20 mm |

| Modelo | Descrição | Caminho Comprimento |

Volume | Dimensão do contorno |

| AT-BSM-8009-2 | Cuvete de fluxo de quartzo transparente de 2000μl com conector rosqueado PTFE M10, quatro janelas ópticas | 10 mm | 2000μl | 12,5×12,5×20 mm |

TOQUARTZ® Solucionando os desafios da análise espectroscópica com a cubeta de fluxo através de quartzo transparente com conectores de rosca PTFE M10

Teste de estabilidade do eletrólito da bateria na pesquisa de energia

Principais vantagens

-

Resistência à corrosão do eletrólito

- Testado estável contra 1 M de LiPF₆ em eletrólito EC/DMC por mais de 500 horas sem lixiviação mensurável. -

Baixo desvio de absorbância

- Desvio óptico ≤0,2% ao longo de 300 ciclos contínuos no monitoramento de 254 nm. -

Confiabilidade da integração rosqueada

- Os conectores PTFE M10 mantiveram vazamento zero sob pressão de fluxo de 0,3 MPa em configurações de P&D de bateria.

Solução TOQUARTZ

Um laboratório europeu de pesquisa e desenvolvimento de baterias relatou uma tendência frequente nas curvas de absorção de UV ao usar células de fluxo de vidro devido à lixiviação iônica após 200 horas de ciclagem de eletrólitos. Ao adotar a cubeta de fluxo de quartzo transparente TOQUARTZ com conector de rosca PTFE M10, o laboratório ampliou a estabilidade do monitoramento para mais de 500 horas com precisão de absorção consistente (desvio <0,2%), eliminando a recalibração repetida e reduzindo os atrasos na validação do projeto em quase duas semanas.

Monitoramento da polimerização em linha na produção industrial de plásticos

Principais vantagens

-

Durabilidade em alta pressão

- Resistiu ao fluxo contínuo de fluxos de polímeros viscosos a 0,5 MPa sem deformação. -

Redução do acúmulo de incrustações

- O design do canal interno reduziu o acúmulo de resíduos em 30% em comparação com as células de polímero convencionais -

Estabilidade óptica no calor

- Manteve a transparência na temperatura de processo de 180 °C com desvio de absorbância <0,3%.

Solução TOQUARTZ

Um fabricante de plásticos na Coreia do Sul enfrentou várias paralisações devido à turvação e quebra de cubetas de plástico durante a polimerização contínua. Depois de mudar para a cubeta TOQUARTZ Clear Quartz Flow Through Cuvette com conector rosqueado PTFE M10, o monitoramento da absorbância em linha permaneceu estável por mais de 1.000 horas de produção. O acúmulo de incrustações foi reduzido em 30%, economizando aproximadamente US$ 40.000 por ano em custos de substituição e tempo de inatividade.

Controle de cores e aditivos na fabricação de vidros especiais

Principais vantagens

-

Alta resistência térmica

- Operou de forma estável a 950 °C sem distorção da janela durante o monitoramento de aditivos fundidos. -

Detecção de aditivos de precisão

- Repetibilidade de absorbância alcançada dentro de ±0,15% para concentração de dopante Fe³⁺ a 400 nm. -

Monitoramento livre de contaminação

- A superfície inerte de quartzo impediu a contaminação iônica mensurável em testes de lote.

Solução TOQUARTZ

Uma fábrica de vidros especiais na Alemanha sofreu rejeições frequentes de produção (perda de lote de ≈8%) devido ao monitoramento inconsistente do dopante com células de fluxo de metal, que corroíam sob alta temperatura. A implementação da cubeta de fluxo TOQUARTZ Clear Quartz com conector de rosca PTFE M10 reduziu o erro de medição de absorbância para ±0,15% e diminuiu as taxas de rejeição de lote em 70%, o que equivale a uma economia anual de mais de €120.000.

Soluções de personalização para suas aplicações específicas

Opções de geometria óptica

A personalização da geometria óptica aumenta a precisão da medição em diversas aplicações.

-

Comprimento do caminho

- Ajustado para se alinhar aos requisitos do sistema analítico. -

Design de janelas

- Configurado para necessidades de medição de absorbância ou de feixe duplo. -

Acabamento óptico

- Polido para reduzir a dispersão e o controle estável da linha de base.

Configurações de canais de fluxo

Estruturas de canal personalizadas otimizam o manuseio de fluidos em análises contínuas.

-

Largura do canal

- Adaptado para equilíbrio da sensibilidade e estabilidade da pressão. -

Controle de volume

- Projetado para minimizar o transporte e o desperdício de amostras. -

Dinâmica de fluxo

- Otimizado para o movimento consistente do líquido sem turbulência.

