- +86 19311583352

- info@toquartz.com

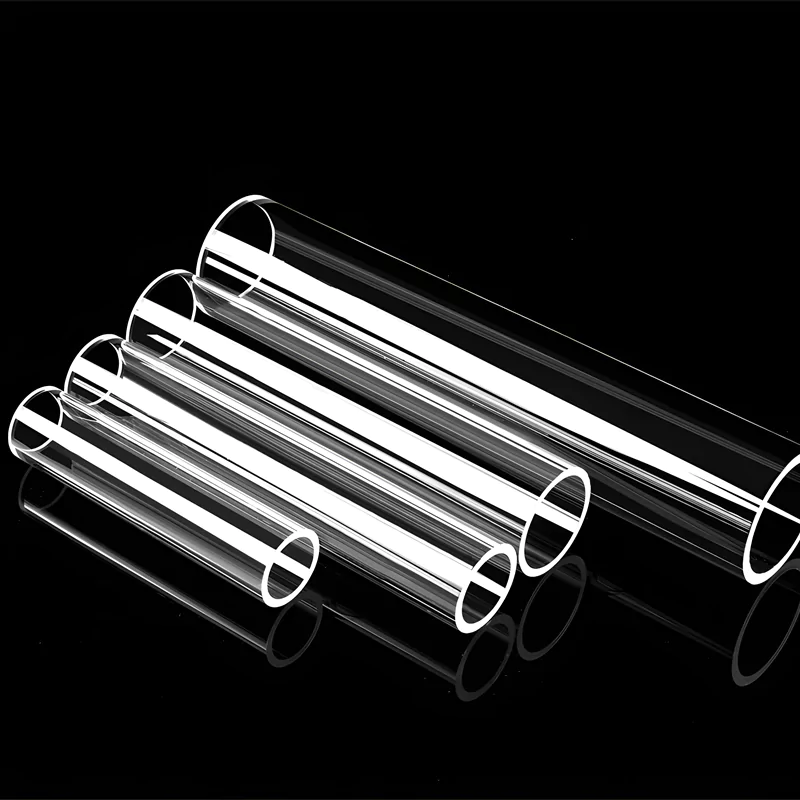

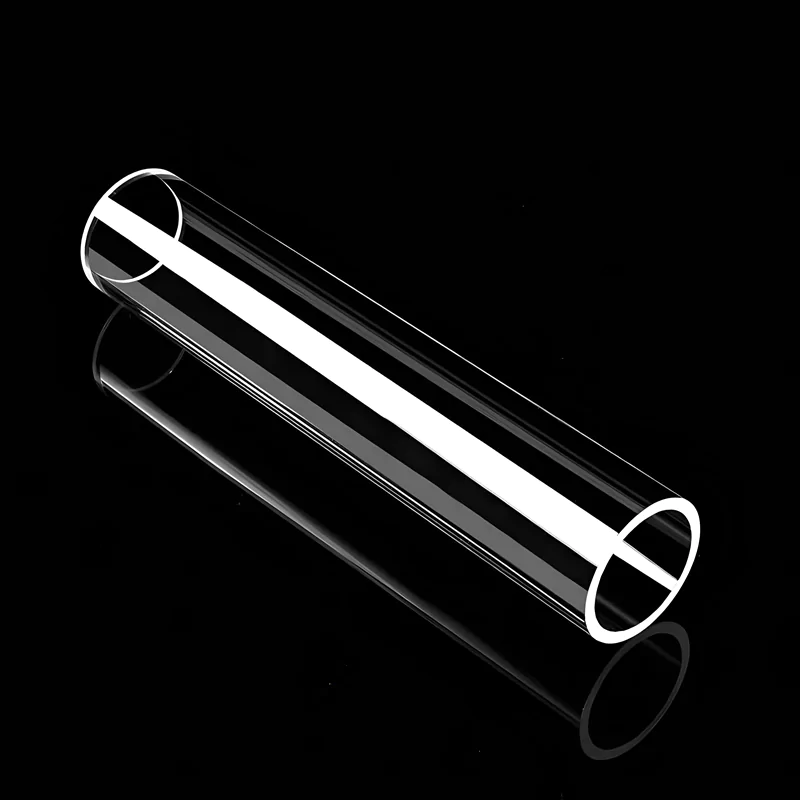

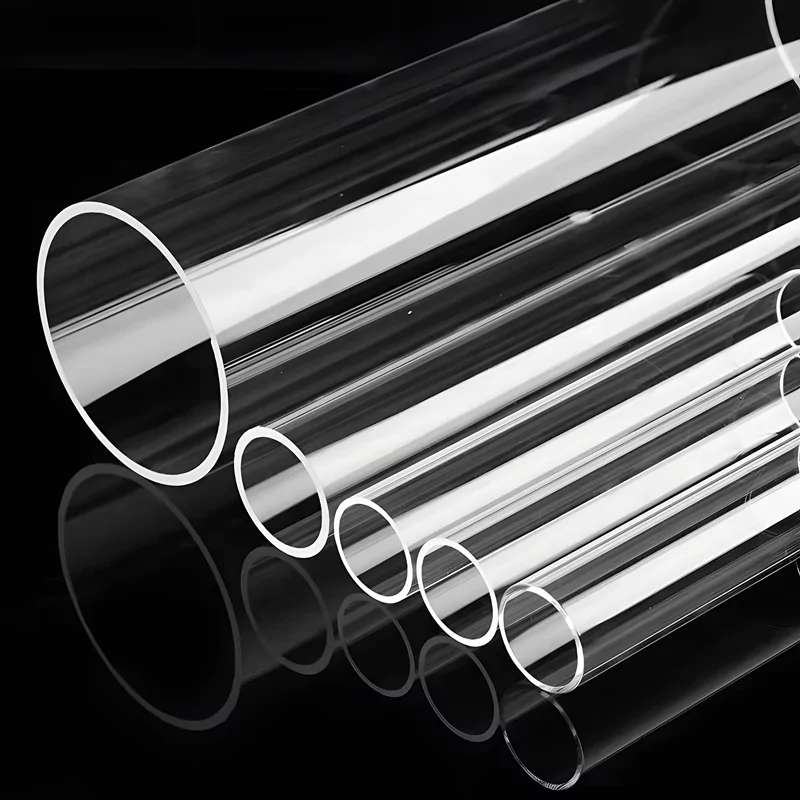

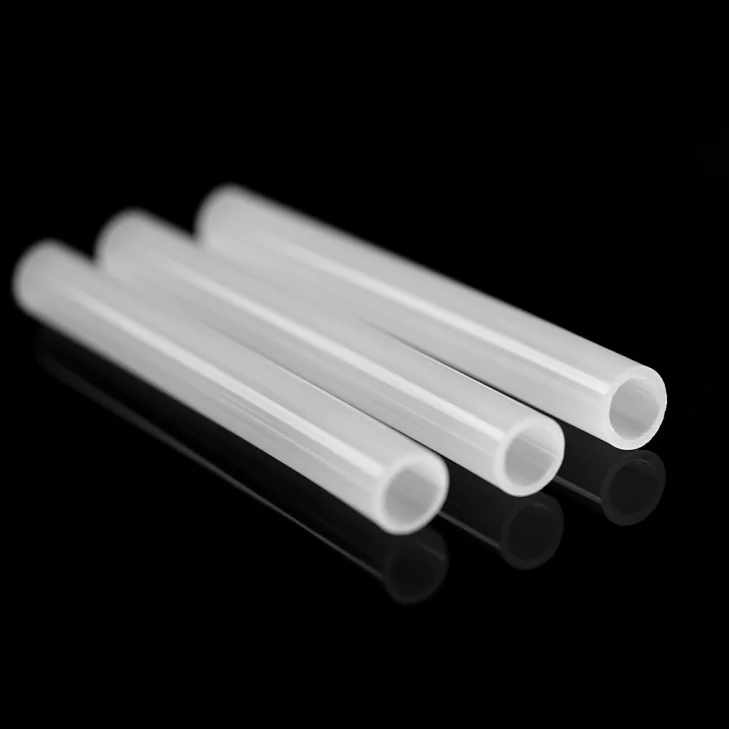

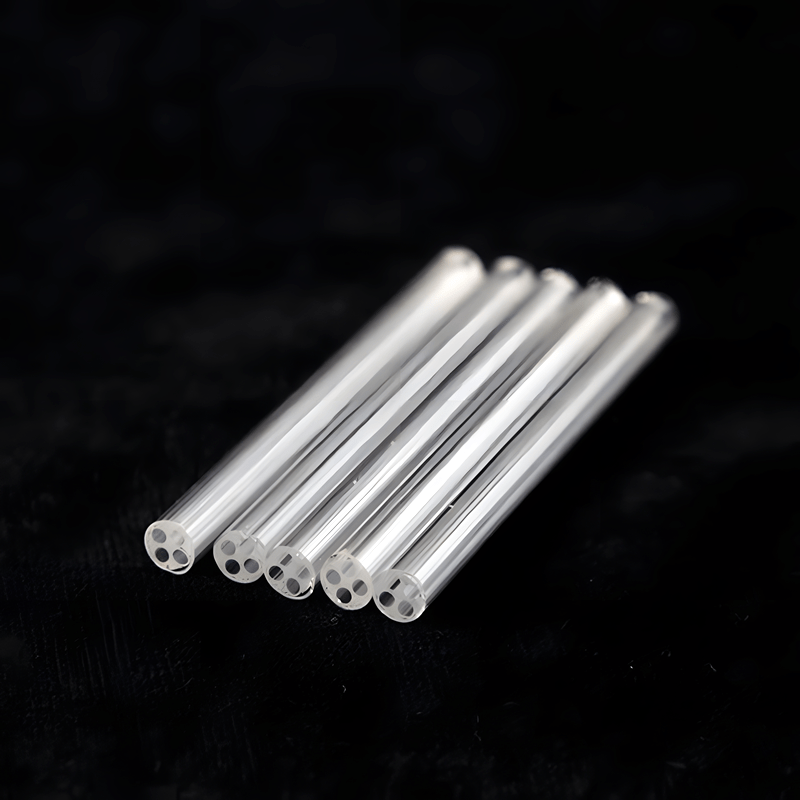

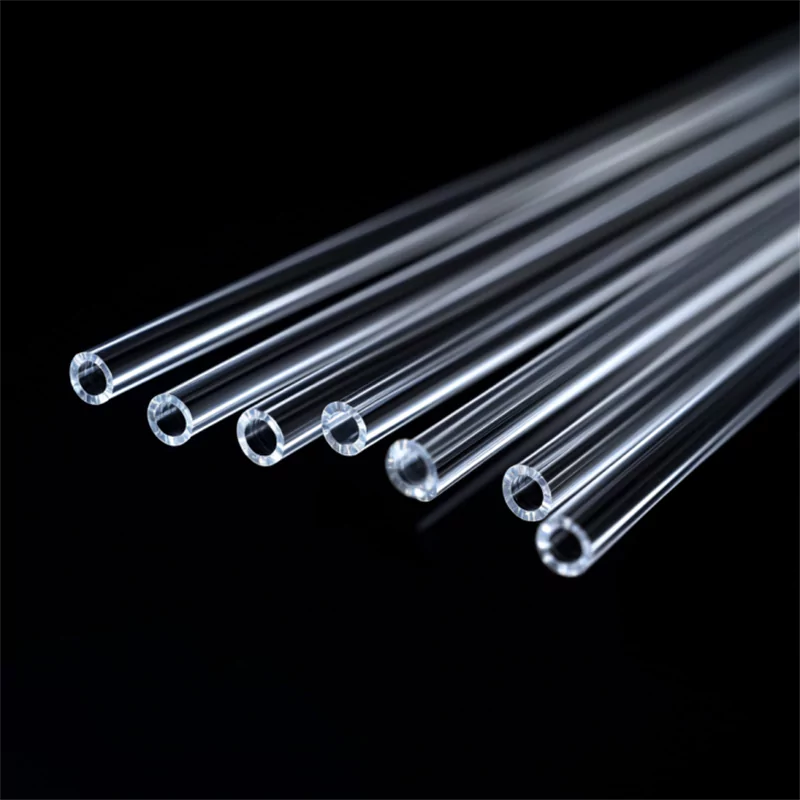

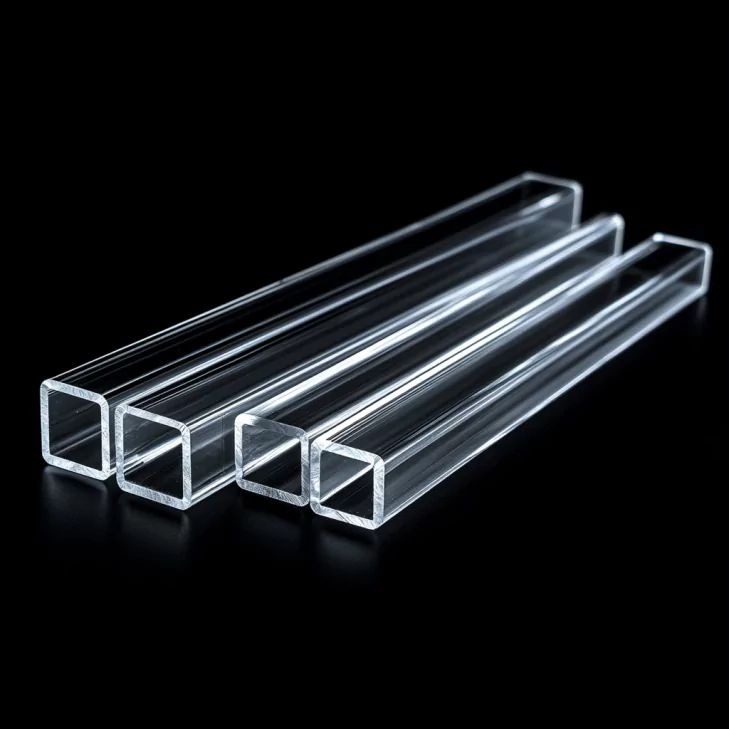

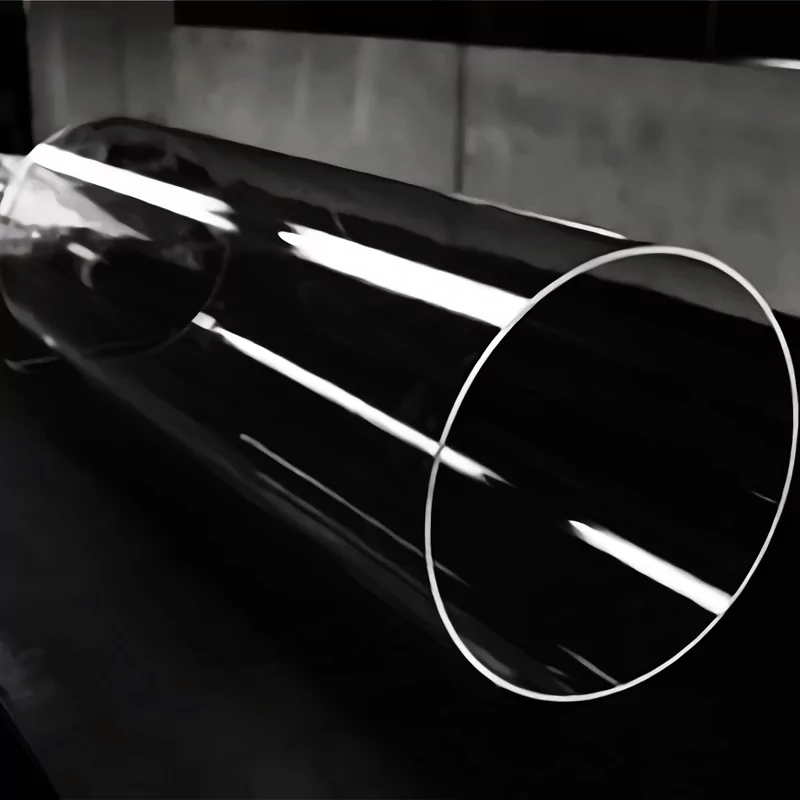

Custom Quartz Tubes Manufacturer in China

- Receive First Custom Sample in 5 Days

- Small Batch-Flexible for Trials and Production

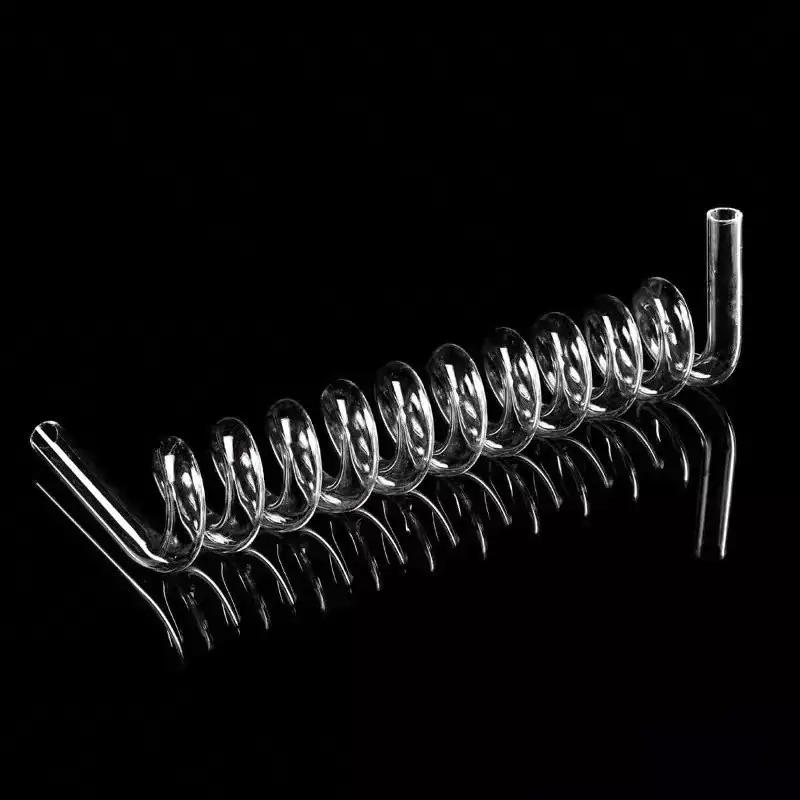

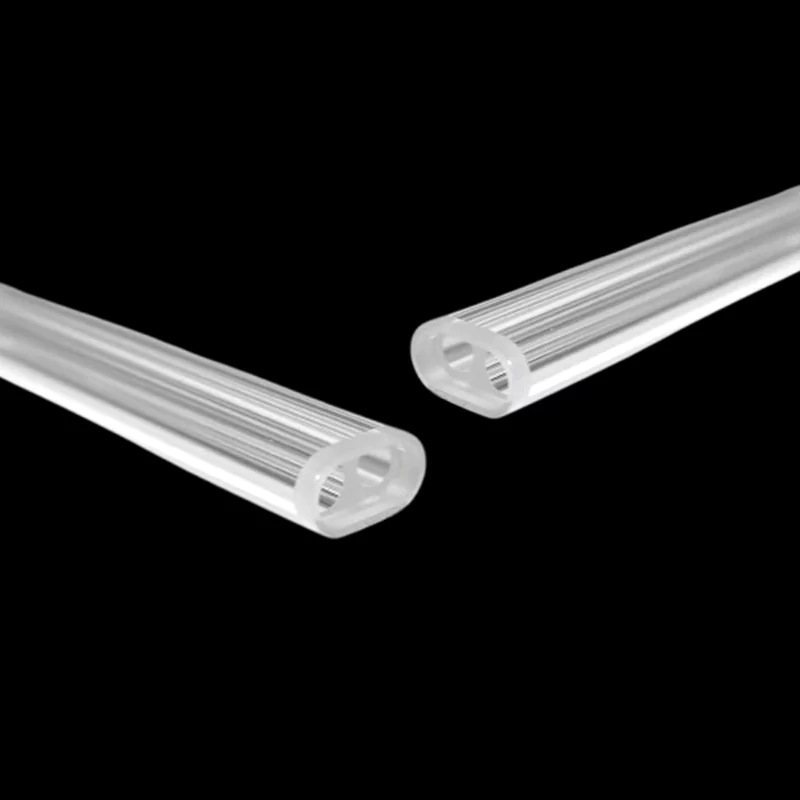

- Custom OD/ID, Slotting, Bending, and Sealing Available

- Engineered for Lab, UV/IR Optics & Industrial Demands

- Sandard Sizes In Stock

Best Applications for Precision Quartz Tubes

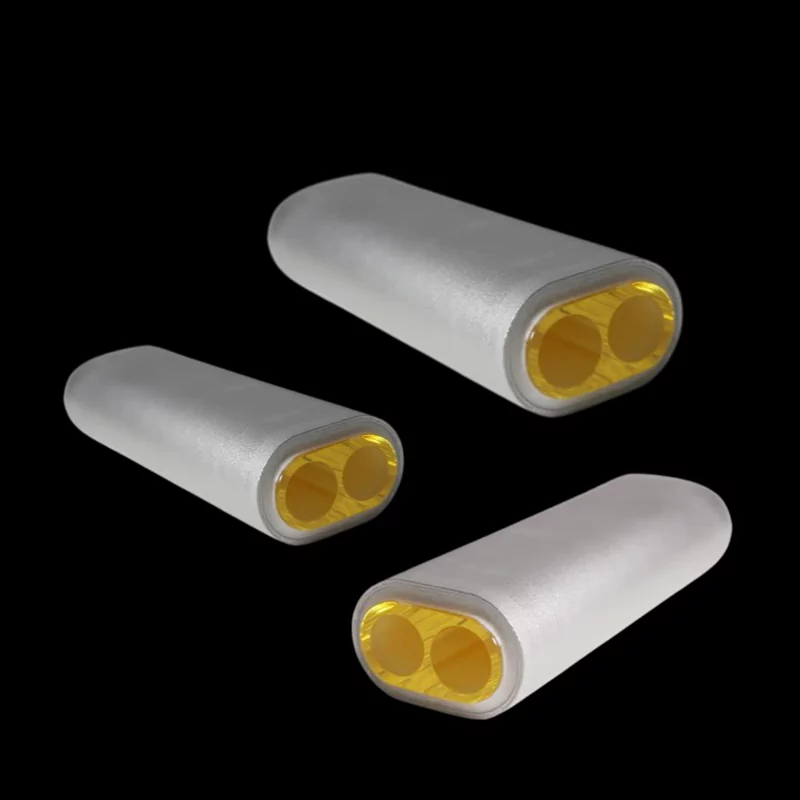

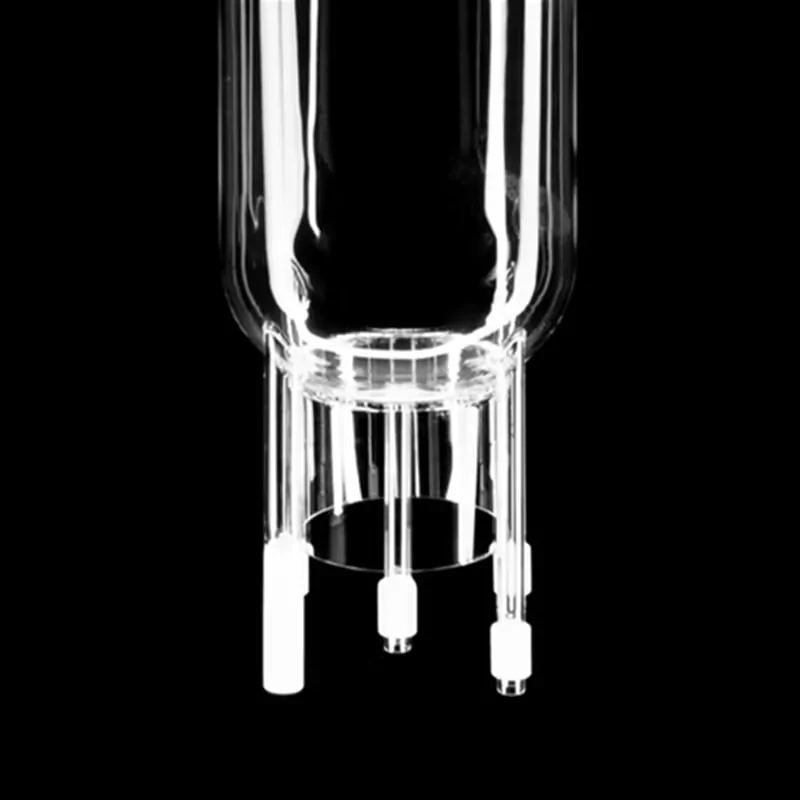

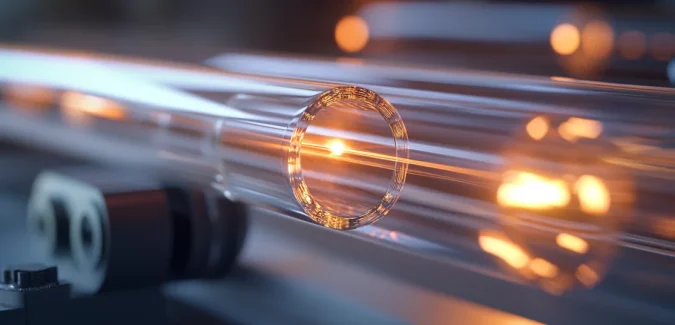

Custom Lab Quartz Tube for Extreme Conditions

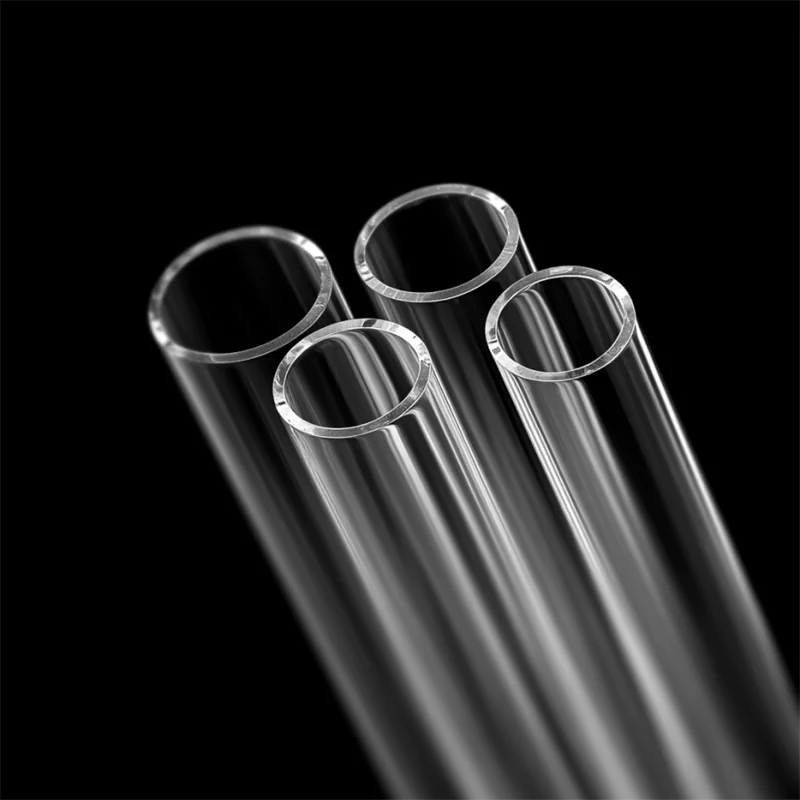

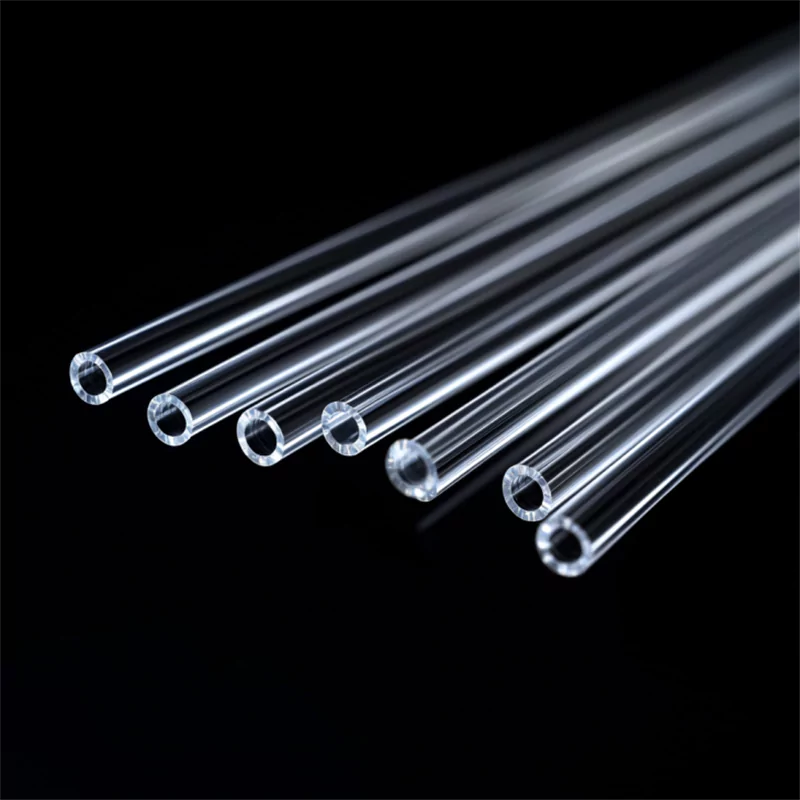

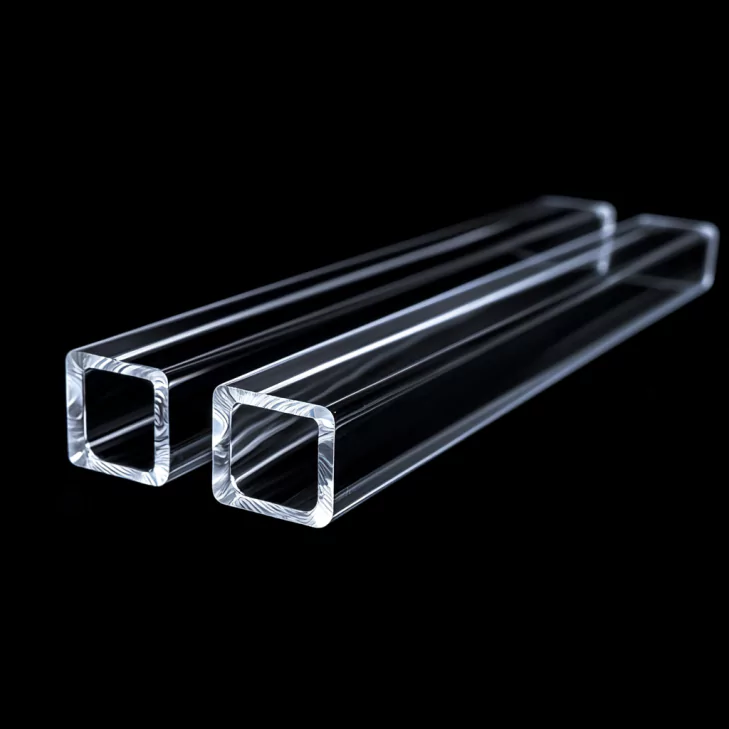

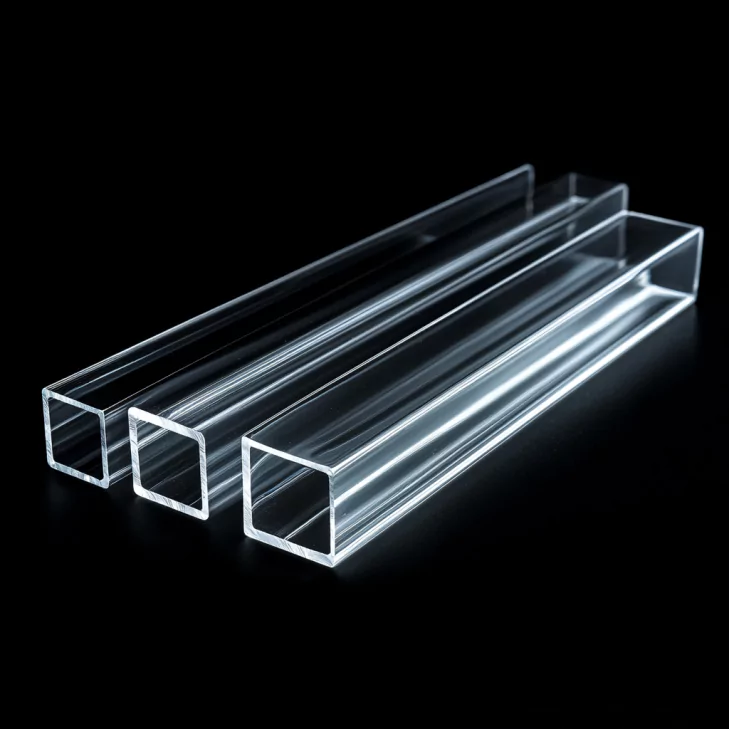

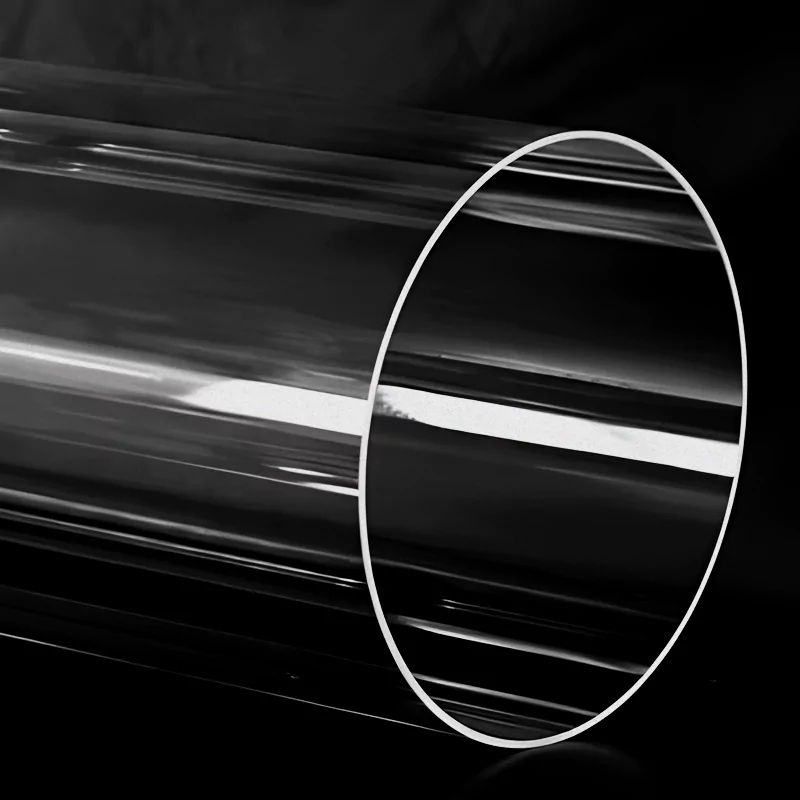

Customized Optical-Grade Quartz Tube