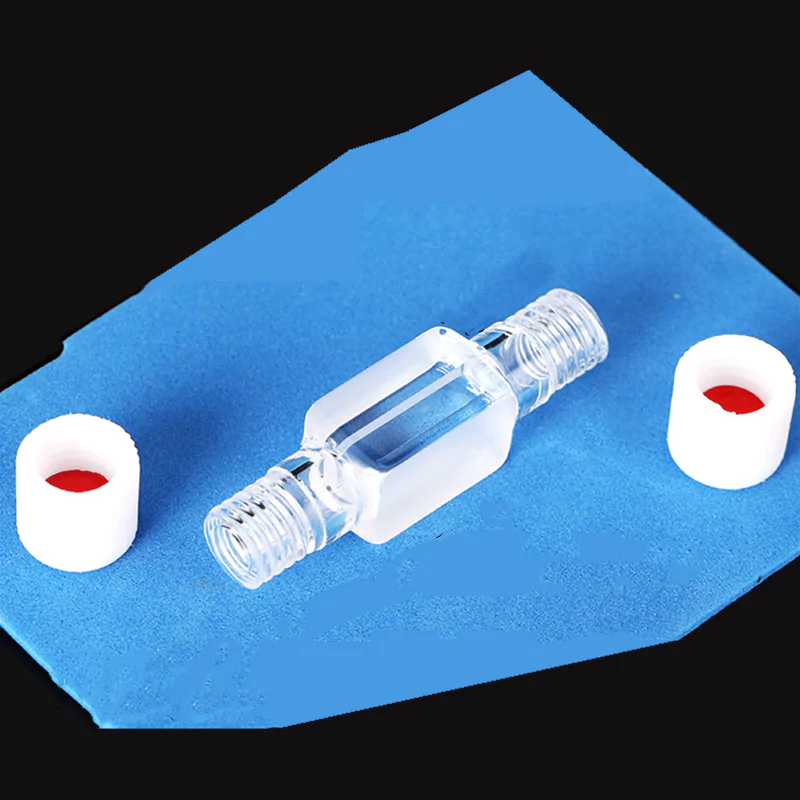

Adaptações de conectores e vedações

A personalização do conector garante uma integração confiável com diversos sistemas de tubulação.

-

Design de linha

- Configurado para um ajuste seguro com coletores industriais. -

Opções de vedação

- Selecionado para compatibilidade química com fluidos de teste. -

Material da tampa

- Escolhido para suportar o uso rotineiro e o aperto repetido.

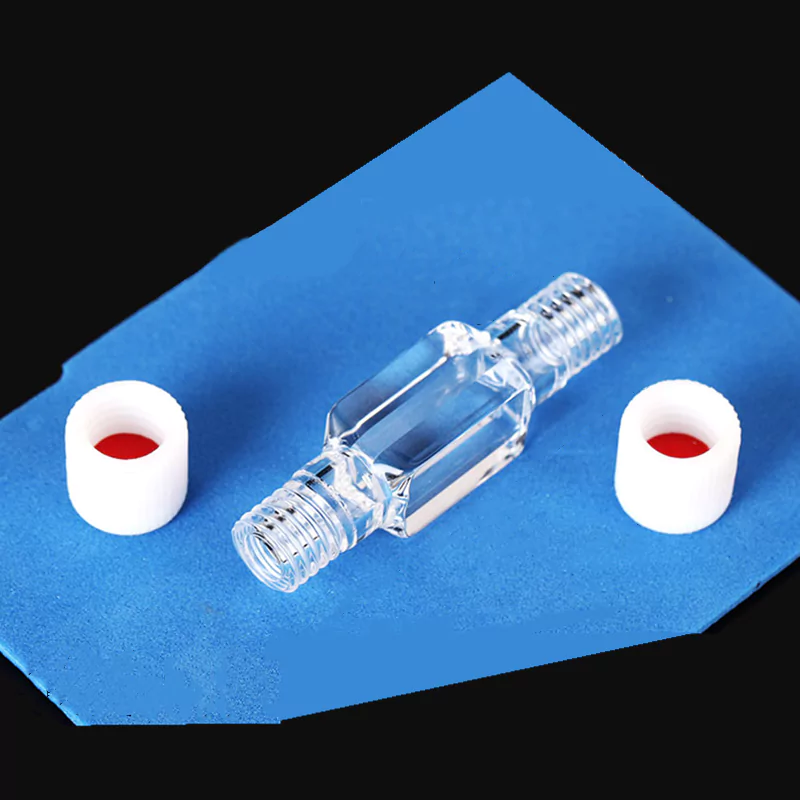

Diretriz de uso do produto

Etapas de operação adequada

- Sempre instale a cubeta usando os conectores roscados PTFE M10 para garantir uma vedação sem vazamentos.

- Mantenha uma taxa de fluxo constante para evitar choques de pressão que possam estressar o corpo de quartzo.

- Verifique o alinhamento óptico antes de iniciar as medições para reduzir o desvio da linha de base.

- Use tubos e coletores compatíveis para evitar tensão nas conexões rosqueadas.

Limpeza e manutenção

- Enxágue imediatamente com água deionizada após cada uso para evitar o acúmulo de resíduos.