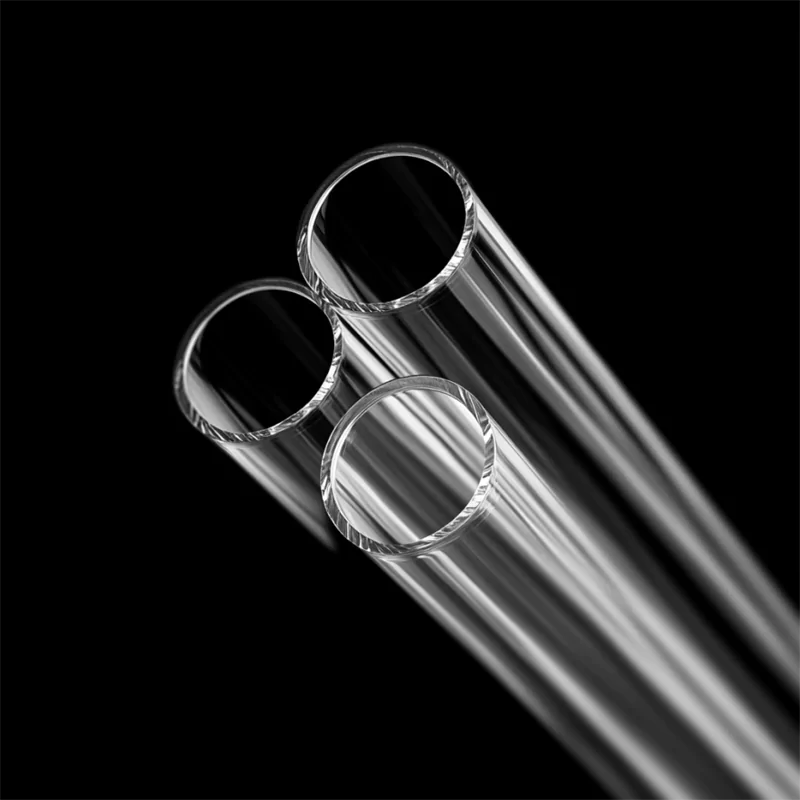

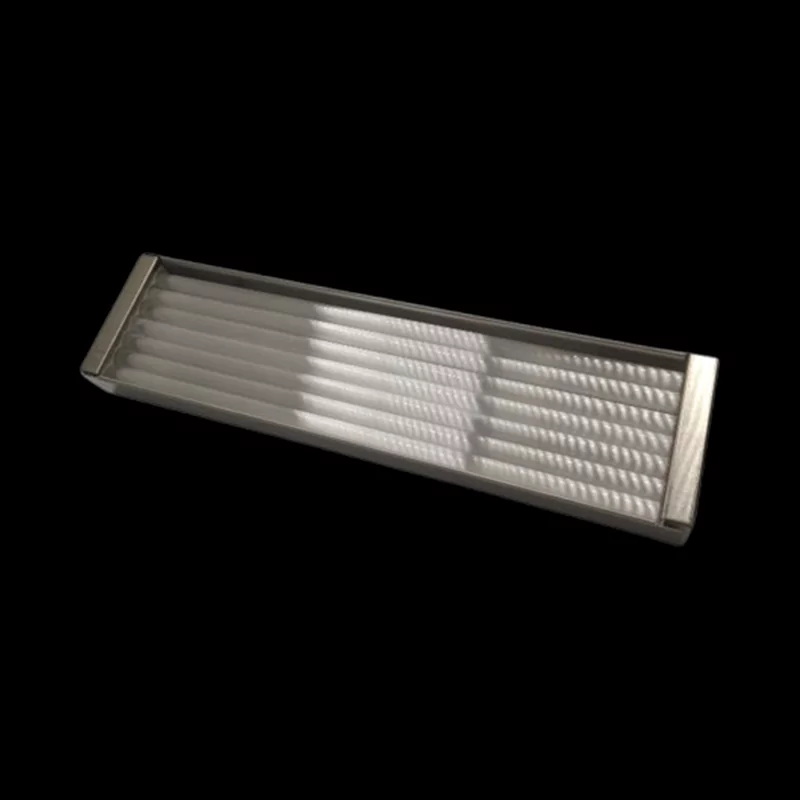

Custom Industrial Quartz Tube Parts for Harsh Environments

99.98% SiO₂ Guaranteed

1,250°C Short-Term Thermal Tolerance

1,100℃ Extreme Heat Endurance

TOQUARTZ® Quartz Tube Precision Customization Capabilities

To provide a clear overview of our capabilities, we have detailed our parameters below, ensuring you can quickly find the information you need.

| Category | Parameter | Option / Grade | Specification / Description |

| 1. Material Grade & Performance | Material Purity | Standard Grade (3N) | 99.99% SiO₂ |

| High-Purity Grade (4N) | 99.995% SiO₂ | ||

| Material Type | Far UV Grade (JGS1) | OH < 5ppm, >85% Transmission @ 185nm | |

| UV Grade (JGS2) | OH ~150-200ppm, for applications >220nm | ||

| IR Grade (JGS3) | OH < 1ppm, no absorption peak @ 2.73μm | ||

| Opaque / Milky Quartz | >95% IR reflectivity, excellent thermal insulation | ||

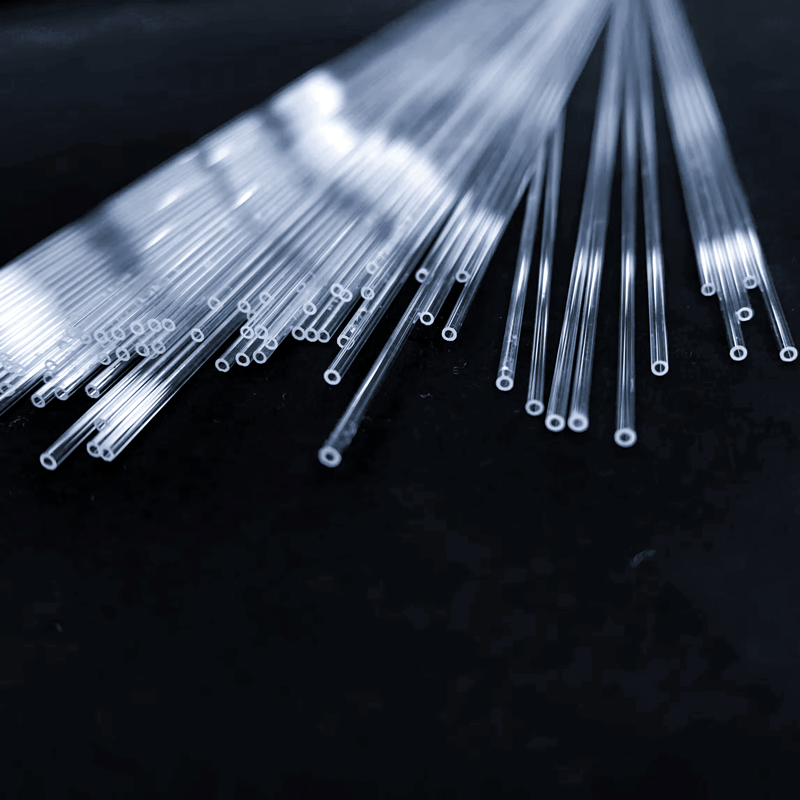

| 2. Geometric Dimensions | Outer Diameter (OD) | Standard Range | 1.5mm – 450mm |

| Length | Standard Range | 20mm – 2000mm | |

| 3. Tolerances | Diameter Tolerance | Standard | ±0.5% of Diameter |