- Aplique uma solução detergente de pH neutro por 15 a 20 minutos para dissolver os depósitos orgânicos.

- Lave com isopropanol para remover a água e acelerar a secagem.

- Evite materiais abrasivos ou escovas afiadas que possam arranhar as janelas de quartzo.

Recomendações de armazenamento e manuseio

- Armazene a cubeta em um recipiente livre de poeira com tampas protetoras nas roscas M10.

- Mantenha-o longe da luz solar direta e de temperaturas extremas para manter a clareza óptica.

- Coloque a cubeta verticalmente durante o armazenamento para evitar estresse nas janelas ópticas.

- Inspecione as vedações de PTFE regularmente e substitua-as se observar deformação ou desgaste.

Solução de problemas comuns

- Se as leituras ópticas mostrarem alto ruído, verifique se as janelas estão livres de resíduos.

- Em caso de vazamento, verifique se as tampas de PTFE M10 estão apertadas uniformemente e se as vedações estão intactas.

- Se ocorrer desvio de absorbância, confirme o posicionamento correto do comprimento do caminho no instrumento.

- Para bloqueios de fluxo, inspecione os canais quanto a depósitos e repita o ciclo completo de limpeza.

Agilize os resultados com a cubeta de fluxo de quartzo transparente com conector roscado de PTFE M10

Entre em contato conosco hoje mesmo para garantir um desempenho confiável para seus sistemas analíticos.

Por que fazer parceria com a TOQUARTZ?

Vantagem da fábrica direta

Como fabricante direto, podemos eliminar os inúmeros elos intermediários.

Especialização em engenharia

A equipe técnica orienta os clientes desde a seleção do material até a otimização do projeto, traduzindo as especificações em produtos.

Fabricação flexível

Atendimento de pedidos padrão e personalizados por meio de experiência em pequenos lotes e rigor na criação de protótipos para cumprir prazos urgentes.

Qualidade

Garantia

Validação em três etapas antes da remessa:

1. precisão dimensional,

2. pureza do material,

3. limites de desempenho

Cadeia de suprimentos global

Logística global confiável para centros industriais (prioridade DE/US/JP/KR) com marcos rastreáveis.

Produtos liberados

Como um fabricante especializado com recursos de fábrica direta, a TOQUARTZ fornece soluções de quartzo padrão e personalizadas com suporte de engenharia durante todo o processo de especificação e implementação.

PERGUNTAS FREQUENTES

P: O que torna a Clear Quartz Flow Through Cuvette com conector roscado de PTFE M10 adequada para análise de fluxo contínuo?

R: Suas paredes de quartzo transparente proporcionam transmissão óptica estável de 190 a 2500 nm, ideal para medições de absorção. Os conectores roscados PTFE M10 permitem uma operação sem vazamentos, mesmo sob fluxo constante de líquido. Combinado com canais de baixo volume morto, ele garante um rendimento eficiente da amostra com o mínimo de transporte.

P: Como a cubeta Clear Quartz Flow Through Cuvette com conector roscado de PTFE M10 se integra aos sistemas de fluidos laboratoriais?

R: Os conectores de parafuso PTFE M10 são compatíveis com sistemas comuns de tubulação e coletores. Esse projeto minimiza a necessidade de adaptadores adicionais, reduzindo os pontos de vazamento na configuração. A rosca segura também resiste a ciclos repetidos de conexão e desconexão.

P: A Clear Quartz Flow Through Cuvette com conector roscado de PTFE M10 pode ser usada com amostras ácidas ou básicas?

R: O corpo de quartzo oferece excelente resistência a ácidos e bases fortes, apoiando aplicações em análises ambientais e químicas. Os conectores de PTFE aumentam ainda mais a compatibilidade com reagentes agressivos. Entretanto, ele não deve ser usado com soluções de ácido fluorídrico.

P: A cubeta Clear Quartz Flow Through Cuvette com conector roscado de PTFE M10 pode ser esterilizada?

R: O corpo de quartzo resiste à esterilização em autoclave acima de 1100 °C, garantindo a durabilidade em ambientes estéreis. As tampas de PTFE, entretanto, limitam as condições de trabalho a cerca de 200 °C. Para a maioria dos protocolos de esterilização de laboratório, essa combinação oferece resistência suficiente.

P: Qual é a durabilidade da cubeta Clear Quartz Flow Through Cuvette com conector roscado de PTFE M10 em caso de uso repetido?

R: Com um módulo de fratura de ≥350 MPa, o corpo de quartzo resiste à quebra sob ciclos de fluxo repetidos. Os conectores de parafuso de PTFE suportam o aperto frequente sem deformação. Em geral, os clientes atingem mais de 100.000 ciclos em condições padrão de laboratório.

Entre em contato com nossa equipe de engenharia para obter consultoria técnica e preços. Nós o ajudaremos a selecionar as especificações ideais para os requisitos de sua aplicação.