| Precision | ±0.1mm | ||

| Ultra-Precision | Down to ±0.02mm (depending on tube diameter) | ||

| Wall Thickness Tolerance | Standard | ±10% of Wall Thickness | |

| Precision | Down to ±0.1mm | ||

| Length Tolerance | Standard Cut | ±0.5mm | |

| Precision Grinding | Down to ±0.1mm | ||

| Straightness | Standard | ≤ 2mm / meter | |

| High Precision | ≤ 0.5mm / meter | ||

| 4. End & Body Fabrication | End Finish | Flame Polishing | Smooth, rounded edges; stress-relieved |

| Cutting & Grinding | Flat end face, perpendicularity < 0.5°, for bonding/sealing | ||

| Chamfering | 45° or custom angle; prevents chipping, aids assembly | ||

| Sealing Shape | Flat Bottom Seal | – | |

| Round Bottom Seal | – | ||

| Domed / Hemispherical Seal | – | ||

| Advanced Machining | Flanges, Threads, Holes, etc. | Precision fabrication per customer drawings | |

| 5. Surface & Optical Properties | Surface Roughness (Ra) | Standard Drawn | ~1μm |

| External Grinding | ~0.8μm | ||

| Optical Polishing | < 0.2μm | ||

| Surface Treatment | AR Coating | >99% transmission in specific wavebands | |

| Reflective (HR) Coating | Metal (Al, Au) or dielectric films | ||

| Frosted / Sandblasted | Creates a uniform diffusing surface | ||

| 6. Thermal Treatment & Services | Annealing | Precision Annealing | Reduces internal stress to < 4 nm/cm |

| Laser Marking | Non-Contact Engraving | Logos, serial numbers, etc. Min. character height: 0.5mm |

TOQUARTZ® Engineered Excellence in

Quartz Glass Tube Manufacturing

Ultra-High Purity for Laboratory Precision Purity (99.98% SiO₂)

Ensures fused quartz tubes eliminate trace metal contamination (e.g., Fe, Na ≤1.5ppm) critical for sensitive lab workflows like pharmaceutical synthesis or ICP-MS analysis cell liners.

(TOQUARTZ® max. purity can up to 99.995%)

Mechanical Stability in High-Temperature Industry Elastic Modulus (72 GPa) + Compressive Strength (1100 MPa)

Allows quartz tubes to resist creep deformation in vertical industrial reactors at 1100°C continuous operation.

Optical Clarity for Precision Systems Refractive Index (1.4585) +Transmission (≥93% @280-780nm)

Makes fused quartz glass tubes ideal for UV lithography lasers and medical sterilization devices, ensuring undistorted light propagation.

Precision Quartz Tube Custom Manufacturing

Direct factory supply — no middlemen, better cost control .

Dedicated engineering team — fast response on drawings & specs.

Efficient logistics — Support DDP, FOB, CIF terms

Need Solutions Beyond Common Applications?

Get Free Expert Advice on Your Custom Fused Quartz Tubing Project!

Flexible Quantity & Price

Volume-Based Tiered Discounts

Enjoy wholesale quartz tubes savings upon specific request, generally 10% off for 100+ units, 20% off for 500+ units.

No MOQ Restrictions

Buy quartz tubing with flexible pricing and no minimum order requirements, scaling from 1-unit prototypes to bulk quartz tubing supply.

Why Engineers & Procurement Managers Choose TOQUARTZ

- 99.98 purity(TOQUARTZ® max. purity can up to 99.995%)

- 3-Day feasibility validation

- 1 MOQ

- 93%+ spectral uniformity

- 1,100℃ endurance

- 7-day urgent turnaround

- 99.9% SiO₂ purity

- 40-day custom lead time

- 2000+ MOQ pressure

- 88% UV transmittance

- 1000℃ sustained tolerance

- 35%+ delayed urgent orders

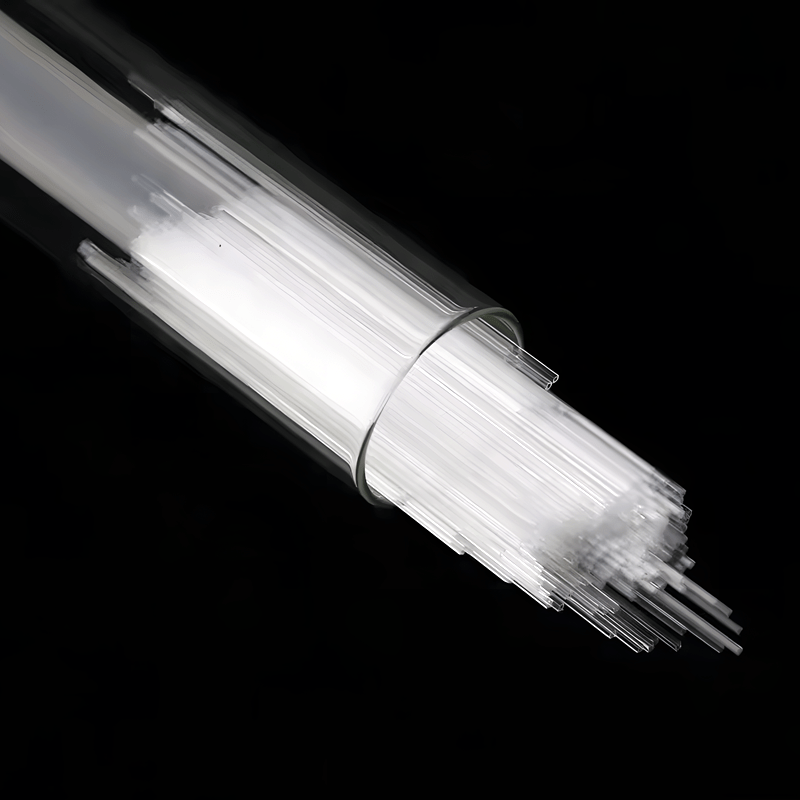

Enduring Quartz Tubing Supply Chain Solutions

About TOQUARTZ

TOQUARTZ has pioneered precision customized quartz tubes engineered for lab, industrial, and optical excellence. As a leading quartz tube manufacturer, we supply quartz tubes without MOQ constraints, paired with rapid prototyping. Trusted by innovators in optics R&D, chemistry labs and Industrial, we’ve redefined the quartz glass tube market by bridging precision and accessibility.

TOQUARTZ, a reliable quartz tubing supplier, guarantees NO-MOQ wholesale fused quartz glass tubing and offers flexible volume tiered pricing backed by streamlined operations, global partnerships, and scalable production. Below are the strategic advantages enabling our flexible quartz tubing supply.

All-Stage Material Control

End-to-end oversight of Fused Quartz Tube from smelting to annealing.

Critical Inventory Buildup

Fast-track regional stock buffers of Quartz Tubing, slashing lab procurement delays by 40% vs competitors.

Damage-Proof Logistics Guarantee

Military-grade crates + 100% insured shipments for fragile Quartz Glass Tubes.

Dual-Supplier Risk Eradication

Two validated material streams for our Fused Quartz Tubing, maintaining 99.8% on-time fulfillment.

End-to-End Service Mastery for Every Quartz Tubing Challenge

24/7 Priority Engineering Support

Custom fused quartz tubing inquiries resolved within <24 hours.

3 Week-Day Expedited Prototyping

Quartz tubes production accelerated via AI-driven scheduling, achieving 72-hour turnaround for urgent orders.

Comprehensive After-Sales Protection

We offer technical support, responsive troubleshooting services, and performance optimization recommendation for your quartz tubing supply needs.

Samples available at cost price!

Get in touch with us today to receive personalized quartz glass tube pricing and expert advice tailored to your specific requirements. Let us help you find the perfect solution for your business!

Your Custom Quartz Solution in Just 3 Steps:

1.Send Specifications: Upload drawings or discuss requirements

2.Approve Design: Review our detailed technical proposal

3.Receive Product: Quality-assured delivery, typically within 1 week.